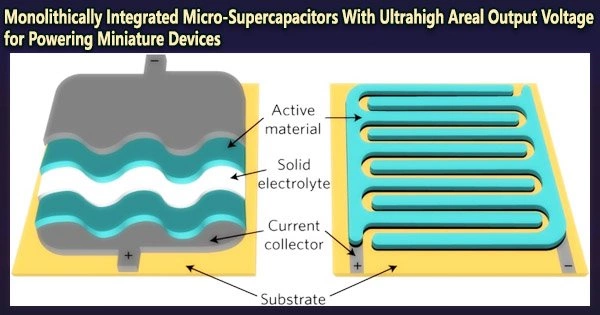

Compact monolithic integrated micro-supercapacitors (MIMSCs) with high systemic performance and cell number density will be required in the future to power miniaturized devices, however it is still difficult to scale up their manufacture. They face a number of obstacles in their way.

One of the most difficult problems to solve is precisely depositing electrolytes on tightly packed micro-supercapacitors (MSCs) while maintaining electrochemical isolation.

Furthermore, electrochemical performance may suffer dramatically during difficult microfabrication processes, and even then, it might be challenging to attain performance uniformity across a large number of individual cells.

To address these critical issues, Prof. Zhong-Shuai Wu and colleagues have developed an innovative and high-throughput strategy combining multi-step lithographic patterning, spray printing of MXene microelectrodes, and three-dimensional (3D) printing of gel electrolyte, for mass production of MIMSCs, simultaneously achieving superior cell number density and high systemic performance.

By combining 3D printing for precise electrolyte deposition with high-resolution micropatterning techniques for microelectrode deposition, the team was able to achieve the monolithic integration of electrochemically segregated micro-supercapacitors in close proximity.

This innovative microfabrication strategy marks a great advance as a new technological platform for monolithic micropower sources and will aid the applications where compact integration and high systemic performance is demanded from energy storage units.

Professor Zhong-Shuai Wu

First, benefiting from the high-resolution of lithographic patterning and uniqueness of MXene nanosheets, super-dense microelectrode-arrays were fabricated, and each individual MXene-based MSC exhibits an extremely small footprint of 1.8 mm2, high areal capacitance of 4.1 mF cm-2, high volumetric capacitance of 457 F cm-3, and stable performance at ultrahigh scan rate up to 500 V s-1.

They also created a straightforward, dependable, and high-throughput method for isolating individual electrochemical units. This required the logical design of a gel electrolyte ink that was compatible with an unique 3D printing technology. This allowed for the electrochemical isolation of adjacent microcells at a distance of only 600 m and exceptional performance uniformity.

Consequently, the researchers were able to obtain MIMSCs with a superior areal number density of 28 cells cm-2 (400 cells on 3.5×4.1 cm2), a record areal output voltage of 75.6 V cm-2, and an acceptable systemic volumetric energy density of 9.8 mWh cm-3, far exceeding those of the previously reported integrated MSCs.

The resulting MSCs demonstrated excellent performance consistency on a larger scale, and the MIMSCs demonstrate good capacitance retention of 92% after 4000 cycles at an extremely high output voltage of 162 V. This is attributable to the dependability and uniformity of each step in the microfabrication processes including lithography, spray printing, lift-off, and 3D printing.

“This innovative microfabrication strategy marks a great advance as a new technological platform for monolithic micropower sources and will aid the applications where compact integration and high systemic performance is demanded from energy storage units,” Wu says.