Company profile:

Masco Industries Limited is totally commited to its products and customers which has helped it grow from a knit fabric manufacturer to a composite and garment manufacturer. Masco Industries Limited is a pioneer in introducing European technology in knit fabric manufacturing in this country.

They started their journey at June 2001. Now Masco have one knitting factory, one dyeing factory and two garment manufacturing units with capacity about (15 millions doz. of T-Shirt, Polo Shirts, Shorts of all designs per day, they are in a position to serve the ultimate users to their satisfaction. Masco may not be so big if the capacities are considered but our commitment to quality and adaptability to the ever-changing customer demand is their strength.

COMPANY DIRECTORY

Management

- Group Chairman : M. A. SABUR

- Managing Director : AHMED ARIF BILLAH

- Director : MS. FAHIMA AKHTER

- Director : MS. FARHANA AKHTER

- Director (Operations) : ATM MAHBUBUL ALAM CHOWDHURY.

As a composite project, the enterprises have been organized in the following manner:

- Masco Group : Corporate Head Office

- Masco Knitting Unit : Fabric Knitting – Project in operation.

- Masco Dyeing Unit : Fabric Dyeing – Projects in operation.

- Masco Washing Unit : Fabric washing – Projects in operation

- Masco Garments Unit-1 : Garments Manufacturing

-Project in operation

- Masco Garments Unit-2 : Garments Manufacturing

-Project in operation

- MPL Wear Ltd : Garments Manufacturing

-Project in operation

- Mascotex Limited : Garments Manufacturing

-Project in operation

- Masco Embroidery Uni : Embroidery Unit

-Projects in Operation.

- Masco Yarn Dyeing Unit : Yarn Dyeing

-Project is under implementation

- Masco Printing Unit : Printing Unit

-Project in operation

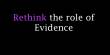

Location

The head office is located at a prestigious business area called Uttara which is near to the Dhaka international Airport. 9th & 10th processes of the Yarn Dyeing & Flat Bed All over Printing unit are located at Narsingdi and the projects are under implementation. Others processes (2nd, 3rd, 4th, 5th & 6th) are located at Gazipura, Tongi which is only 7 kms North from Dhaka International Airport.

Head Office : Masco Center

House # 06, Road # 01, Sector # 03

Jashimuddin Avenue, Uttara.

Dhaka – 1230, Bangladesh.

Factory : 221-223 Khartail, Shataish Road

Tongi, Gazipur- 1712, Bangladesh

Phone: 88-02-9813362, 9810790-91, 9815041-42

Fax : 88-02-9810790

Nature of Project : 100% Export Oriented Composite Knit Garments Industry

Year of Establishment : June 2001

Quality Certification : ISO 9002

Oeko-Tex

Walt Disney

Control Union Certifications

Present Buyers:

- New Wave (Sweden)

- Umbro (UK)

- Aldi (Germany)

Zara (Spain) - Stradivarius (Spain)

- Bershka (Spain)

- Big Star (Poland)

TK International (Germany) - Lonsdale (UK)

- Tchibo(German)

- H & M

- C & A

- KIK

| Countries of Exports: | A) Germany C) Sweden E) Italy G) United Kingdom I) Poland K) Austria M) Belgium | B) Spain D) The Netherlands F) France H) Norway J) Finland L) Denmark |

| Countries of Imports: | A) Hong Kong B) China C) Korea D) Thailand E) Taiwan | |

Factory is totally equipped and conditioned to cover requirements for International and National Social Compliance, some features of which are as follows:

Stair cases : 2 Six feet wide spacious stair cases with one emergency evacuation

Wash room & toilet : 1: 25 Persons

“Exit” signs : Exit signs are marked clearly for emergency evacuation

Medical facility : One M.B.B.S doctor caters to the health needs of the workers

Emergency Medical : Trained team of staff & workers to take initiatives in case of emergencies

First Aid : Adequate First Aid Boxes/Kits are placed at different places

Emergency Tele No. : Lists containing emergency Telephone numbers such as Fire Brigade, Hospitals & Police Stations hanged for emergency needs

Fire Extinguisher : Fire extinguishers are placed in a very balanced manner

Fire Drill : Weekly fire drills are initiated

Emergency Light : Emergency lights are there to use in case of power failure

Alternative Power : 316 KVA U.S. made Power Generator (Cummins) is used in Garments unit as source for instant supply of sufficient power for smooth operation during the power cut from national power supply grid. The Dyeing Factory has a 500 KVA Gas Generator for continuous supply of electricity in Dying and Finishing unit.

Work Environment : An excellent work environment exists in the Factory. Adequate ventilation & bright electric light is provided. Music & public address systems are always there inside the Factory.

Child labors : No child labor is allowed to work as per company policy

Day Care Center : The Company runs a day care center for workers children

Weekly Holiday : The Company follows the 7th day rest policy for each and every worker

CHAPTER-02

HUMAN RESOURCE MANAGEMENT

MANPOWER MANAGEMENT

Management System:

The company has skilled administration, management and marketing team guided by proficient, dexterous & experienced leaders of offer right solution for the consumers with the right eminence & with the shortest lead-time for the export market in Bangladesh.

The best use of continuous development of human resources by providing them International standard equal opportunity is the keys for achieving comprehensive competence in all level of the organizational hierarchy.

ORGANOGRAM OF DYEING SECTION

ORGANOGRAM OF KNITTING SECTION

ORGANOGRAM OF KNITTING SECTION

ORGANOGRAM OF UTILITY SECTION

Manpower in Dyeing Section:

| Section | Strength | ||

| Staff | worker | Total | |

| Administration | 14 | 19 | 33 |

| Accounts | 3 | 0 | 3 |

| Knitting | 24 | 94 | 118 |

| Dyeing | 12 | 58 | 70 |

| Finishing | 9 | 70 | 79 |

| Maintenance | 14 | 21 | 35 |

| Quality | 16 | 13 | 29 |

| Laboratory | 9 | 2 | 11 |

| Batch | 3 | 25 | 28 |

| Sample | 4 | 0 | 4 |

| Wash | 7 | 7 | 14 |

| Chemical store | 4 | 5 | 9 |

| Security | 7 | 15 | 22 |

| Yarn dyeing | 6 | 8 | 14 |

| Mudafa printing | 4 | 3 | 7 |

| G. Total | 141 | 365 | 506 |

Responsibilities of Production Manager:

- To plan the production schedule with capacity & volume of order.

- To observe dyeing finishing.

- To arrange necessary raw materials for production

- To follow the production and to give solution to the production problems

- To supervise senior production officer & production officer.

- To rectify any kinds of problems during dyeing.

- To follow up the instruction of managing director and executive director as well.

Responsibility of production officer:

- To give dyeing program slip.

- To check recipe.

- T o match production sample with target shade.

- Monitoring Batch preparation & pH checking.

- To collect production sample for sample matching next production.

- To observe dyed fabric during finishing running also after finishing.

- To find out dyeing & fabric fault as early as possible.

- To recover the finished fabric this is rejected from quality department.

- To discuss with DGM about overall production if necessary.

- To sign the store requisition and delivery shipment in the absence DGM.

- Control of supervisor, operator, asstt. operator & helper of dyeing floor.

- To register each batch dyeing condition.

- To check daily production report.

- To check water level in dyeing stage.

- To maintain connection with finishing & quality control department.

- To maintain connection with maintenance department etc.

- To recover the finished fabric this is rejected from quality department.

- To recover the finished fabric this is rejected from quality department.

- To recover the finished fabric this is rejected from quality department.

Job description of Production officer:

Job title : Production officer and senior production officer.

Report to : Production Manager.

Purpose : To control shift according to the plan made by production Manager.

Area : dyeing section (major), Batching and Finishing section (minor).

