1.1 Square Textiles Limited – Introduction

Garments sector is the largest export sector in Bangladesh. A huge amount of foreign currency earned from this sector. In recent decade Bangladeshi textile mills are facing some problem. As the cotton price is increasing many textile mills are switch off their business. They cant afford extra price of the cotton. On the other hand foreign order coming too low, because of the world financial crisis.

On the other hand Bangladeshi textile mills are facing heavy competition from the foreign textile mills. Our main competitors are China, India, Pakistan, Srilanka.

Square Textile Ltd.is one of the market leader of Bangladeshi Yearn market. They use modern machinarig for mnufacturing yearn. They can produce Cotton Mélange in their existing machine. The market demand of cotton melange is high in Bangladesh.

So, Square Textile Ltd. Try to reach in the Cotton Melange market.

1.2 Origin of the Study

As a prerequisite for the Bachelor of Business Administration Degree of the ASA University of Bangladesh, I was required to complete an Internship report in suitable business organization and submit a report on my findings. This report has been prepared through discussion with yearn buyer and with the clients. Field research, Annual report and website provided the helps to prepare the report. At the time of preparing the report, I had a great opportunity to have an in depth knowledge of all the yearn manufacturing & marketing activities theoretically by the “Market feasibility study of Cotton Mélange”.

This report is generating under the supervision of Mr.Habibur Rahman, lecturer, Bachelor of Business Administration, ASA University of Bangladesh.

1.3 Objectives of the Report:

The broad objective of this report is to provide an overview of market feasibility study of cotton mélange. The specific objectives of this report are:

- Collect information about cotton mélange market.

- To provide Company overview

- To provide market overview and analysis

- To reveal operational, management and marketing planning.

- Discuss all marketing practice.

1.4 METHOLODGY:

To prepare this report we have collected data from different published materials. Then we have conducted a secondary study. After that, we have prepared a questionnaire and took interview one of the executive serving in this Company. We also collect data from internet .This way we collected primary data. Thus, we have used both primary and secondary report to prepare this report.

1.5 SOURCES OF DATA

Data regarding the completion of this research will be collected from both primary and secondary sources.

Primary Sources:

A primary source is a document, speech, or other sort of evidence written, created or otherwise produced during the time under study. Primary sources offer an inside view of a particular event.

The sources are as follows Face-to-face conversation with the Executives and officers of Square textile Customers.

1.5.1 Secondary sources:

A secondary source is a secondhand account about people, events, topics or places that is based on what some other writer has experienced.

The secondary sources data and information are:

(i) Annual Report of Square Textile Limited

(ii) Website information.

http://wiki.answers.com

www.wikipedia.org

http://www.alibaba.com

2. Square Textiles Limited – Company Overview

2.1 COMPANY OVERVIEW

ABOUT COMPANY:

Square Textiles Ltd. started its journey by establishing the first unit in 1997. One year later, the second unit was established. Square Textile is a subsidiary company of Square Group .The Company was in-corporate as a public limited company in the year of 1994. The operation was started in 1997.It was enlisted in Dhaka Stock Exchange & Chittagong Stock Exchange in 2002. Within a very short time of span, the company achieved some significance success. Square Textile receives Oeko-Tex standard 100 and ISO-9002 certificates in the year 2000. Authorized capital of the company is Tk. 1000 million. It is paid- up capital is Tk. 811.72 million. 1782 employees are working in this organization. The business lines of Square Textiles Limited are manufacturing and marketing of yarn. The factory is located in Saradaganj, Kashimpur, Gazipur, Bangladesh. Its office is located at Uttara-7 Mascot plaza, Dhaka.

2.2 MISSION STATEMENT:

Our mission is the polestar of our vision for maximization of production of quality products and services strictly on ethical and moral standards at minimum costs to the society ensuring optimum benefits to the consumers, the shareholders and other stakeholders.

2.3. KEY PRODUCT / SERVICES:

As stated earlier the business line of the company is manufacturing and marketing of yarn. It manufactures:

• 100% Cotton Ring Span Yarn For Hosiery

• 100% Cotton OE Rotor Yarn for Hosiery

The final output is marketwise by Square Fashion Ltd. In Square Textile Limited two types of products are produced in two different units. These are as follows:

Unit 1: Combed and Carded Yarn from a count range of Ne.10 to Ne.80.

Unit 2: Combed Ring Yarn from a count range of Ne.20 to Ne.40. In Square Spinning Ltd. 100% Cotton Carded and Combed Yarn in the count range of Ne.16 to Ne.30 are produces. Finally in Square Fashion’s Ltd. Readymade Knit Apparels like T-shirts, Polo shirts, Tank tops, Pajamas, Sport wear, Under garments, Men’s & Ladies fashion wear , Kids wear etc

2.4 STRATEGIC GOALS & OBJECTIVES:

The company sets the following objectives for it to achieve:

• To strive hard to optimize profit through conduction of transparent business operations within the legal & Social framework with malice to none and justice for all in respective of gender disparity, caste, creed or religion or region.

