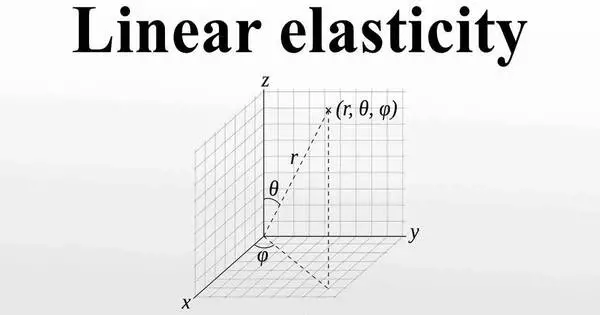

Linear elasticity is a branch of continuum mechanics that studies how solid materials respond to external loads. The material is assumed to behave linearly and elastically in linear elasticity, which means that the deformation is proportional to the applied load and that the material returns to its original shape after the load is removed.

Linear elasticity is a mathematical model that describes how solid objects deform and become internally stressed as a result of specific loading conditions. It is a branch of continuum mechanics and a simplified version of the more general nonlinear theory of elasticity.

Linear elasticity’s fundamental “linearizing” assumptions are: infinitesimal strains or “small” deformations (or strains), and linear relationships between stress and strain components. Furthermore, linear elasticity is only valid for stress states that do not result in yielding.

For many engineering materials and engineering design scenarios, these assumptions are reasonable. Linear elasticity is thus widely used in structural analysis and engineering design, often in conjunction with finite element analysis.

The stress-strain relationships are the fundamental equations of linear elasticity, which relate the stress, or force per unit area, applied to a material to the resulting strain, or deformation. These relationships are expressed in terms of a linear elastic modulus, which is a measure of the stiffness of the material.

A material’s linear elasticity can be determined using a simple test that involves placing a sample with its ends gripped in a tensile testing machine. The sample is loaded under controlled conditions, and the longitudinal stress is calculated as follows:

σ = F/A, where σ is the longitudinal stress, F is the applied force, and A is the sample’s cross-sectional area.

When a load is removed, materials with linear elasticity return to their initial state. Hooke’s law describes linear elastic behavior in tension tests as follows:

σ = Eε, where E is the elasticity modulus and ε is the true strain.

Linear elasticity is a material’s ability to deform under certain loading conditions without yielding. Linearly elastic materials obey Hooke’s law, which states that the stress-strain relationship is linear. Pipes made of flexible materials such as high-density polyethylene (HDPE), polyvinyl chloride (PVC), and polyethylene (PE) are used in trenchless installation techniques. These materials can withstand loads better than brittle pipe materials like concrete and steel.