Job description of production officer:

Report To : Senior production officer.

Job Summary : To plan execute & follows up the production activities & control the quality production with related activities

Duties & Responsibilities:

- Overall supervision of dyeing, finishing production.

- Batch preparation & pH check.

- Dyes & chemical requisition issue & check.

- Write fabrics loading time from m/c.

- Program making sample checking color management.

- Control the supervisors, operator, and helpers of dyeing m/c.

- And also any other work as & when required by the management.

Job description of senior production Officer:

Report to : P.M (production).

Job Summary : To plan execute& follow up the production with related activities.

Duties & Responsibilities:

- Overall supervision of the dyeing finishing production.

- Checks the different log books of different areas report to management.

- Checks the sensitive parameters of deferent machines for smooth dyeing.

- Maintain of machine & equipment any other work & when required by the management.

- Control the supervisor operator ass, operator, helpers of dyeing machine.

Remarks:

The Manpower management system is well arranged in Masco Industries Ltd . Every officer & stuffs are responsible to their duty. But there are only seven textile engineers in the industry. It is sufficient for bulk production. The efficiency of the worker should be increased for, more quality production.

CHAPTER-3

RAW MATERIALS

Following are the different qualities of yarn that are used for knitting process:

SL.No | Yarn composition | Count |

1. | 100% Cotton | 20/1 Ne |

24/1 Ne | ||

26/1 Ne | ||

28/1 Ne | ||

30/1 Ne | ||

32/1 Ne | ||

34/1 Ne | ||

40/1 Ne | ||

60/1 Ne | ||

2. | Lycra | 20 Denier |

40 Denier | ||

3.

| Grey Mellange(95% Cotton 15% Viscose) | 26/1 Ne |

28/1 Ne | ||

30/1 Ne | ||

34/1 Ne | ||

40/1 Ne | ||

4. | Polyester | 75 Denier |

150 Denier | ||

5. | CVC(60%Cotton 40% Polyester) | 20/1 Ne |

24/1 Ne | ||

26/1 Ne | ||

28/1 Ne | ||

30/1 Ne | ||

32/1 Ne | ||

34/1 Ne | ||

40/1 Ne | ||

6. | Dyed Yarn | 20/1 Ne |

24/1 Ne | ||

26/1 Ne | ||

28/1 Ne | ||

30/1 Ne | ||

32/1 Ne | ||

34/1 Ne | ||

40/1 Ne | ||

60/1 Ne |

PRODUCT VARIATION

● Name of product mix :

The product, which are available in knit dyeing floor are given below:

→ Single jersey / Single jersey with lycra.

→ Polo pique, Lacost (Single / Double).

→ Rib – (1×1), (2×2),

→ Lycra Rib, Drop needle fabric.

→ Inter lock.

→ Grey mélange.

→ Stripe (S/J, rib, interlock, grey mélange)

For cotton / Blend / CVC fabric:-

→ S/J without lycra –

Fabric G.S.M | Yarn Count |

110 – 120 | 40 S – 36 S |

120 – 130 | 36 S – 32 S |

130 – 140 | 32 S – 28 S |

140 – 150 | 28 S |

150 – 160 | 26 S |

170 – 210 | 24 S |

→ Rib without lycra –

Fabric G.S.M | Yarn Count |

180 – 190 | 36 S – 32 S |

190 – 200 | 30 S |

200 – 215 | 28 S |

215 – 230 | 26 S |

230 – 250 | 24 S |

250 – 300 | 24 S |

→ Interlock without lycra –

Fabric G.S.M | Yarn Count |

200 – 220 | 34 S |

220 – 230 | 32 S |

230 – 250 | 30 S |

250 – 300 | 26 S |

→ Lacost ( S/L, D/L ) without lycra –

Fabric G.S.M | Yarn Count |

180 – 190 | 30 S |

190 – 210 | 28 S |

210 – 230 | 26 S |

230 – 250 | 26 S |

→ 40D Lycra Rib –

Fabric G.S.M | Yarn Count |

230 – 240 | 32 S |

240 – 250 | 30 S |

250 – 280 | 26 S |

280 – 300 | 24 S |

→ 40D Lycra S/J –

Fabric G.S.M | Yarn Count |

180 – 190 | 34 S |

190 – 210 | 32 S |

210 – 220 | 30 S |

220 – 240 | 28 S |

240 – 250 | 26 S |

Source of yarn for knitting:

- Creora, Korea

- Texlon, Korea

- Techno

- Badsha Winsome

- Nahar spinning Asia

- AML Malek spinning

- Daicoung PTHM for Slub

- Square textile Amber spinning

- Prime S.Pur

- Zaber Rswm

- Mahima Maral Overseas

- Paradise spinning Techno (poly tex)

- Ibrahim Bengal textile

- N.Z Textile Shameem

- GPI textile Asian textile

- Kamal Hazrat Amanat Shah

- Sunson textile NRG

Price of Cotton yarn:

Yarn Count | Combed Yarn | Carded Yarn |

40/1 | 3.65 $/Kg | 2.65-2.7 $/Kg |

34/1 | 3.00 $/Kg | 2.5-2.6 $/Kg |

32/1 | 2.90 $/Kg | 2.30 $/Kg |

30/1 | 2.70 $/Kg | 2.30 $/Kg |

28/1 | 2.70 $/Kg | 2.25 $/Kg |

26/1 | 2.65 $/kg | 2.25 $/Kg |

24/1 | 2.60 $/Kg | 2.25 $/Kg |

22/1 | 2.55 $/Kg | 2.20 $/Kg |

20/1 | 2.50 $/Kg | 2.15-2.2 $/Kg |

FABRIC TYPES:

1) Single Jersey

- Single jersey (Plain)

- Single lacoste

- Double lacoste

- Polo pique

- Fleece fabric

2) Double jersey

- Rib fabric

- 1×1 Rib

- 2×1 Rib

- 2×2 Rib

- Lycra Rib

b. Interlock Fabric

- Plain interlock

3) Back Brush.

4) Collar and Cuff

- Plain Collar or Solid collar

- Stripe Collar.

Dyes and chemicals used by Masco industries Ltd.

Name of the Dyes/Chemicals | Supplier Name | S/R | Name of the Chemicals | Supplier Name | |

| Albafix ECO | Huntsman | 43. | Drimarine Red CL5B | Clariant | |

| Albafix FRD | Huntsman | 44. | Drimarine Blue CLBR | Clariant | |

| Albafluid C | Huntsman | 45. | Drimarine Blue HFRL | Clariant | |

| Carite CBB | Huntsman | 46. | Darimagen E2R Liq. | Clariant | |

| Eriopon R | Huntsman | 47. | Bactasol SAP Liq. | Clariant | |

| Invatex CRA | Huntsman | 48. | Ladiquest 1097 Liq. | Clariant | |

| Novacron FN-2BL | Huntsman | 49. | Asntimusol HTS Liq. | Clariant | |

| Uvitex BHV Liq. | Huntsman | 50. | Sirrix 2UD Liq. | Clariant | |

| Clarite BB | Huntsman | 51. | Drimarine Turquoise CLB | Clariant | |

| Novacron Blue FN-R | Huntsman | 52. | Drimarine Yellow HF3GL | Clariant | |

| Novacron Brilliant red FN3 | Huntsman | 53. | Drimarine Yellow CL2R | Clariant | |