- To Increase productivity

- To create more jobs with minimum investments

- To be competitive in the internal as well as external markets

- To maximize export earning with minimum imported in-puts

- To reduce the income gap between top & bottom categories of employees

- To promote corporate social responsibilities (CSR) amongst all

Thus the company focuses to pole-star its mission that fulfill the objective with emphasis on the quality of the product , process and services blended with good – governance that help build the image of the most enable corporate – citizenship at home and abroad . The company wants to produce such society friendly goods and services that go to satisfy the wants of all the relevant party without disturbing or damaging the socio- economic and ecological, balance of the mother earth and the process of human civilization leading to peaceful co-existence of all the leaving beings. The company always strives for top quality products at the least cost reaching the lowest rungs of the economic class of people in the country. The company values its obligation to the greater society as well as it strives to protect the interests of its shareholders and to ensure highest return and growth of their assets.

2.5 Market Exposure:

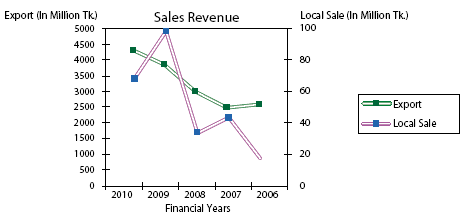

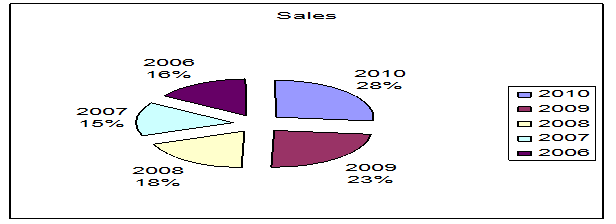

The Company’s marketing operations continued its emphasis on export sales over the years as depicted below:

2010 2009 2008 2007 2006

(a)Quantity Sold (Kg)

(i) Local Sales 416,387 561,347 165,247 221,514 112,706

(ii) Export Sales 19,628,509 22,625,699 15,491,421 13,371,187 14,001,403

(iii) Total Sales 20,044,896 23,187,046 15,656,668 13,592,701 14,114,109

(b) Sales Revenue (Tk):

(i) Local Sales 69,398,155 98,729,395 34,128,293 44,373,889 18,307,968

(ii) Export Sales 4,376,003,957 3,783,514,615 3,018,107,347 2,497,168,878 2,602,657,963

(iii) Total Sales 4,445,402,112 3,882,244,010 3,052,235,640 2,541,542,767 2,620,965,931

The above figures show while the local sales revenue decreased by 29.71% in 2010 over the previous year the export revenue rose by 15.65% during the year under review over 2009. The overall turnover also increased by 14.50% during 2010 over 2009.

2.6 Unit Selling Prices Attained:

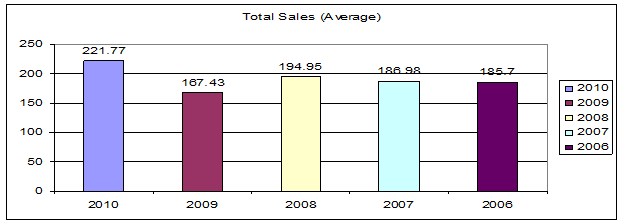

The selling Prices (Taka/ Kg) over the years varied substantially as shown below:

2010 2009 2008 2007 2006

Local Sales 166.67 175.88 206.53 200.32 162.44

Export Sales 222.94 167.22 194.82 186.76 185.88

Total Sales (Average) 221.77 167.43 194.95 186.98 185.70

The above indicate that while local selling price decreased by 5.24% during 2010 over 2009, export-selling price increased by 33.32% over the same period. This is primarily ascribable to the international situation and export demand. The overall average price increased by 32.45% during 2010 over 2009, as against raw material price increased by about 22.84% over the previous year.

2.7 Marketing working procedure of Square Textile

2.7.1 PI and L/C Handling Unit

Basic Work: PI and checking L/C.

Process: This total process is start from the customer-handling unit. The customer-handling unit manages the buyer’s and collect order from the buyer’s. Customer handling unit fill up the customer order form and send it to the PI unit. The customer-handling unit signs the order form and the management approves the rate of the product. After this step the PI and L/C unit start work.

PI unit check the rate of the product and cross check it one more time. After that the PI is making by the Square textile integrated software. For cross checking they also put the information on MS excel file. If the PI is ready, then PI unit send the PI to the buyer. On the other hand the PI and L/C unit also check the L/C. A L/C contains many clauses. A L/C may contain some risky clause, which may cause risk to the company. Sometimes clause is not clear to the beneficiary. These types of clause avoided by the L/C unit and as per management decision. At this situation, the L/C unit doesn’t approve this type of L/C.

PI related clause:

Document Clause

Financial Clause (Payment)

BTMA certificate (Cash incentive certificate)

Other’s condition

A good L/C must be fulfilling some condition. Those conditions are given bellow.

- L/C must be irrevocable.

- L/C must be opera table.

- L/C no. should be given.

- Date must be mentioned.

- The value must be containing.

- Beneficiary name must be given on L/C.

- Applicant name and address.

- Advising bank

- Applicant bank’s name& address

- Back to back or Export L/C number

- Date of the Export L/C number

If the L/C fulfills all the required condition, then the PI and L/C unit approve the L/C and give an entry to the software and manual Excel file. The PI and L/C unit work done by this step.

NOTES:

At site: At the time of bank acceptance, if the payment is clear.

