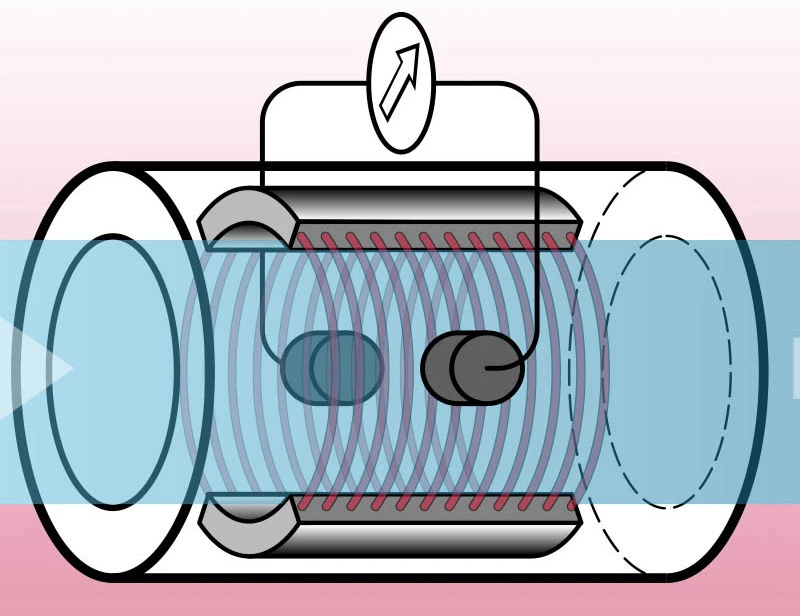

A magnetic flow meter (mag meter, electromagnetic flow meter) is a transducer that measures fluid flow by the voltage induced across the liquid by its flow through a magnetic field. It is a type of instrument used to measure the flow rate of a liquid or slurry in a pipe or conduit. It operates based on the principle of Faraday’s Law of electromagnetic induction.

A magnetic field is applied to the metering tube, which results in a potential difference proportional to the flow velocity perpendicular to the flux lines. The physical principle at work is electromagnetic induction. The magnetic flow meter requires a conducting fluid, for example, water that contains ions, and an electrical insulating pipe surface, for example, a rubber-lined steel tube.

If the magnetic field direction were constant, electrochemical and other effects at the electrodes would make the potential difference difficult to distinguish from the fluid flow induced potential difference. To show this in modern magnetic flowmeters, the magnetic field is constantly reversed, cancelling out the electrochemical potential difference, which does not change direction with the magnetic field. This however prevents the use of permanent magnets for magnetic flowmeters.

The basic components of a magnetic flow meter include a pipe or conduit through which the fluid flows, and a pair of electrodes that are mounted perpendicular to the flow direction. The electrodes are placed opposite to each other on the pipe walls and are in contact with the fluid. They are typically made of a corrosion-resistant material, such as stainless steel.

When the fluid flows through the pipe, it acts as a conductor and generates a voltage as it moves through a magnetic field created by the flow meter. This voltage is directly proportional to the velocity of the fluid and is measured by the electrodes. By knowing the cross-sectional area of the pipe, the magnetic flow meter can calculate the volumetric flow rate of the fluid.

The magnetic flow meter is particularly useful for measuring the flow of conductive fluids, such as water, acids, alkalis, slurries, and certain gases. It is not suitable for non-conductive fluids, such as oils or hydrocarbons.

Some advantages of magnetic flow meters include:

- High accuracy: Magnetic flow meters provide accurate measurements across a wide range of flow rates.

- No moving parts: They have no mechanical components that can wear out or get clogged, resulting in low maintenance requirements.

- Wide pipe size range: Magnetic flow meters are available in various sizes to accommodate different pipe diameters.

- Resistance to corrosion: Since the electrodes do not come into direct contact with the fluid, magnetic flow meters are resistant to corrosive substances.

However, there are a few limitations and considerations to keep in mind when using magnetic flow meters:

- Conductivity requirements: The fluid being measured must have a minimum conductivity to generate a measurable voltage.

- Pipe material: The pipe material must be non-magnetic to prevent interference with the magnetic field. Most commonly used pipe materials, such as stainless steel, PVC, and fiberglass, are compatible.

- Installation requirements: Proper installation is crucial for accurate measurements. Straight pipe runs, upstream and downstream disturbances, and proper grounding are necessary to ensure reliable performance.