| Novacron Ocean S-R | Huntsman | 54. | Oleophobol CO | Huntsman | |

| Novacron W-B | Huntsman | 55. | Matexil NSB | CRODA | |

| Novacron Ruby S-3B | Huntsman | 56. | Matexil ADW | CRODA | |

| Novacron Super Black G | Huntsman | 57. | Synozol Red HB | KISCO | |

| Novacron Yellow FN-2R | Huntsman | 58. | Synozol Yellow HB | KISCO | |

| Novacron Yellow S- 3R | Huntsman | 59. | Synozol Navy Blue HB | KISCO | |

| Univadine TOP | Huntsman | 60. | Synozol Deep Red HB | KISCO | |

| Cepamine CWS | Huntsman | 61. | Synowhite 4BK | KISCO | |

| Uvitex 2B Conc | Huntsman | 62. | Kemifix Yellow FRL | LOXIM | |

| Primafast 100 | Zenencore | 63. | Kemifix Blue F2R | LOXIM | |

| Catalase T100 | Zenencore | 64. | Kemifix Black GR | LOXIM | |

| Imacozine Red E-3BF | Impocolor | 65. | Kemifix Yellow F4G | LOXIM | |

| Imcozine Yellow E-3R | Impocolor | 66. | Kemifix Red 3BS | LOXIM | |

| Imcozine Turquoise V-G | Impocolor | 67. | Kemifix Orange 2RL | LOXIM | |

| Imcozine V-4GL | Impocolor | 68. | Kemazol Black B | LOXIM | |

| Imcozine Golden Yellow VR | Impocolor | 69. | Drimarine Blue CLBR | Clariant | |

| Imcozine Red V-F3B | Impocolor | 70. | Drimarine Vilot K2R | Clariant | |

| Levafix Fast Red CA | Dystar | 71. | Drimarine Blue K2RL | Clariant | |

| Remazol Yellow RR | Dystar | 72. | Novacron Dark Blue WR | Huntsman | |

| Remazol Brilliant Blue BB | Dystar | 73. | Navacron Blue SGL | Huntsman | |

| Remazol Brilliant Blue Rspl | Dystar | 74. | Amron Amber HR2D | AMTEX | |

| Remazol Red RR | Dystar | 75. | Amron Yellow HR2D | AMTEX | |

| Remazol Brilliant Yellow 3G | Dystar | 76. | Amron Red HR2D | AMTEX | |

| Remazol Blue RR | Dystar | 77. | Amron Blue HR2D | AMTEX | |

| Levafix Blue CA | Dystar | 78. | Amron Red HR6BF | AMTEX | |

| Remazol Ultra Red RGB | Dystar | 79. | Amron Navy HR2D | AMTEX | |

| Levafix Amber CA | Dystar | 80. | Amron Yellow 3BXF | AMTEX | |

| Remazol GoldenYellow RGB | Dystar | 81. | Amron Red 3BXF | AMTEX | |

| Remazol Orange RR | Dystar | 82. | Imerol PCLF | Clariant | |

| Remazol Navy RGB | Dystar | 83. | Anticrease 200 | BUMPO | |

| Remazol Blue RGB | Dystar | 84. | Stagen B | BUMPO | |

| Invatex AC | Huntsman | 93. | Elbezol Yellow 3RS | Elbe Int. | |

| Imcozine Navy Blue E2G | Impocolor | 94. | Elbezol Navy BF | Elbe Int. | |

| Corazol Red RD | Chemi Enterp | 95. | Acetic Acid | Jubilant | |

| Corazol Yellow RD | Chemi Enterp | 96. | Soda Ash | ICI | |

| Ambron Black HR2D | AMTEX | 97. | Glauber’s Salt | JTAC | |

| Supra Red S2B | WIDTEX | 98. | Hydrosulphite | BASF | |

| Elbazol Black WNN | Elbe Int. | 99. | Caustic Soda | ASM Enterp. | |

| Elbezol Red 3BSN | Elbe Int. | 100 | Hydrogen Peroxide | HP | |

CHAPTER- 4

KNITTING SECTION

Layout of Knitting Section:

Knitting Section:

Knitting section is divided in four sections.

- Inspection section

- Flat knitting section

- Circular knitting section

- Store section

1. Cloth inspection section:

In cloth inspection section two machines are available. Specification of those machines is given below:

Type : Cloth Inspection Machine

Manufacture : UZU Fabric Inspection

Country : Turkey

Model No. : N/A

2. Flat knitting section:

Generally collar cuff of knitted garments is produced in this section. In this section there are 06 flat knitting machines. All of them are same type and also have same specification all machines is given below:

Type : Fully Automatic Flat

Manufacture name : Around Star

Country : China

Model No. :AS-318J

Type : Fully Automatic Flat

Manufacture name : Matsuya

Country : Japan

Model No. :M-100

3. Circular Knitting Section:

This section contains 13 circular knitting machines. Circular knitting machines are of different types, made by different manufacture and also have different specification. In this section body fabric for knitted garments is produced. The different specifications of different machines are given one after another.

Process flow chart of knitting:

Yarn in cone form

Feeding the yarn cone in the creel

Feeding the yarn in the feeder via trip-tape positive feeding arrangement and

Tension devices

Knitting

Withdraw the rolled fabric and weighting

Inspection

Numbering

| M/C no | Machine type | Brand Name | Model No | Origin | Manuf. Date | M/C Dia | M/C Gauge | No of Needle | No of Feeder |

| 1 | Single Jersey | Top Knit | KM-3WV4T | Korea | 2009/9 | 26″ | 24 | 78 | |

| 2 | Single Jersey | Top Knit | KM-3SF | Korea | 2009/9 | 30″ | 24 | 90 | |

| 3 | Single Jersey | Top Knit | KM-3WV4T | Korea | 2009/9 | 30″ | 24 | 90 | |

| 4 | Single Jersey | Top Knit | KM-3WV4T | Korea | 2009/9 | 30″ | 24 | 90 | |

| 5 | Single Jersey | Top Knit | KM-3WV4T | Korea | 2009/9 | 32″ | 24 | 96 | |

| 6 | Single Jersey | Top Knit | KM-3WV4T | Korea | 2009/9 | 32″ | 24 | 96 | |

| 7 | Single Jersey | Top Knit | KM-3WV4T | Korea | 2009/9 | 32″ | 24 | 96 | |

| 8 | Interlock | Top Knit | KR2TIV | Korea | 2009/9 | 38″ | 24 | 76 | |

| 9 | Single Jersey | Top Knit | KRB2TIV | Korea | 2009/9 | 36″ | 24 | 72 | |

| 10 | Single Jersey | Top Knit | KM3SF | Korea | 2009/9 | 34″ | 24 | 102 | |

| 11 | Single Jersey | Top Knit | KM3WV4T | Korea | 2009/9 | 34″ | 24 | 102 | |

| 12 | Single Jersey | Top Knit | KM4WV4T | Korea | 2009/9 | 36″ | 24 | 144 | |

| 13 | Single Jersey | Top Knit | KM3WV3T | Korea | 2009/9 | 36″ | 24 | 108 | |

| 14 | Single Jersey | Top Knit | KM4WV4T | Korea | 2009/9 | 36″ | 24 | 144 | |

| 15 | Single Jersey | Top Knit | KM3WV3T | Korea | 2009/9 | 38″ | 24 | 114 | |

| 16 | Single Jersey | Top Knit | KM3WV4T | Korea | 2009/9 | 38″ | 24 | 114 | |

| 17 | Single Jersey | Top Knit | KM4WV4T | Korea | 2009/9 | 40″ | 24 | 160 | |

| 18 | Single Jersey | Top Knit | KM3WV3T | Korea | 2009/9 | 42″ | 24 | 126 | |

| 19 | Single Jersey | Top Knit | KM3WV3T | Korea | 2009/9 | 44″ | 24 | 132 | |

| 20 | Single Jersey | Top Knit | KM3WV3T | Korea | 2009/9 | 46″ | 24 | 138 | |

| 21 | Single Jersey | Top Knit | KM3WV3T | Korea | 2009/9 | 48″ | 24 | 144 | |

| 22 | Interlock | Top Knit | KRB2TIV | Korea | 2009/9 | 34″ | 24 | 66 | |

| 23 | Single Jersey | Top Knit | KM3WV4T | Korea | 2009/9 | 34″ | 24 | 102 | |

| 24 | Single Jersey | Top Knit | KM3WV4T | Korea | 2009/9 | 34″ | 24 | 102 | |

| 25 | Single Jersey | Top Knit | KM3WV4T | Korea | 2009/9 | 32″ | 24 | 96 | |

| 26 | Single Jersey | Pai Lung | PLIXS3B/C | Taiwan | 2006/11 | 28″ | 24 | 2112 | 84 |