Interest factor: It depends on the clause of PI. If the L/C contains a clause which indicates after the date of payment the buyer failed to pay the amount, then he has to pay a certain rate of interest.

LIBOR: London Internal Banking Offer Rate.

Discrepant Document: Discrepant document means, when the buyer failed to present a complete document or failed to prepare a proper document then it called discrepant document.

Handling Charge: The handling charge is making for handling the L/C by the bank. Handling charge is negotiable and it depends on bank for charging the handling charge.

2.7.2 DELIVERY UNIT

Basic Work: after PI unit work, the delivery unit starts their duties. PI unit send L/C and PI to the delivery unit. Delivery unit recheck the company name, date of L/C, shipment date, date of expired etc.

Delivery unit also collect the challan form and maintain it as the date & number.

Delivery unit main work is maintaining the delivery to the customer. By this way they also maintain the production. As per order basis the delivery unit controls the production. The date of delivery depends on the last date of shipment. Before this date the delivery unit makes the delivery. However, sometimes the delivery unit delivered the product as urgent basis as their customer requirement.

In the time of the delivery is made by different transport, they have to pay different tax and duties to the government like Mushok-11. Mushok-11 and others revenue paper also managed by the delivery unit.

Those steps do the delivery unit work. After that, the delivery unit sends all documents to the documentation unit. This step called pre-setup.

2.7.3 Documentation Unit

Documentation unit works for full set of document or final document for submit to the bank. By document submission, the documentation unit work is finished.

The documentation unit got document preparation order from the delivery unit/ customer-handling unit. Delivery unit provide L/C & PI for prepare the document. After getting the document preparation, order with L/C 7& PI documentation process start.

In pre-setup documentation unit, prepare some paper. Thus, papers are-

- Bill of Exchange

- Delivery Challan

- Invoice

- Packing List

- Certificate of Origin

- Beneficiary Certificate

- Mushok

- Truck Challan

- L/C Copy

After prepare thus paper the customer handling unit send thus papers (Without Certificate of Origin, Beneficiary certificate and mushok) to the buyer. The buyer signs it as an acceptance of those documents. This process called pre-setup.

The paper with signature of buyer when return, the documentation unit prepare this document as L/C requirement. Three set of total document is prepared for final documentation. One for the applicant Bank, one for the Beneficiary Bank & one for the keeping file for this document. This total process called post-setup.

Documentation unit also prepare EXP for the foreign buyer.

2.8 Processing of cotton

Cotton is the world’s most important natural fibers. In the year 2007, the global yield was 25 million tons from 35 million hectares cultivated in more than 50 countries.

There are five stages

- Cultivating and Harvesting

- Preparatory Processes

- Spinning

- Weaving

- Finishing

Cultivating and harvesting

Cotton is grown anywhere with long, hot dry summers with plenty of sunshine and low humidity. Indian cotton, gossypium arboreum, is finer but the staple is only suitable for hand processing. American cotton, gossypium hirsutum, produces the longer staple needed for machine production. Planting is from September to mid November and the crop is harvested between March and May. The cotton bolls are harvested by stripper harvesters and spindle pickers that remove the entire boll from the plant. The cotton boll is the seed pod of the cotton plant, attached to each of the thousands of seeds are fibers about 2.5 cm long.

2.8.1 Preparatory processes- preparation of yarn

- Ginning, bale making and transportation is done in the country of origin.

- Opening and cleaning

Cotton mills get the cotton shipped to them in large, 500 pound bales. When the cotton comes out of a bale, it is all packed together and still contains vegetable matter. The bale is broken open using a machine with large spikes. It is called an Opener.In order to fluff up the cotton and remove the vegetable matter, the cotton is sent through a picker, or similar machines. A picker looks similar to the carding machine and the cotton gin, but is slightly different. The cotton is fed into the machine and gets beaten with a beater bar, to loosen it up. It is fed through various rollers, which serve to remove the vegetable matter. The cotton, aided by fans, then collects on a screen and gets fed through more rollers till it emerges as a continuous soft fleecy sheet, known as a lap.

- Blending

Mixing & Scutching

Scutching refers to the process of cleaning cotton of its seeds and other impurities. A scutching machine for cotton was first invented in 1797, but didn’t get much attention until it was introduced in Manchester in 1808 or 1809. By 1816 it had been generally adopted. The scutching machne worked by passing the cotton through a pair of rollers, and then striking it with iron or steel bars called beaters. The beaters, which turn very quickly, strike the cotton hard and knock the seeds out. This process is done over a series of parallel bars so as to allow the seeds to fall through. At the same time, a breeze is blown across the bars, which carries the cotton into a cotton chamber.

- Carding

Carding: the fibers are separated and then assembled into a loose strand (sliver or tow) at the conclusion of this stage.

The cotton comes off of the picking machine in laps, and is then taken to carding machines. The carders line up the fibers nicely to make them easier to spin. The carding machine consists mainly of one big roller with smaller ones surrounding it. All of the rollers are covered in small teeth, and as the cotton progresses further on the teeth get finer (i.e. closer together). The cotton leaves the carding machine in the form of a sliver; a large rope of fibers.

Combing is optional, but is used to remove the shorter fibers, creating a stronger yarn.

