High-speed projectiles that puncture materials appear in many different ways, such as a gunshot piercing a first responder’s protective armor, a jellyfish stinging a swimmer, or a micrometeorite striking a satellite. It has been challenging to relate the microscopic characteristics of a promising new material to its actual behavior in practical circumstances, despite researchers’ ongoing efforts to find new materials that can better withstand these high-speed puncture events.

To address this issue, researchers at the National Institute of Standards and Technology (NIST) have designed a method that uses a high-intensity laser to blast microscale projectiles into a small sample at velocities that approach the speed of sound.

The system examines the energy transfer between the particle and the target sample at the microscopic level and then employs scaling techniques to forecast how well the material would withstand being punctured by more powerful energetic projectiles, such as bullets encountered in real-world scenarios. This innovative technique, which was published in the journal ACS Applied Materials & Interfaces, eliminates the need for extensive lab studies using larger projectiles and larger samples.

“When you’re investigating a new material for its protective applications, you don’t want to waste time, money and energy in scaling up your tests if the material doesn’t pan out. With our new method we can see earlier if it’s worth looking into a material for its protective properties,” said NIST chemist Katherine Evans.

During lab experiments, synthesizing small amounts of a new polymer e.g., a few milligrams from glassware the size of a coffee cup can be fairly routine. Scaling up to create kilograms of material to evaluate its puncture resistance presents a hurdle. Scaling up to adequate quantities for materials derived from novel synthetic polymers is frequently neither feasible or practical.

“The problem with ballistic tests is that you must take two steps when making new materials. You need to synthesize a new polymer that you think will be better, and then scale it up to kilogram size. That is a big jump. The biggest accomplishment of this work is that we surprisingly show that the micro-ballistic tests can be scaled and linked to real-world large-scale tests,” said NIST materials research engineer Christopher Soles.

This new paradigm gives us a new experimental tool to evaluate the hype of some of these graphene and other 2D materials that are predicted to have excellent ballistic properties. We have the potential to experimentally verify if these materials would outperform classic ballistic resistant materials like polycarbonates, even without scaling up the synthesis of novel 2D materials, which would be prohibitively costly.

Christopher Soles

The strong, all-carbon substance known as graphene, as well as a widely used compound for bulletproof glass, were among the materials evaluated by researchers using their method throughout the study.

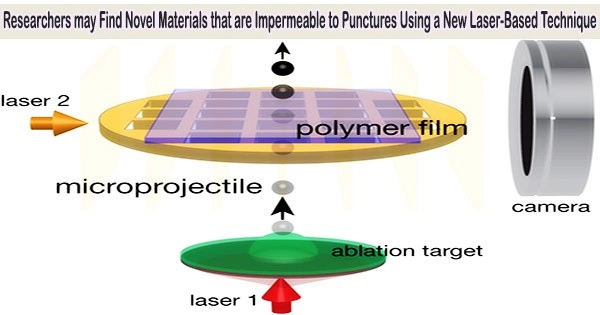

Laser-induced projectile impact testing, or LIPIT, is the name of the test. A silica or glass microprojectile is fired into a thin film of the target material using lasers. The laser generates a high-pressure wave through a process known as laser ablation that launches the microprojectile material in the direction of the sample.

The researchers first used the method to analyze a nanocomposite material known as polymer-grafted nanoparticle polymethacrylate (npPMA) composite. It is made up of silica nanoparticles, which have a variety of potential uses, including body armor. A video camera records the microprojectiles’ impacts as they are launched at the target material at speeds ranging from 100 to 400 meters per second by the laser.

Researchers combined the measurements they obtained on the npPMA with additional mathematical analysis and incorporated existing data on the material from the scientific literature in order to connect the outcomes of the microprojectile test to what would occur in larger-scale impacts.

They expanded their investigation to include a more generally accessible substance known as polycarbonate, which is frequently utilized as a bullet-resistant glass because npPMA is a novel material and difficult to manufacture.

Researchers were able to demonstrate that the puncture resistance of a material is related to the maximum stress a material can withstand before breaking, also known as the failure stress, utilizing a combination of the results from the literature, dimensional analysis, and LIPIT. The way pressure waves move through a material is often assumed to be related to ballistic performance, which is challenged by this.

In order to find the best materials for research, their new method can determine a material’s strength limits or how much stress and pressure it can withstand without first actually measuring these attributes. They were then able to investigate materials like graphene, which demonstrated that it can be used in many film layers in impact resistance applications just like high-performance polymers.

“This new paradigm gives us a new experimental tool to evaluate the hype of some of these graphene and other 2D materials that are predicted to have excellent ballistic properties. We have the potential to experimentally verify if these materials would outperform classic ballistic resistant materials like polycarbonates, even without scaling up the synthesis of novel 2D materials, which would be prohibitively costly,” said Soles.

Their approach might make it easier to find new materials for a variety of uses, including medicine delivery, improved animal bite protection, spacecraft protection, additive manufacturing, and spacecraft protection. Researchers are looking into developing needle-free injections in which a high-speed stream of fluid known as a liquid jet punctures the skin.

While many applications aim to avoid punctures, LIPIT can provide insights in this case on how to most effectively penetrate the skin using liquid jets as projectiles.

As for next steps, the researchers are pursuing several avenues. They intend to examine the various types and combinations as well as the extra innovative materials’ ballistic resistance. They will also vary the size of the microprojectiles and expand their velocity range.

NIST researchers are also looking to connect LIPIT’s experimental results to two types of simulations. One is finite element analysis (FEA), in which the object of interest is modeled as a group of simpler pieces that are interconnected. FEA is traditionally used to simulate the mechanical deformation of the entire sample.

Sometimes researchers can perform an FEA simulation faster than a lab experiment. However, in the end the simulation has to agree with experimental data on the actual material, said NIST materials science engineer Edwin Chan.

The second simulation approach is called molecular dynamics (MD). This type of simulation examines the behavior of materials like polymers at the molecular level on a much smaller scale. MD can investigate how polymer elements, like molecular chains, change after being struck by a projectile.

“Since we don’t have the ability to directly see what the polymer chains are doing, MD is insightful as it gives us a better idea on why certain polymers are better for impact resistance,” said Chan.

The researchers anticipate that this methodology will create a wide range of new opportunities for studying the behavior of materials.

“With this approach, we can ask, “What other things in the system can we change, or how can we improve a material for specific applications?” Instead of changing the composition of a material, you could change its geometry. Or you can study a material from nature and see how it behaves,” said Evans.