| 27 | Single Jersey | Pai Lung | PL/XS3B/C | Taiwan | 2006/11 | 28″ | 24 | 2112 | 84 |

| 28 | Single Jersey | Pai Lung | PL/S3B/A/CE | Taiwan | 2007/3 | 25″ | 24 | 1872 | 74 |

| 29 | Single Jersey | Pai Lung | PL/XS3B/C | Taiwan | 2006/11 | 23″ | 24 | 1728 | 68 |

| 30 | Single Jersey | Pai Lung | PL/XS3B/C | Taiwan | 2006/11 | 21″ | 24 | 1584 | 62 |

| 31 | Single Jersey | Pai Lung | PL/XS3B/C | Taiwan | 2006/11 | 19″ | 24 | 1428 | 56 |

| 32 | Single Jersey | Pai Lung | PL/XS3B/C | Taiwan | 2006/11 | 19″ | 24 | 1428 | 56 |

| 33 | Single Jersey | Pai Lung | PL/XS3B/C | Taiwan | 2006/11 | 30″ | 24 | 2256 | 30 |

| 34 | Single Jersey | Pai Lung | PL/XS3B/C | Taiwan | 2006/11 | 34″ | 24 | 2544 | 102 |

| 35 | Single Jersey | Pai Lung | PL/XS3B/C | Taiwan | 2006/11 | 36″ | 24 | 2712 | 108 |

| 36 | Interlock | Mayer & Cie | OV3/2QC | Germany | 2001 | 30″ | 24 | 2268*2 | 106 |

| 37 | Interlock | Mayer & Cie | OV3/2QC | Germany | 2001 | 30″ | 24 | 2268*2 | 106 |

REMARKS:

Production runs with the help of mechanical fitters. For any kind of mechanical fault of any machine the fix and work under technical in charge. Production officers take account of daily production by running after the supervisor and workers so on.

| 38 | Rib | Mayer & Cie | FV2,O | Germany | 2001 | 30″ | 16 | 1512*2 | 159 |

| 39 | Rib | Mayer & Cie | FV2,O | Germany | 2001 | 34″ | 16 | 1704*2 | 159 |

| 40 | Double Jersey | Pai Lung | L-XRA/CE | Taiwan | 2007/3 | 40″ | 18 | 2256 | 80 |

| 41 | Single Jersey | Mayer & Cie | MV4-3,2 | Germany | 2001 | 24″ | 24 | 1800 | 106 |

| 42 | Single Jersey | Mayer & Cie | MV4-3,2 | Germany | 2001 | 22″ | 24 | 1656 | 106 |

| 43 | Single Jersey | Mayer & Cie | MV4-3,3 | Germany | 2001 | 20″ | 24 | 1512 | 106 |

| 44 | Single Jersey | Mayer & Cie | MV4-3,4 | Germany | 2001 | 18″ | 24 | 1368 | 106 |

| 45 | Auto striper single jersey | Pai Lung | N/A | Taiwan | N/A | 30” | 24 | 2256 | 42*6 |

| 46 | Auto striper single jersey | Pai Lung | N/A | Taiwan | N/A | 30” | 24 | 42*6 | |

| 47 | Auto striper single jersey | Pai Lung | N/A | Taiwan | N/A | 34” | 24 | 48*6 | |

| 48 | Auto striper single jersey | Pai Lung | N/A | Taiwan | N/A | 32” | 24 | 44*6 | |

| 49 | Auto striper single jersey | Pai Lung | N/A | Taiwan | N/A | 30” | 24 | 42*6 |

Important equipment of circular knitting machine:

1. Start/ Stop/ Inch Buttons: Complete set of easily accessible start/ stop/ inch button at top in each leg.

2. Rachet Lever: Permit hand movement of the M/C.

3. Auto Stop Motion: Automatic three stages 24v yarn motion, positive feed tapes & knitting zone. Indicatos lamps are on individual stop motions & on the main control panel. While the yarn is broken we can find the location which is broken as well as to repair, mean while the motor can brake and stop operation at once to keep the security of M/C.

4. Free Standing Side Creel: With an active reserve package for each feed.

5. Auto-Counter: Two shift revolution with display counter with predetermined stop, to settle freely the weight or yardage of fabric.

6. Variable Speed Drive with M/C Brake: Transistor invertors provided for free controlled, the process of “V.S.motor drive” from slow operation to normal operation is quite & fast brake to prevent damages in case of needles or yarn breakage.

7. Fabric Take-Up System: With variable speed control by a belt drive ser can be adjusted the speed for different course of fabric- constant and uniform fabric tension.

8. Safety Guard Switch: Machine cannot be atarted woth guards open, this guard have reinforced fiberglass window for easy fabric inspection.

9. Auto Lubrication: The automatioc central pressurized oil sprayer can be adjusted at cycling time and quantity to make sylinder, dial, sinker ring’s cam, neddles and sinkers lubricated enough, besides it has the function coolung and clearing.

10. Auto Line Removal Systems: Three fans on each rotating arm for clearing off any dust of creel and knitting zone.

PRODUCTION PLANNING AND OPERATIONS OF KNITTING DIVISION

PROCESS DEFINITION:

Knitting is the interlocking of one or more yarns through a series of loops. The length wise columns of stitches, corresponding to the warp in woven cloth, are called WALES; the cross wise rows of stitches, corresponding to the filling in woven cloth, are called COURSES, FILLING KNITS (WEFT KNITS) are those fabrics in which the courses are composed of a single strand of yarn, while warp knits are those in which the Wales are composed of single strand of yarn. GAUGE corresponds to the yarn in a woven fabric, and is defined as the number of needles of yarns in half inches of cloth. The higher the gauge, the more compact and finer is the cloth.

DESCRIPTION OF PRODUCTION PROCESS:

In every mill, there maintains a sequences in production processing. It is also followed in this mill where we were in industrial attachment. The process sequences are in list below:

1) Firstly, knitting manager gets a production shit from the merchandiser as accordance as consumer requirements then he informs or orders production officer about it.

2) Production officer informs technical in charge and knows about machine in which the production will be running.

3) Technical in charge calls for leader of mechanical fitter troops, they two take decision about machine for production considering machine condition, production capacity, maintenance complexity, etc.

4) Production officer with experienced mechanical fitter adjusts required stitch length and grey GSM for required final GSM.

5) Supervisor checks daily production regularity and make operator conscious about finishing tin due time.

6) Operators operate machine in high attention as if there were no faults in the fabrics. If he thinks or sure about any fabric fault, then he calls for the mechanical fitters in duty. Mechanical fitter then fixes it if he can or he informs technical in charge. Then he comes in spot.

7) After required production and final inspection in 4-point system, they sent in dyeing section.

Production Flow Chart

Executive director takes order from Buyer

Merchandiser estimates total amount of yatn of production

Kintting manager gets production order sheet

K.M orders senior production officer followed by

Production officer and technical in-charge

Production officer fixes up stitch length and G.S.M with mechanical filter

Definite operator operates machine in his full conscious and attention

Mechanical fitter fixes machine if there is any m/c fault

Supervisors keep daily production report and assure m/c is OK

Fabric roll is checked by a troop of inspectors in inspection unit and weighted

Final product to the required amount is delivered to dyeing unit.