- Drawing

The fibers are straightened several slivers are combined. Each sliver will have thin and thick spots, and by combining several slivers together, a more consistent size can be reached. Since combining several slivers produces a very thick rope of cotton fibers, directly after being combined the slivers are separated into ravings. These ravings (or slubbings) are then what are used in the spinning process.

Generally speaking, for machine processing, a roving is about the width of a pencil.

Drawing frame: Draws the strand out

Slubbing Frame: adds twist, and winds on to bobbins

Intermediate Frames: are used to repeat the slubbing process to produce a finer yarn.

2.8.2 Spinning- yarn manufacture

Spinning

The spinning machines take the roving thins it and twists it, creating yarn, which it winds onto a bobbin.

In mule, spinning the roving is pulled off a bobbin and fed through some rollers, which are feeding at several different speeds. This thins the roving at a consistent rate. If the roving was not a consistent size, then this step could cause a break in the yarn, or could jam the machine. The yarn is twisted through the spinning of the bobbin as the carriage moves out, and is rolled onto a cop as the carriage returns. Mule spinning produces a finer thread than the less skilled ring spinning.

The mule was an intermittent process, as the frame advanced and returned a distance of 5ft.It was the descendant of 1779 Crompton device. It produces a softer less twisted thread that was favoured for fines and for weft.

The ring was a descendant of the Arkwright water Frame 1769. It was a continuous process, the yard was coarser, had a greater twist and was stronger so was suited to be warp. Ring spinning is slow due to the distance the thread must pass around the ring, other methods have been introduced. These are collectively known as Break or Open-end spinning.

Checking

Folding and twisting

Plying done by pulling yarn from two or more bobbins and twisting it together, in the opposite direction that in which it was spun. Depending on the weight desired, the cotton may or may not be plied, and the number of strands twisted together varies.

Gassing

Gassing is the process of passing yarn, as distinct from fabric very rapidly through a series of Bunsen gas flames in a gassing frame, in order to burn off the projecting fibers and make the thread round and smooth and also brighter. Only the better qualities of yarn are gassed, such as that used for voiles, poplins, venetians, gabardines, many Egyptian qualities, etc. There is a loss of weight in gassing, which varies’ about 5 to 8 per cent., so that if a 2/60’s yarn is required 2/56’s would be used. The gassed yarn is darker in shade afterwards, but should not be scorched.

Measurements

Cotton Counts: The number of pieces of thread, 840 yards long needed to make up 1 lb weight. 10 count cotton means that 10×840 yd weighs 1 lb. This is coarser than 40 count cotton where 40×840 yards are needed. In the United Kingdom, Counts to 40s are coarse (Oldham Counts), 40 to 80s are medium counts and above 80 is a fine count. In the United States ones to 20s are coarse counts.

Hank: A length of 7 leas or 840 yards

Thread: A length of 54 in (the circumference of a warp beam)

Bundle: Usually 10 lb

Lea: A length of 80 threads or 120 yards

Denier: this is an alternative method. It is defined as a number that is equivalent to the weight in grams of 9000m of a single yarn. 15 denier is finer than 30 denier is.

Tex: is the weight in grams of 1 km of yarn.

The worsted hank is only 560 yd

2.8.4 Weaving-fabric manufacture

The weaving process uses a loom. The lengthways threads are known as the warp, and the crossway threads are known as the weft. The warp, which must be strong, needs to be presented to loom on a warp beam. The weft passes across the loom in a shuttle that carries the yarn on a pirn. The loom automatically changes these pirns. Thus, the yarn needs to be wrapped onto a beam and onto pirns before weaving can commence.

Winding

After being spun and plied, the cotton thread is taken to a warping room where the winding machine takes the required length of yarn and winds it onto wrappers bobbins

Warping or beaming

Racks of bobbins are set up to hold the thread while it is rolled onto the warp bar of a loom. Because the thread is fine, often three of these would be combined to get the desired thread count.

Sizing

Slasher sizing machine needed for strengthening the warp by adding starch to reduce breakage of the yarns.

Drawing in, Looming

The process of drawing each end of the warp separately through the dents of the reed and the eyes of the healds, in the order indicated by the draft.

Pirning (Processing the weft)

Pirn winding frame was used to transfer the weft from cheeses of yarn onto the pirns that would fit into the shuttle

Weaving

At this point, the thread is woven. Depending on the era, one person could manage anywhere from 3 to 100 machines. In the mid nineteenth century, four was the standard number. A skilled weaver in 1925 would run 6 Lancashire Looms. As time progressed, new mechanisms were added that stopped the loom any time something went wrong. The mechanisms checked for such things as a broken warp thread, broken weft thread, the shuttle going straight across, and if the shuttle was empty. Forty of these Northrop Looms or automatic looms could be operated by one skilled worker.

The three primary movements of a loom are shedding, picking, and beating-up.

Shedding: The operation of dividing the warp into two lines, so that the shuttle can pass between these lines. There are two general kinds of sheds-“open” and “closed.” Open Shed-The warp threads are moved when the pattern requires it-from one line to the other. Closed Shed-The warp threads are all placed level in one line after each pick.

Picking: The operation of projecting the shuttle from side to side of the loom through the division in the warp threads. This is done by the over pick or under pick motions. The over pick is suitable for quick-running looms, whereas the under pick is best for heavy or slow looms.

