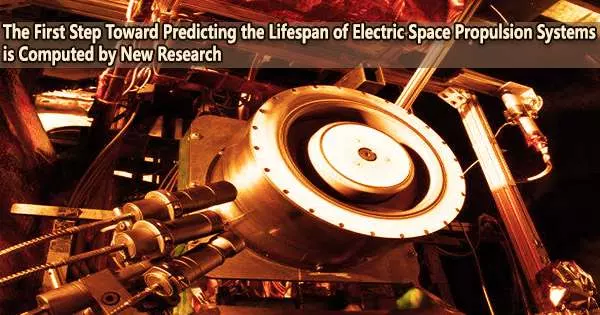

An electric space propulsion system is a type of spacecraft propulsion technology that uses electric power to accelerate a spacecraft. Unlike chemical propulsion systems that rely on the combustion of fuel and oxidizer, electric propulsion systems use electric fields or electromagnetic forces to accelerate a propellant.

Electric space propulsion systems use energized atoms to generate thrust. The key element limiting the systems’ lifetime is the impact of the high-speed ion beams, which wear down the thruster’s graphite surfaces slightly more with each contact.

The carbon ricocheting particles from the graphite chamber walls can also re-deposit back onto the thruster surfaces when ion thrusters are ground tested in a closed chamber. This changes the measured performance characteristics of the thruster.

The University of Illinois at Urbana-Champaign researchers created a model to better understand the impacts of ion erosion on carbon surfaces as the first step towards foretelling its failure. They did this by using data from low-pressure chamber experiments and extensive simulations.

“We need an accurate assessment of the ion erosion rate on graphite to predict thruster life, but testing facilities have reported varying sputtering rates, leading to large uncertainties in predictions,” said Huy Tran, a Ph.D. student in the Department of Aerospace Engineering at UIUC.

The model we developed bridges the molecular dynamics simulation results to the experimental data. The next thing we want to look at is the evolving surface morphology over time as you put more and more xenon ions into the system. This is relevant to ion thrusters for deep space exploration.

Huck Beng Chew

It is challenging to build a large enough room to prevent ion-surface interactions at the chamber walls, according to Tran, making it impossible to reproduce the environment of space in a laboratory chamber.

There is disagreement regarding the type of graphite that is most resistant to the erosion process known as sputtering, despite the fact that graphite is commonly used for the accelerator grid and pole coverings in the thruster.

“The fundamental problem with testing an ion thruster in a chamber is that the thruster is continuously spitting out xenon ions that also impact with the chamber walls made out of graphite panels, but there are no chamber walls in space,” Tran said.

“When these xenon ions hit the graphite panels, they also sputter out carbon atoms that redeposit on the accelerator grids. So instead of the grid becoming thinner and thinner because of thruster erosion, some people have seen in experiments that the grids get thicker with time because the carbon is coming back from the chamber walls.”

The researchers and limitations gained insight into a crucial phenomenon and the simulation overcame uncertainties in the experimental data.

“Whether it is pyrolytic graphite on the grided ion optics, isotropic graphite on the pole covers, or poco graphite or anisotropic graphite on the chamber walls, our molecular dynamics simulations show that the sputtering rates and mechanisms are identical across all these different referenced structures,” said Huck Beng Chew, Tran’s adviser.

He said the sputtering process creates a unique carbon structure during the bombardment process.

“When the ions come and damage the surface, they transform the surface into an amorphous-like structure regardless of the initial carbon structure,” Chew said. “You end up with a sputtered surface with the same unique structural characteristics. This is one of the main findings that we have observed from our simulations.”

Chew said they even tried it with diamond. They obtained the same sputtering structure despite the substantially lower starting porosity and more rigid bond arrangement.

“The model we developed bridges the molecular dynamics simulation results to the experimental data,” Chew said. “The next thing we want to look at is the evolving surface morphology over time as you put more and more xenon ions into the system. This is relevant to ion thrusters for deep space exploration.”

The research is part of a NASA center known as the Joint Advanced Propulsion Institute which includes researchers at nine universities, including UIUC aerospace engineering faculties Chew, Debbie Levin, and Joshua Rovey who leads the Illinois team.

The simulations were performed using NCSA’s Delta, a supercomputing facility at Illinois.

The paper, “Surface morphology and carbon structure effects on sputtering: Bridging scales between molecular dynamics simulations and experiments,” is written by Huy Tran and Huck Beng Chew. It is published in the journal Carbon.