PROCESS REQUIREMENTS:

We have already discussed there are basically three kinds of machine which is used to produce knit fabric and these are:

1. Circular knitting machine (Single Jersey Machines).

2. Circular knitting machine (Double Jersey Machines).

3. Flat knitting machine.

PRODUCTION PARAMETERS:

- Machine Diameter;

- Machine rpm (revolution per minute);

- No. of feeds or feeders in use;

- Machine Gauge;

- Count of yarn;

- Required time (M/C running time);

7. Machine running efficiency.

CONSIDERABLE POINTS TO PRODUCE KNIT FABRICS:

When a buyer orders for fabric then they mention some points related to production and quality. Before production of knitted fabric, these factors are needed to consider. Those are as follows-

- Type of Fabric or design of Fabric.

- Finished G.S.M.

- Yarn count

- Types of yarn (combed or carded)

- Diameter of the fabric.

- Stitch length

- Color depth.

1. G.S.M:

It is technical term that indicates the weight of the fabric pre square meter.

2. Changing of G.S.M:

The G.S.M of the fabric is change by altering the positive of the tension pulley. If the pulley moves towards the positive direction then the G.S.M is decrease and in the reverse direction G.S.M will increase.

3. Points that should consider in case of G.S.M changing:

- VDQ (Variable Dia. Quality Control) pulley diameter.

- Yarn Count

- M/C gauge

- Cam position

- Take up motion

4. Factors that should be considered for changing of fabric design on:

- Cam arrangement changing

- Needle but set & needle dropping

- Using of different colors in selected feeder.

5. Recommendable points of a buyer:

- Diameter of the fabric

- Design of the fabric

- GSM of the fabric

- Total weight of the fabric

- Yarn count

- Types of yarn

- Color of the fabric

- Finishing of the fabric

- Handling & fastness property

6. Gauge Numbers that are usually seen in different M/C:

- Incase of rib m/c. 16to 18 are normally used. But incase of improved quality yarn 20 G m/cs are used in European country.

- Single jersy m/c is normally found 20, 24, 28 etc. gauges.

7. Relation between Yarn Count and M/C gauge:

We know,

G

Ne= ———-

18

Where, Ne = English Cotton count

G = M/C gauge.

FACTORS THAT SHOULD BE CHANGED IN CASE OF FABRIC DESIGN ON QUALITY CHANGE:

a) Cam setting

b) Set of needle

c) Size of loop shape

EFFECT OF STITCH LENGTH ON COLOR DEPTH:

If the depth of color of the fabric is high loop length should be higher because in case of fabric with higher loop length is less compact. In dark shade dye take up% is high so GSM is adjusted then. Similarly in case of light shade loop length should be relatively smaller.

COMPANY DIRECTORY

Management

- Group Chairman : M. A. SABUR

- Managing Director : AHMED ARIF BILLAH

- Director : MS. FAHIMA AKHTER

- Director : MS. FARHANA AKHTER

- Director (Operations) : ATM MAHBUBUL ALAM CHOWDHURY.

As a composite project, the enterprises have been organized in the following manner:

- Masco Group : Corporate Head Office

- Masco Knitting Unit : Fabric Knitting – Project in operation.

- Masco Dyeing Unit : Fabric Dyeing – Projects in operation.

- Masco Washing Unit : Fabric washing – Projects in operation

- Masco Garments Unit-1 : Garments Manufacturing

-Project in operation

- Masco Garments Unit-2 : Garments Manufacturing

-Project in operation

- MPL Wear Ltd : Garments Manufacturing

-Project in operation

- Mascotex Limited : Garments Manufacturing

-Project in operation

- Masco Embroidery Uni : Embroidery Unit

-Projects in Operation.

- Masco Yarn Dyeing Unit : Yarn Dyeing

-Project is under implementation

- Masco Printing Unit : Printing Unit

-Project in operation

Location

The head office is located at a prestigious business area called Uttara which is near to the Dhaka international Airport. 9th & 10th processes of the Yarn Dyeing & Flat Bed All over Printing unit are located at Narsingdi and the projects are under implementation. Others processes (2nd, 3rd, 4th, 5th & 6th) are located at Gazipura, Tongi which is only 7 kms North from Dhaka International Airport.

Head Office : Masco Center

House # 06, Road # 01, Sector # 03

Jashimuddin Avenue, Uttara.

Dhaka – 1230, Bangladesh.

Factory : 221-223 Khartail, Shataish Road

Tongi, Gazipur- 1712, Bangladesh

Phone: 88-02-9813362, 9810790-91, 9815041-42

Fax : 88-02-9810790

Nature of Project : 100% Export Oriented Composite Knit Garments Industry

Year of Establishment : June 2001

Quality Certification : ISO 9002

Oeko-Tex

Walt Disney

Control Union Certifications

Present Buyers:

- New Wave (Sweden)

- Umbro (UK)

- Aldi (Germany)

Zara (Spain) - Stradivarius (Spain)

- Bershka (Spain)

- Big Star (Poland)

TK International (Germany) - Lonsdale (UK)

- Tchibo(German)

- H & M

- C & A

- KIK

| Countries of Exports: | A) Germany C) Sweden E) Italy G) United Kingdom I) Poland K) Austria M) Belgium | B) Spain D) The Netherlands F) France H) Norway J) Finland L) Denmark |

Countries of Imports:A) Hong Kong

B) China

C) Korea

D) Thailand

E) Taiwan

Factory is totally equipped and conditioned to cover requirements for International and National Social Compliance, some features of which are as follows:

Stair cases : 2 Six feet wide spacious stair cases with one emergency evacuation

Wash room & toilet : 1: 25 Persons

“Exit” signs : Exit signs are marked clearly for emergency evacuation

Medical facility : One M.B.B.S doctor caters to the health needs of the workers

Emergency Medical : Trained team of staff & workers to take initiatives in case of emergencies

First Aid : Adequate First Aid Boxes/Kits are placed at different places

Emergency Tele No. : Lists containing emergency Telephone numbers such as Fire Brigade, Hospitals & Police Stations hanged for emergency needs

Fire Extinguisher : Fire extinguishers are placed in a very balanced manner

Fire Drill : Weekly fire drills are initiated

Emergency Light : Emergency lights are there to use in case of power failure

Alternative Power : 316 KVA U.S. made Power Generator (Cummins) is used in Garments unit as source for instant supply of sufficient power for smooth operation during the power cut from national power supply grid. The Dyeing Factory has a 500 KVA Gas Generator for continuous supply of electricity in Dying and Finishing unit.

Work Environment : An excellent work environment exists in the Factory. Adequate ventilation & bright electric light is provided. Music & public address systems are always there inside the Factory.

Child labors : No child labor is allowed to work as per company policy

Day Care Center : The Company runs a day care center for workers children

Weekly Holiday : The Company follows the 7th day rest policy for each and every worker

CHAPTER-02

HUMAN RESOURCE

MANAGEMENT

MANPOWER MANAGEMENT

Management System:

The company has skilled administration, management and marketing team guided by proficient, dexterous & experienced leaders of offer right solution for the consumers with the right eminence & with the shortest lead-time for the export market in Bangladesh.

The best use of continuous development of human resources by providing them International standard equal opportunity is the keys for achieving comprehensive competence in all level of the organizational hierarchy.