Beating-up: The third primary movement of the loom when making cloth, and is the action of the reed as it drives each pick of weft to the fell of the cloth.

The Lancashire Loom was the first semi-automatic loom. Jacquard looms and Dobby looms are looms that have sophisticated methods of shedding. They may be separate looms, or mechanisms added to a plain loom. A Northrop Loom was fully automatic and was mass-produced between 1909 and the mid 1960s. Modern looms run faster and do not use a shuttle: there are air jet looms, water jet looms and rapier looms.

Measurements

Ends and Picks: Picks refer to the west, ends refer to the warp. The coarseness of the cloth can be expressed as the number of picks and ends per quarter inch square, or per inch square. End’s is always written first. For example: Heavy domestics are made from coarse yarns, such as 10’s to 14’s warp and weft, and about 48 ends and 52 picks.

Associated job titles

- Piecer

- Scavenger

- Weaver

- Tackler

- Draw boy

- Pirner

2.8.5 Knitting- fabric manufacture

Knitting by machine is done in two different ways; warp and weft. Weft knitting (as seen in the pictures) is similar in method to hand knitting with stitches all connected to each other horizontally. Various weft machines can be configured to produce textiles from a single spool of yarn or multiple spools depending on the size of the machine cylinder (where the needles are bedded). In a warp knit, there are many pieces of yarn and there are vertical chains, zigzagged together by crossing the yarn. Cotton

Warp knits do not stretch as much as a weft knit, and it is run-resistant. A weft knit is not run-resistant, but stretches more. This is especially true if spools of Lycra are processed from separate spool containers and interwoven through the cylinder with cotton yarn, giving the finished product more flexibility and making it less prone to having a ‘baggy’ appearance. The average t-shirt is a weft knit.

2.8.6 Finishing- processing of textiles

The grey cloth, woven cotton fabric in its loom-state, not only contains impurities, including warp size, but requires further treatment in order to develop its full textile potential. Furthermore, it may receive considerable benefit by applying one or more finishing processes.

De-sizing

Depending on the sizes that have been used, the cloth may be steeped in a dilute acid and then rinsed, or enzymes may be used to break down the size.

Scouring

Scouring, is a chemical washing process carried out on cotton fabric to remove natural wax and non-fibrous impurities (eg the remains of seed fragments) from the fibers and any added soiling or dirt. Scouring is usually carried in iron vessels called kiers. The fabric is boiled in an alkali, which forms soap with free fatty acids (saponification). A kier is usually enclosed, so the solution of sodium hydroxide can be boiled under pressure, excluding oxygen which would degrade the cellulose in the fibers. If the appropriate reagents are used, scouring will also remove size from the fabric although desizing often precedes scouring and is considered a separate process known as fabric preparation. Preparation and scouring are prerequisites to most of the other finishing processes. At a stage even the most naturally white cotton fibers are yellowish, and bleaching, the next process, is required.

Bleaching

Bleaching improves whiteness by removing natural coloration and remaining trace impurities from the cotton; the degree of bleaching necessary is determined by the required whiteness and absorbency. Cotton being a vegetable fiber will be bleached using an oxidizing agent, such as dilute sodium hypochlorite or dilute hydrogen peroxide. If the fabric is to be dyed a deep shade, then lower levels of bleaching are acceptable, for example. However, for white bed sheeting’s and medical applications, the highest levels of whiteness and absorbency are essential.

Mercerizing

A further possibility is mercerizing during which the fabric is treated with caustic soda solution to cause swelling of the fibers. This results in improved luster, strength and dye affinity. Cotton is mercerized under tension, and all alkali must be washed out before the tension is released or shrinkage will take place. Mercerizing can take place directly on grey cloth, or after bleaching.

Many other chemical treatments may be applied to cotton fabrics to produce low flammability, crease resist and other special effects but four important non-chemical finishing treatments are:

Singeing

Singeing is designed to burn off the surface fibers from the fabric to produce smoothness. The fabric passes over brushes to raise the fibers, then passes over a plate heated by gas flames.

Raising

Another finishing process is rising. During rising, the fabric surface is treated with sharp teeth to lift the surface fibers, thereby imparting hairiness, softness and warmth, as in flannelette.

Calendaring

Calendaring is the third important mechanical process, in which the fabric is passed between heated rollers to generate smooth, polished or embossed effects depending on roller surface properties and relative speeds.

Shrinking (Sanforising)

Finally, mechanical shrinking (sometimes referred to as sanforizing), whereby the fabric is forced to shrink width and/or lengthwise, creates a fabric in which any residual tendency to shrink after subsequent laundering is minimal.

Dyeing

Finally, cotton is an absorbent fibers, which responds readily to coloration processes. Dyeing, for instance, is commonly carried out with an anionic direct dye by completely immersing the fabric (or yarn) in an aqueous dye bath according to a prescribed procedure. For improved fastness to washing, rubbing and light, other dyes such as vats and reactive are commonly used. These require chemistry that is more complex during processing and are thus more expensive to apply.

Printing

Printing, on the other hand, is the application of color in the form of a paste or ink to the surface of a fabric, in a predetermined pattern. It may be considered as localized dyeing. Printing designs on to already dyed fabric is also possible.

