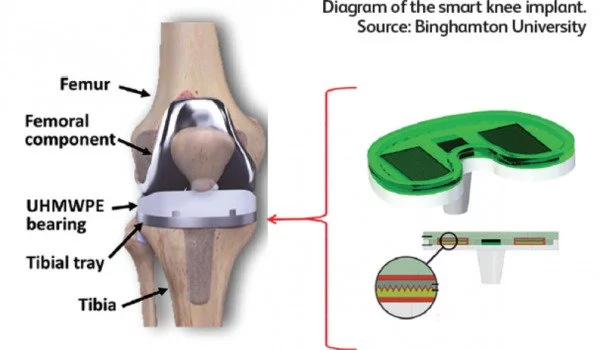

A cutting-edge design technique used to create components for the aerospace and automotive industries has been applied to the creation of custom medical devices. Researchers at the University of Birmingham used a technique called Generative Design, in collaboration with design software specialists Autodesk, the Manufacturing Technology Centre (The UK National Centre for Additive Manufacturing), and the University Hospitals Birmingham, to create a knee implant that can be used to treat osteoarthritis.

Progress for Additive Manufacturing has published a proof-of-concept paper describing the comprehensive workflow of detailed design and advanced manufacturing processes for a generatively designed patient-specific bone fixation device.

Generative design uses artificial intelligence (AI) and machine learning to design parts that can be manufactured to be absolutely optimal for their intended use. For an aircraft or a car, for example, this might be a component that is both lighter and stronger, leading to increased fuel efficiency and lower CO2 emissions. This study is the first known application of Generative Design to a biomedical implantable device.

This generative design approach not only increases the patient-specificity of bone fixations, but also serves as a novel, versatile framework in the design of load-bearing patient-specific implants for hips, shoulders, and maxillofacial surgeries.

Kanagalingam

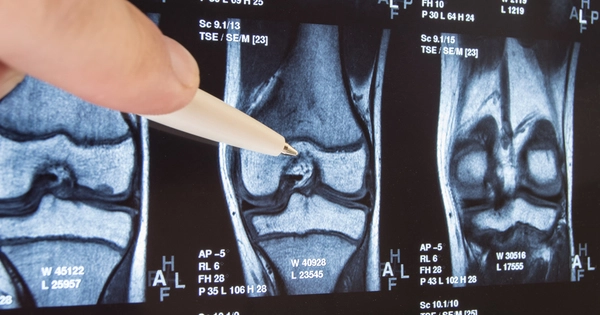

The ability to use this technology in medical applications has several advantages. For example, current knee implants for treating knee arthritis are only available in a few shapes and sizes. Although new 3D printing techniques are being used to create implants tailored to an individual patient’s shape, this does not account for surgical planning constraints, as well as the patient’s weight or activity levels. These are critical components for understanding how a patient’s anatomy and a knee implant will interact, as well as for implant design and post-surgical rehabilitation.

Because generative design allows for biomechanically specific implants, the implant can be tailored to the load it will bear. This also allows the finished product to be lighter, less noticeable, and less invasive, which means the patient will heal faster and will require less revision surgery.

The researchers outline how the design generated by Autodesk’s software can be manufactured and processed into a functional prototype, as well as how much of the process can be automated, in the new study.

Postgraduate and lead researcher, Mr. Sanjeevan Kanagalingam, of the University of Birmingham, said: “The ‘one-size-fits-all’ approach used in knee surgery to treat osteoarthritis can result in major complications, primarily due to over-engineered implant designs and therefore limits surgical adoption and patient outcomes. This AI-integrated design interface allows us to configure tailored surgical planning parameters and take personal biomechanical information into account, and synergistically combine it with the embedded manufacturing intelligence to model medical-grade titanium implants that are specific to each patient.”

Dr. Lauren Thomas-Seale, Principal Investigator and Senior Lecturer at the University of Birmingham, added: “The combination of the team’s academic, industrial, and clinical knowledge, as well as the vast design space provided by Generative Design, has resulted in implant designs that are unlike anything seen before. Taking into account the diversity of the project team, such an approach enabled the development of a design process that can account for the many differences between patients, such as the variation between male and female body mass.”

The devices will then be mechanically tested to see how much they bend and flex under load. If the project is successful, the team will proceed to clinical testing.

“This generative design approach not only increases the patient-specificity of bone fixations, but also serves as a novel, versatile framework in the design of load-bearing patient-specific implants for hips, shoulders, and maxillofacial surgeries,” Kanagalingam concluded.