ORGANOGRAM OF KNITTING SECTION

ORGANOGRAM OF UTILITY SECTION

Manpower in Dyeing Section:

| Section | Strength | ||

| Staff | worker | Total | |

| Administration | 14 | 19 | 33 |

| Accounts | 3 | 0 | 3 |

| Knitting | 24 | 94 | 118 |

| Dyeing | 12 | 58 | 70 |

| Finishing | 9 | 70 | 79 |

| Maintenance | 14 | 21 | 35 |

| Quality | 16 | 13 | 29 |

| Laboratory | 9 | 2 | 11 |

| Batch | 3 | 25 | 28 |

| Sample | 4 | 0 | 4 |

| Wash | 7 | 7 | 14 |

| Chemical store | 4 | 5 | 9 |

| Security | 7 | 15 | 22 |

| Yarn dyeing | 6 | 8 | 14 |

| Mudafa printing | 4 | 3 | 7 |

| G. Total | 141 | 365 | 506 |

Responsibilities of Production Manager:

- To plan the production schedule with capacity & volume of order.

- To observe dyeing finishing.

- To arrange necessary raw materials for production

- To follow the production and to give solution to the production problems

- To supervise senior production officer & production officer.

- To rectify any kinds of problems during dyeing.

- To follow up the instruction of managing director and executive director as well.

Responsibility of production officer:

- To give dyeing program slip.

- To check recipe.

- T o match production sample with target shade.

- Monitoring Batch preparation & pH checking.

- To collect production sample for sample matching next production.

- To observe dyed fabric during finishing running also after finishing.

- To find out dyeing & fabric fault as early as possible.

- To recover the finished fabric this is rejected from quality department.

- To discuss with DGM about overall production if necessary.

- To sign the store requisition and delivery shipment in the absence DGM.

- Control of supervisor, operator, asstt. operator & helper of dyeing floor.

- To register each batch dyeing condition.

- To check daily production report.

- To check water level in dyeing stage.

- To maintain connection with finishing & quality control department.

- To maintain connection with maintenance department etc.

- To recover the finished fabric this is rejected from quality department.

- To recover the finished fabric this is rejected from quality department.

- To recover the finished fabric this is rejected from quality department.

Job description of Production officer:

Job title : Production officer and senior production officer.

Report to : Production Manager.

Purpose : To control shift according to the plan made by production Manager.

Area : dyeing section (major), Batching and Finishing section (minor).

Job description of production officer:

Report To : Senior production officer.

Job Summary : To plan execute & follows up the production activities & control the quality production with related activities

Duties & Responsibilities:

- Overall supervision of dyeing, finishing production.

- Batch preparation & pH check.

- Dyes & chemical requisition issue & check.

- Write fabrics loading time from m/c.

- Program making sample checking color management.

- Control the supervisors, operator, and helpers of dyeing m/c.

- And also any other work as & when required by the management.

Job description of senior production Officer:

Report to : P.M (production).

Job Summary : To plan execute& follow up the production with related activities.

Duties & Responsibilities:

- Overall supervision of the dyeing finishing production.

- Checks the different log books of different areas report to management.

- Checks the sensitive parameters of deferent machines for smooth dyeing.

- Maintain of machine & equipment any other work & when required by the management.

- Control the supervisor operator ass, operator, helpers of dyeing machine.

Remarks:

The Manpower management system is well arranged in Masco Industries Ltd . Every officer & stuffs are responsible to their duty. But there are only seven textile engineers in the industry. It is sufficient for bulk production. The efficiency of the worker should be increased for, more quality production.

CHAPTER-3

RAW MATERIALS

Following are the different qualities of yarn that are used for knitting process:

SL.No | Yarn composition | Count |

1. | 100% Cotton | 20/1 Ne |

24/1 Ne | ||

26/1 Ne | ||

28/1 Ne | ||

30/1 Ne | ||

32/1 Ne | ||

34/1 Ne | ||

40/1 Ne | ||

60/1 Ne | ||

2. | Lycra | 20 Denier |

40 Denier | ||

3.

| Grey Mellange(95% Cotton 15% Viscose) | 26/1 Ne |

28/1 Ne | ||

30/1 Ne | ||

34/1 Ne | ||

40/1 Ne | ||

4. | Polyester | 75 Denier |

150 Denier | ||

5. | CVC(60%Cotton 40% Polyester) | 20/1 Ne |

24/1 Ne | ||

26/1 Ne | ||

28/1 Ne | ||

30/1 Ne | ||

32/1 Ne | ||

34/1 Ne | ||

40/1 Ne | ||

6. | Dyed Yarn | 20/1 Ne |

24/1 Ne | ||

26/1 Ne | ||

28/1 Ne | ||

30/1 Ne | ||

32/1 Ne | ||

34/1 Ne | ||

40/1 Ne | ||

60/1 Ne |

PRODUCT VARIATION

● Name of product mix :

The product, which are available in knit dyeing floor are given below:

→ Single jersey / Single jersey with lycra.

→ Polo pique, Lacost (Single / Double).

→ Rib – (1×1), (2×2),

→ Lycra Rib, Drop needle fabric.

→ Inter lock.

→ Grey mélange.

→ Stripe (S/J, rib, interlock, grey mélange)

For cotton / Blend / CVC fabric:-

→ S/J without lycra –

Fabric G.S.M | Yarn Count |

110 – 120 | 40 S – 36 S |

120 – 130 | 36 S – 32 S |

130 – 140 | 32 S – 28 S |

140 – 150 | 28 S |

150 – 160 | 26 S |

170 – 210 | 24 S |

→ Rib without lycra –

Fabric G.S.M | Yarn Count |

180 – 190 | 36 S – 32 S |

190 – 200 | 30 S |

200 – 215 | 28 S |

215 – 230 | 26 S |

230 – 250 | 24 S |

250 – 300 | 24 S |

→ Interlock without lycra –

Fabric G.S.M | Yarn Count |

200 – 220 | 34 S |

220 – 230 | 32 S |

230 – 250 | 30 S |

250 – 300 | 26 S |

→ Lacost ( S/L, D/L ) without lycra –

Fabric G.S.M | Yarn Count |

180 – 190 | 30 S |

190 – 210 | 28 S |

210 – 230 | 26 S |

230 – 250 | 26 S |

→ 40D Lycra Rib –

Fabric G.S.M | Yarn Count |

230 – 240 | 32 S |

240 – 250 | 30 S |

250 – 280 | 26 S |

280 – 300 | 24 S |

→ 40D Lycra S/J –

Fabric G.S.M | Yarn Count |

180 – 190 | 34 S |

190 – 210 | 32 S |

210 – 220 | 30 S |

220 – 240 | 28 S |

240 – 250 | 26 S |

Source of yarn for knitting:

- Creora, Korea

- Texlon, Korea

- Techno

- Badsha Winsome

- Nahar spinning Asia

- AML Malek spinning

- Daicoung PTHM for Slub

- Square textile Amber spinning

- Prime S.Pur

- Zaber Rswm

- Mahima Maral Overseas

- Paradise spinning Techno (poly tex)

- Ibrahim Bengal textile

- N.Z Textile Shameem

- GPI textile Asian textile

- Kamal Hazrat Amanat Shah

- Sunson textile NRG

Price of Cotton yarn:

Yarn Count | Combed Yarn | Carded Yarn |

40/1 | 3.65 $/Kg | 2.65-2.7 $/Kg |

34/1 | 3.00 $/Kg | 2.5-2.6 $/Kg |

32/1 | 2.90 $/Kg | 2.30 $/Kg |

30/1 | 2.70 $/Kg | 2.30 $/Kg |

28/1 | 2.70 $/Kg | 2.25 $/Kg |

26/1 | 2.65 $/kg | 2.25 $/Kg |

24/1 | 2.60 $/Kg | 2.25 $/Kg |

22/1 | 2.55 $/Kg | 2.20 $/Kg |

20/1 | 2.50 $/Kg | 2.15-2.2 $/Kg |

FABRIC TYPES:

1) Single Jersey

- Single jersey (Plain)

- Single lacoste

- Double lacoste

- Polo pique

- Fleece fabric

2) Double jersey

- Rib fabric

- 1×1 Rib

- 2×1 Rib

- 2×2 Rib

- Lycra Rib

b. Interlock Fabric

- Plain interlock

3) Back Brush.