Economic, environmental and political consequences of cotton manufacture

The growth of cotton is divided into two segments i.e. organic and genetically modified. Cotton crop provides livelihood to millions of people but its production is becoming expensive because of high water consumption, use of expensive pesticides, insecticides and fertiliser. GM products aim to increase disease resistance and reduce the water required. The organic sector was worth $583 million. GM cotton, in 2007, occupied 43% of cotton growing areas.

The consumption of energy in form of water and electricity is relatively high, especially in processes like washing, de-sizing, bleaching, rinsing, dyeing, printing, coating and finishing. Processing is time consuming. The major portion of water in textile industry is used for wet processing of textile (70 per cent). Approximately 25 per cent of energy in the total textile production like fibers production, spinning, twisting, weaving, knitting, clothing manufacturing etc. is used in dyeing. About 34 per cent of energy is consumed in spinning, 23 per cent in weaving, 38 per cent in chemical wet processing and five per cent in miscellaneous processes. Power dominates consumption pattern in spinning and weaving, Processing of protein fibers

Wool

Wool comes from domesticated sheep. It forms two products, woollens and worsteds. The sheep has two sorts of wool and it in the inner coat that is used. This can be mixed with wool that has been recovered from rags. Shoddy is the term for recovered wool that is not matted, while mungo comes from felted wool. Extract is recovered chemically from mixed cotton/wool fabrics.

The fleece is cut in one piece from the sheep. This is then skirted to remove the soiled wool, and baled. It is graded into long wool where the fibers can be up to 15 in, but anything over 2.5 inches is suitable for combing into worsteds. Fibers less than that form short wool and are described as clothing or carding wool.

At the mill the wool is scoured in a detergent to remove grease (the yolk) and impurities. This is done mechanically in the opening machine. Vegetable matter can be removed chemically using sulphuric acid (carbonising). Washing uses a solution of soap and sodium carbonate. The wool is oiled before carding or combing.

Woollens: Use noils from the worsted combs, mango and shoddy and new short wool

Worsteds

- Combing: Oiled slivers are wound into laps, and placed in the circular comber. The worsted yarn gathers together to form a top. The shorter fibers or noils remain behind and are removed with a knife.

- Angora

Silk

The processes in silk production are similar to those of cotton but take account that reeled silk is a continuous fibers. The terms used are different.

Opening bales: Assorting skeins: where silk is sorted by color, size and quality, scouring: where the silk is washed in water of 40 degrees for 12 hours to remove the natural gum,

Drying: Either by steam heating or centrifuge, softening: by rubbing to remove any remaining hard spots.

Silk throwing (winding)

The skeins are placed on a reel in a frame with many others. The silk is wound onto spools or bobbins.

Doubling and twisting

The silk is far too fine to be woven, so now it is doubled and twisted to make the warp, known as organize and the weft, known as tram. In organize each single is given a few twists per inch (tpi), and combine with several other singles counter twisted hard at 10 to 14 tpi. In tram, the two singles are doubled with each other with a light twist, 3 to 6 tpi. Sewing thread is two tram threads, hard twisted, and machine-twist is made of three hard-twisted tram threads. Tram for the crepe process is twisted at up to 80 tpi to make it ‘kick up’.

Stretching

The thread is tested for consistent size. Any uneven thickness is stretched out. The resulting thread is reeled into containing 500 yd to 2500 yd. The skeins are about 50 in in loop length.

Dyeing:

The skeins are scoured again, and discoloration removed with a sulphur process. This weakens the silk. The skeins are now tinted or dyed. They are dried and rewound onto bobbins, spools and skeins. Looming and the weaving process on power looms is the same as with cotton.

Weaving:

The organize is now warped. This is a similar process to in cotton. Firstly, thirty threads or so are wound onto a warping reel, and then using the warping reels, the threads are beamed. A thick layer of paper is laid between each layer on the beam to stop entangling.

2.9 Mélange yarn

Mélange yarn is dyed before spinning. The yarn is produced from color printed tops or slivers. The color bands are short enough that each fiber has multiple colors. This results in a heathered effect after spinning.

Think of the individual hairs of a tabby cat. Individual hairs are banded so they contain both black and grey on the same hair. When the hair is brushed off the resulting effect is a heathered grey.

You can dye something with a similar appearance by choosing a yarn of blended cellulose and protein fibers, such as Trekking’s Pro Natura, which is a blend of wool and bamboo. These two fibers take dye at different rates. When dyed with an acid (protein) dye, the wool will take up more dye so it is darker than the bamboo fibers which take up less dye

2.10 Manufacturing process of Mélange yarn

Cotton Mélange yarn is spun from a number of cotton fibers with different colors. Mixing dyed and un-dyed colors in various ratio’s produces a variety of fancy yarns. This mixing of fibers (dyed and/or un-dyed), could be done in the Blow Room at the start of spinning preparation, or it could be done when putting fibers in the draw frames–this would be feeding different fibers into the drawing frames to create the cotton Mélange.

Mélange yarn is made of two or more different color fibers, which spun after fully mixing, therefore creating a unique mixed color effect.

2.11 Discussion of Different kind of Mélange Yearn

1. Cotton Mélange yarn

Quick Details

| Material: 100% Cotton | Yarn Type: Combed | Pattern: Dyed |

| Style: Mélange Yarn | Techniques: Ring Spun | Feature: Eco-Friendly, Anti-Pilling |

| Use: Knitting, Weaving | Twist: TPI 10 above | Evenness: average |

| Yarn Count: 16S | Place of Origin: China (Mainland) | Brand Name: Vico |

| Model Number: 16s, 21s, 32s, 40s | Mélange: grey |

Specifications

We can offer 16s-60s 100%cotton, Mélange yarn for knitting; circular knitting, weaving, auto Conner and ring spun waxed yarn

We can offer 16s-60s 100%cotton, Mélange yarn for knitting; circular knitting, weaving, auto Conner and ring spun waxed yarn

2. Cotton Mélange/heather yarns

Quick Details

| Product Type: Blended Yarn | Type: Cotton Blended Yarn | Style: Mélange Yarn |

| Use: Weaving |

Specifications

Cotton Mélange/heather yarns

Black cotton proportion in3%-30%, or following customers color standards

Ne10Ne40 Cotton Mélange yarns

Black cotton proportion in3%30%, or following customers color standards

For knitting or for weaving

Mélange (heather yarn) is formed of a plurality of major yarn bundles at least one of which is of a substantially different color from the remaining bundles.

3. Combed Cotton Mélange Yarn

Quick Details

| Material: 100% Cotton | Yarn Type: Combed | Style: Mélange Yarn |

| Use: Knitting | Use: Knitting | Place of Origin: Pakistan |

| Material: Cotton |

Specifications

100% Cotton Combed and Carded Mélange in various shades

100% Cotton Carded and Combed Mélange yarns in various shade as per your requirement.

Yarn is available for Socks knitting, Normal jersey knitting as well as Sweater Knitting in 2ply and 3ply.

4. 100 cotton Mélange yarn

Quick Details

| Material: 100% Cotton | Yarn Type: Combed | Pattern: Dyed |

| Style: Mélange Yarn | Techniques: Ring Spun | Feature: Eco-Friendly, Moisture-Absorbent |

| Twist: regulable | Evenness: standard | Yarn Count: 20s-60s |

| Strength: strong | Place of Origin: Zhejiang China (Mainland) | Brand Name: Huahong |

| material: 100% cotton |

Specifications

1. THE USE: KNITTINGFABRICS, SWEATERS, SOCKS

2.THE PAYMENT: T/T OR L/C

3.THE MOQ IS 5 KILOGRAMS

4.THE COUNTS: 20S-60

Our company is among the leading manufacturers of 100%cotton Mélange yarn and blended Mélange yarn and semi-worsted yarn.

The counts: 20-60s

The packing: carton 63*44*36cm (24cones)

Or weave bag

Or as clients’ requirement

Indicator: Dry rubbing fastness: 4-5

Wet rubbing fastness: 4-5

Washing fastness: 4-5

The quality and prompt shipment are guaranteed. The color engineer, the workshop manager has above 15 years experience .Good service would be insured.

5. Cotton Mélange Yarn for weaving or for knitting

Quick Details

| Product Type: Other Yarn | Material: cotton, polyester, wool etc. | Yarn Type: Combed |

| Pattern: Dyed | Techniques: Ring Spun | Feature: Eco-Friendly, Moisture-Absorbent |

| Use: Sewing, Hand Knitting, Knitting, Weaving, | Twist: flexible | Evenness: ok |

| Yarn Count: ne20~ne40 | Strength: flexible | Place of Origin: Shandong China (Mainland) |

| Brand Name: Teddy Bear | Model Number: UTSY-076 | Place of Origin: China |

| Model Number: UTSY-076 | Use: Knitting | Style: Mélange Yarn |

Specifications

*Composition: 100% combed or semi-combed cotton

*Count: Ne20s/1, Ne30s/1, Ne40s/1

*Color: 3%-8%Black or other colors

*Composition: 100% combed or semi-combed cotton

*Count: Ne20s/1, Ne30s/1, Ne40s/1

*Color: 3%-8%Black, or other colors according to customer’s request

*Use: For knitting or for weaving

*Packing: On cone in standard export packing.

- 6. 20ne-40ne top dyed mélange cotton yarn

Quick Details

| Material: 100% Cotton | Yarn Type: Combed | Pattern: Dyed | ||

| Style: Mélange Yarn | Techniques: Ring Spun | Feature: Eco-Friendly | ||

| Use: Knitting | Twist: 280-380 | Evenness: normal | ||

| Yarn Count: 20NE-40NE | Strength: normal | Place of Origin: Zhejiang China (Mainland) | ||

| Brand Name: RISING | Model Number: 201101M | Feature: Red | ||

| Brand Name: Rising | PASSED ISO9001: quality management system certi… | Bross color B1016: Bross color B20 | ||

| Place of Origin: Zhejiang, China | Material: 100% Cotton | Use: Knitting | ||

Specifications

Top dyed mélange yarn

high quality (same as bros and huafu’s)

Competitive prices (cheaper than bros and huafu’s)

Cotton mélange

We can make the color according to customer’s color card and also match bros or huafu’s color card with very competitive price.

All kinds of color available for different customer require

Good for clothes, sweater, socks, hat and shawl knitting and weaving,

Good for sofa fabric material and hand knitting yarn.