4) Collar and Cuff

- Plain Collar or Solid collar

- Stripe Collar.

Dyes and chemicals used by Masco industries Ltd.

Name of the Dyes/Chemicals | Supplier Name | S/R | Name of the Chemicals | Supplier Name | |

| Albafix ECO | Huntsman | 43. | Drimarine Red CL5B | Clariant | |

| Albafix FRD | Huntsman | 44. | Drimarine Blue CLBR | Clariant | |

| Albafluid C | Huntsman | 45. | Drimarine Blue HFRL | Clariant | |

| Carite CBB | Huntsman | 46. | Darimagen E2R Liq. | Clariant | |

| Eriopon R | Huntsman | 47. | Bactasol SAP Liq. | Clariant | |

| Invatex CRA | Huntsman | 48. | Ladiquest 1097 Liq. | Clariant | |

| Novacron FN-2BL | Huntsman | 49. | Asntimusol HTS Liq. | Clariant | |

| Uvitex BHV Liq. | Huntsman | 50. | Sirrix 2UD Liq. | Clariant | |

| Clarite BB | Huntsman | 51. | Drimarine Turquoise CLB | Clariant | |

| Novacron Blue FN-R | Huntsman | 52. | Drimarine Yellow HF3GL | Clariant | |

| Novacron Brilliant red FN3 | Huntsman | 53. | Drimarine Yellow CL2R | Clariant | |

| Novacron Ocean S-R | Huntsman | 54. | Oleophobol CO | Huntsman | |

| Novacron W-B | Huntsman | 55. | Matexil NSB | CRODA | |

| Novacron Ruby S-3B | Huntsman | 56. | Matexil ADW | CRODA | |

| Novacron Super Black G | Huntsman | 57. | Synozol Red HB | KISCO | |

| Novacron Yellow FN-2R | Huntsman | 58. | Synozol Yellow HB | KISCO | |

| Novacron Yellow S- 3R | Huntsman | 59. | Synozol Navy Blue HB | KISCO | |

| Univadine TOP | Huntsman | 60. | Synozol Deep Red HB | KISCO | |

| Cepamine CWS | Huntsman | 61. | Synowhite 4BK | KISCO | |

| Uvitex 2B Conc | Huntsman | 62. | Kemifix Yellow FRL | LOXIM | |

| Primafast 100 | Zenencore | 63. | Kemifix Blue F2R | LOXIM | |

| Catalase T100 | Zenencore | 64. | Kemifix Black GR | LOXIM | |

| Imacozine Red E-3BF | Impocolor | 65. | Kemifix Yellow F4G | LOXIM | |

| Imcozine Yellow E-3R | Impocolor | 66. | Kemifix Red 3BS | LOXIM | |

| Imcozine Turquoise V-G | Impocolor | 67. | Kemifix Orange 2RL | LOXIM | |

| Imcozine V-4GL | Impocolor | 68. | Kemazol Black B | LOXIM | |

| Imcozine Golden Yellow VR | Impocolor | 69. | Drimarine Blue CLBR | Clariant | |

| Imcozine Red V-F3B | Impocolor | 70. | Drimarine Vilot K2R | Clariant | |

| Levafix Fast Red CA | Dystar | 71. | Drimarine Blue K2RL | Clariant | |

| Remazol Yellow RR | Dystar | 72. | Novacron Dark Blue WR | Huntsman | |

| Remazol Brilliant Blue BB | Dystar | 73. | Navacron Blue SGL | Huntsman | |

| Remazol Brilliant Blue Rspl | Dystar | 74. | Amron Amber HR2D | AMTEX | |

| Remazol Red RR | Dystar | 75. | Amron Yellow HR2D | AMTEX | |

| Remazol Brilliant Yellow 3G | Dystar | 76. | Amron Red HR2D | AMTEX | |

| Remazol Blue RR | Dystar | 77. | Amron Blue HR2D | AMTEX | |

| Levafix Blue CA | Dystar | 78. | Amron Red HR6BF | AMTEX | |

| Remazol Ultra Red RGB | Dystar | 79. | Amron Navy HR2D | AMTEX | |

| Levafix Amber CA | Dystar | 80. | Amron Yellow 3BXF | AMTEX | |

| Remazol GoldenYellow RGB | Dystar | 81. | Amron Red 3BXF | AMTEX | |

| Remazol Orange RR | Dystar | 82. | Imerol PCLF | Clariant | |

| Remazol Navy RGB | Dystar | 83. | Anticrease 200 | BUMPO | |

| Remazol Blue RGB | Dystar | 84. | Stagen B | BUMPO | |

| Invatex AC | Huntsman | 93. | Elbezol Yellow 3RS | Elbe Int. | |

| Imcozine Navy Blue E2G | Impocolor | 94. | Elbezol Navy BF | Elbe Int. | |

| Corazol Red RD | Chemi Enterp | 95. | Acetic Acid | Jubilant | |

| Corazol Yellow RD | Chemi Enterp | 96. | Soda Ash | ICI | |

| Ambron Black HR2D | AMTEX | 97. | Glauber’s Salt | JTAC | |

| Supra Red S2B | WIDTEX | 98. | Hydrosulphite | BASF | |

| Elbazol Black WNN | Elbe Int. | 99. | Caustic Soda | ASM Enterp. | |

| Elbezol Red 3BSN | Elbe Int. | 100 | Hydrogen Peroxide | HP | |

CHAPTER- 4

KNITTING SECTION

Layout of Knitting Section:

Knitting Section:

Knitting section is divided in four sections.

- Inspection section

- Flat knitting section

- Circular knitting section

- Store section

1. Cloth inspection section:

In cloth inspection section two machines are available. Specification of those machines is given below:

Type : Cloth Inspection Machine

Manufacture : UZU Fabric Inspection

Country : Turkey

Model No. : N/A

2. Flat knitting section:

Generally collar cuff of knitted garments is produced in this section. In this section there are 06 flat knitting machines. All of them are same type and also have same specification all machines is given below:

Type : Fully Automatic Flat

Manufacture name : Around Star

Country : China

Model No. :AS-318J

Type : Fully Automatic Flat

Manufacture name : Matsuya

Country : Japan

Model No. :M-100

3. Circular Knitting Section:

This section contains 13 circular knitting machines. Circular knitting machines are of different types, made by different manufacture and also have different specification. In this section body fabric for knitted garments is produced. The different specifications of different machines are given one after another.

Process flow chart of knitting:

Yarn in cone form

Feeding the yarn cone in the creel

Feeding the yarn in the feeder via trip-tape positive feeding arrangement and

Tension devices

Knitting

Withdraw the rolled fabric and weighting

Inspection

Numbering

| M/C no | Machine type | Brand Name | Model No | Origin | Manuf. Date | M/C Dia | M/C Gauge | No of Needle | No of Feeder |