- 7. 60s top dyed mélange yarn with 100% Cotton

Quick Details

| Material: 100% Cotton | Yarn Type: Combed | Pattern: Other |

| Style: Mélange Yarn | Techniques: Ring Spun | Feature: Other |

| Use: Sewing, Hand Knitting, Knitting, Weaving | Twist: nice | Evenness: Good |

| Yarn Count: 60s | Strength: Nice | Place of Origin: Jiangsu China (Mainland) |

| Brand Name: Jinlan Brand | Model Number: Top Dyed |

Specifications

1100% cotton and so on

2 Many different colors

3 Soft

4 Mainly used for knitting machines

5 has gained the ISO-9000,ISO-9001

8. 26s Colorful 100% Mélange Cotton Yarn for Knitting

Quick Details

| Material: 100% Cotton | Yarn Type: Spun | Pattern: Dyed |

| Style: Mélange Yarn | Techniques: Ring Spun | Feature: Eco-Friendly, Recycled |

| Use: Knitting, Weaving | Twist: 70 | Evenness: nice |

| Yarn Count: Ne26s | Strength: 400 | Place of Origin: Hubei China (Mainland) |

| Brand Name: glory sunny | color: various |

Specifications

High quality bleach white 100% cotton yarn

soft and smooth hand feeling

favorable price

timely delivery

do as you require

Futures of the cotton yarn for weaving and knitting:

Material: 100% cotton

Count: 26s

Intensity: good

Color: various

Usage: making carpets, socks, gloves, towels, mops, curtains, cotton cords, garment accessories, etc

9. 32s Top Dyed 100% Cotton Mélange Yarn for knitting

Quick Details

| Material: 100% Cotton | Yarn Type: Spun | Pattern: Dyed |

| Style: Mélange Yarn | Techniques: Ring Spun | Feature: Eco-Friendly, Anti-Bacteria, Moisture-… |

| Use: Hand Knitting, Knitting | Twist: 350 | Evenness: 5% |

| Yarn Count: 32s | Strength: 675 | Place of Origin: Yunnan China (Mainland) |

| Brand Name: Xin Huang | Model Number: SL033~SL048 | color: any color |

Specifications

1.100% cotton and so on

2.any color with client’s requirement

3.mainly used for knitting

1).Product Name:

32s 100% cotton dyed mélange yarn

2).Quality Certificate:

Oeko-Tex Standard 100

3).Count:

by customers’ request

4).Material:

100%combed cotton, 100% Egypt cotton, 100% long-staple cotton in Xinjiang

5).Feature:

Soft hand feeling, less hairy, good yarn evenness, strong yarn strength

6).Usage:

Yarn for circular, weaving and flat knitting (for jersey and sweater etc.)

Yarn for woven

Yarn for hand knitting or crochet

10. Mélange yarn

Quick Details

| Material: 100% Cotton | Yarn Type: Spun | Pattern: Dyed | ||

| Style: Mélange Yarn | Techniques: Ring Spun | Feature: Eco-Friendly, Recycled, Anti-Bacteria, | ||

| Use: Hand Knitting, Knitting | ||||

Specifications

100% cotton gray mélange yarn, good for knitting

Mélange yarn includes gray mélange yarn and color mélange yarn. It is spun by two different color fiber.

We can supply different materials mélange yarn, cotton, viscose, polyester, and this blended yarn.

The yarn is Automatic Winding.

11. 100% cotton mélange yarn

Quick Details

| Material: 100% Cotton | Yarn Type: Combed | Pattern: Dyed |

| Style: Mélange Yarn | Techniques: Ring Spun | Feature: Eco-Friendly |

| Use: Hand Knitting, Knitting, Weaving | Twist: regulable | Evenness: standard |

| Yarn Count: 20s-60s | Strength: strong | Place of Origin: Zhejiang China (Mainland) |

| Brand Name: Huahong | use: knitwear/sweater |

Specifications

1. The counts: 20s -60s

2.The payment: L/C or T/T

3.The MOQ: 5 kilogram/kilograms

4.The production capacity: 20 tons per day

Or weave bag

Or as clients’ requirement

Indicator: Dry rubbing fastness:4-5

Wet rubbing fastness:4-5

Washing fastness: 4-5

4.0 Conclosion

Garments sector is the largest export sector in Bangladesh. A huge amount of foreign currency earned from this sector. In recent decate Bangladeshi textil mills are facing some problem. As the cotton price is increasig many textle mills are switch off their business. They cant afford extra price of the cotton. On the other hand foreign order coming too low, because of the world financial crisis.

Square Textile Ltd.is one of the market leader of Bangladeshi Yearn market. They use modern machinarig for mnufacturing yearn. They can produce Cotton Mélange in their existing machine. The market demand of cotton melange is high in Bangladesh.

So, Square Textile Ltd. Try to reach in the Cotton Melange market.

4.1 Recommendtion

Before drawing the end, I would like to offer the following suggestions for bringing improvements of Square Textile Limited.

They should follow “Radical Marketing” for keep their brand name in higher position.

Marketing department of Square textile ltd needed more skill people for making their operation smooth.

Cotton Mélange as a new product, it needed more market testing and provide sample to the buyer.

As a new product, Square textile should provide knowledge about the product to the customer.

Quality of the product should not be considered for making good profit.