| 1 | Single Jersey | Top Knit | KM-3WV4T | Korea | 2009/9 | 26″ | 24 | 78 | |

| 2 | Single Jersey | Top Knit | KM-3SF | Korea | 2009/9 | 30″ | 24 | 90 | |

| 3 | Single Jersey | Top Knit | KM-3WV4T | Korea | 2009/9 | 30″ | 24 | 90 | |

| 4 | Single Jersey | Top Knit | KM-3WV4T | Korea | 2009/9 | 30″ | 24 | 90 | |

| 5 | Single Jersey | Top Knit | KM-3WV4T | Korea | 2009/9 | 32″ | 24 | 96 | |

| 6 | Single Jersey | Top Knit | KM-3WV4T | Korea | 2009/9 | 32″ | 24 | 96 | |

| 7 | Single Jersey | Top Knit | KM-3WV4T | Korea | 2009/9 | 32″ | 24 | 96 | |

| 8 | Interlock | Top Knit | KR2TIV | Korea | 2009/9 | 38″ | 24 | 76 | |

| 9 | Single Jersey | Top Knit | KRB2TIV | Korea | 2009/9 | 36″ | 24 | 72 | |

| 10 | Single Jersey | Top Knit | KM3SF | Korea | 2009/9 | 34″ | 24 | 102 | |

| 11 | Single Jersey | Top Knit | KM3WV4T | Korea | 2009/9 | 34″ | 24 | 102 | |

| 12 | Single Jersey | Top Knit | KM4WV4T | Korea | 2009/9 | 36″ | 24 | 144 | |

| 13 | Single Jersey | Top Knit | KM3WV3T | Korea | 2009/9 | 36″ | 24 | 108 | |

| 14 | Single Jersey | Top Knit | KM4WV4T | Korea | 2009/9 | 36″ | 24 | 144 | |

| 15 | Single Jersey | Top Knit | KM3WV3T | Korea | 2009/9 | 38″ | 24 | 114 | |

| 16 | Single Jersey | Top Knit | KM3WV4T | Korea | 2009/9 | 38″ | 24 | 114 | |

| 17 | Single Jersey | Top Knit | KM4WV4T | Korea | 2009/9 | 40″ | 24 | 160 | |

| 18 | Single Jersey | Top Knit | KM3WV3T | Korea | 2009/9 | 42″ | 24 | 126 | |

| 19 | Single Jersey | Top Knit | KM3WV3T | Korea | 2009/9 | 44″ | 24 | 132 | |

| 20 | Single Jersey | Top Knit | KM3WV3T | Korea | 2009/9 | 46″ | 24 | 138 | |

| 21 | Single Jersey | Top Knit | KM3WV3T | Korea | 2009/9 | 48″ | 24 | 144 | |

| 22 | Interlock | Top Knit | KRB2TIV | Korea | 2009/9 | 34″ | 24 | 66 | |

| 23 | Single Jersey | Top Knit | KM3WV4T | Korea | 2009/9 | 34″ | 24 | 102 | |

| 24 | Single Jersey | Top Knit | KM3WV4T | Korea | 2009/9 | 34″ | 24 | 102 | |

| 25 | Single Jersey | Top Knit | KM3WV4T | Korea | 2009/9 | 32″ | 24 | 96 | |

| 26 | Single Jersey | Pai Lung | PLIXS3B/C | Taiwan | 2006/11 | 28″ | 24 | 2112 | 84 |

| 27 | Single Jersey | Pai Lung | PL/XS3B/C | Taiwan | 2006/11 | 28″ | 24 | 2112 | 84 |

| 28 | Single Jersey | Pai Lung | PL/S3B/A/CE | Taiwan | 2007/3 | 25″ | 24 | 1872 | 74 |

| 29 | Single Jersey | Pai Lung | PL/XS3B/C | Taiwan | 2006/11 | 23″ | 24 | 1728 | 68 |

| 30 | Single Jersey | Pai Lung | PL/XS3B/C | Taiwan | 2006/11 | 21″ | 24 | 1584 | 62 |

| 31 | Single Jersey | Pai Lung | PL/XS3B/C | Taiwan | 2006/11 | 19″ | 24 | 1428 | 56 |

| 32 | Single Jersey | Pai Lung | PL/XS3B/C | Taiwan | 2006/11 | 19″ | 24 | 1428 | 56 |

| 33 | Single Jersey | Pai Lung | PL/XS3B/C | Taiwan | 2006/11 | 30″ | 24 | 2256 | 30 |

| 34 | Single Jersey | Pai Lung | PL/XS3B/C | Taiwan | 2006/11 | 34″ | 24 | 2544 | 102 |

| 35 | Single Jersey | Pai Lung | PL/XS3B/C | Taiwan | 2006/11 | 36″ | 24 | 2712 | 108 |

| 36 | Interlock | Mayer & Cie | OV3/2QC | Germany | 2001 | 30″ | 24 | 2268*2 | 106 |

| 37 | Interlock | Mayer & Cie | OV3/2QC | Germany | 2001 | 30″ | 24 | 2268*2 | 106 |

REMARKS:

Production runs with the help of mechanical fitters. For any kind of mechanical fault of any machine the fix and work under technical in charge. Production officers take account of daily production by running after the supervisor and workers so on.

| 38 | Rib | Mayer & Cie | FV2,O | Germany | 2001 | 30″ | 16 | 1512*2 | 159 |

| 39 | Rib | Mayer & Cie | FV2,O | Germany | 2001 | 34″ | 16 | 1704*2 | 159 |

| 40 | Double Jersey | Pai Lung | L-XRA/CE | Taiwan | 2007/3 | 40″ | 18 | 2256 | 80 |

| 41 | Single Jersey | Mayer & Cie | MV4-3,2 | Germany | 2001 | 24″ | 24 | 1800 | 106 |

| 42 | Single Jersey | Mayer & Cie | MV4-3,2 | Germany | 2001 | 22″ | 24 | 1656 | 106 |

| 43 | Single Jersey | Mayer & Cie | MV4-3,3 | Germany | 2001 | 20″ | 24 | 1512 | 106 |

| 44 | Single Jersey | Mayer & Cie | MV4-3,4 | Germany | 2001 | 18″ | 24 | 1368 | 106 |

| 45 | Auto striper single jersey | Pai Lung | N/A | Taiwan | N/A | 30” | 24 | 2256 | 42*6 |

| 46 | Auto striper single jersey | Pai Lung | N/A | Taiwan | N/A | 30” | 24 | 42*6 | |

| 47 | Auto striper single jersey | Pai Lung | N/A | Taiwan | N/A | 34” | 24 | 48*6 | |

| 48 | Auto striper single jersey | Pai Lung | N/A | Taiwan | N/A | 32” | 24 | 44*6 | |

| 49 | Auto striper single jersey | Pai Lung | N/A | Taiwan | N/A | 30” | 24 | 42*6 |

Important equipment of circular knitting machine:

1. Start/ Stop/ Inch Buttons: Complete set of easily accessible start/ stop/ inch button at top in each leg.

2. Rachet Lever: Permit hand movement of the M/C.

3. Auto Stop Motion: Automatic three stages 24v yarn motion, positive feed tapes & knitting zone. Indicatos lamps are on individual stop motions & on the main control panel. While the yarn is broken we can find the location which is broken as well as to repair, mean while the motor can brake and stop operation at once to keep the security of M/C.

4. Free Standing Side Creel: With an active reserve package for each feed.

5. Auto-Counter: Two shift revolution with display counter with predetermined stop, to settle freely the weight or yardage of fabric.

6. Variable Speed Drive with M/C Brake: Transistor invertors provided for free controlled, the process of “V.S.motor drive” from slow operation to normal operation is quite & fast brake to prevent damages in case of needles or yarn breakage.

7. Fabric Take-Up System: With variable speed control by a belt drive ser can be adjusted the speed for different course of fabric- constant and uniform fabric tension.

8. Safety Guard Switch: Machine cannot be atarted woth guards open, this guard have reinforced fiberglass window for easy fabric inspection.

9. Auto Lubrication: The automatioc central pressurized oil sprayer can be adjusted at cycling time and quantity to make sylinder, dial, sinker ring’s cam, neddles and sinkers lubricated enough, besides it has the function coolung and clearing.

10. Auto Line Removal Systems: Three fans on each rotating arm for clearing off any dust of creel and knitting zone.

PRODUCTION PLANNING AND OPERATIONS OF KNITTING DIVISION

PROCESS DEFINITION:

Knitting is the interlocking of one or more yarns through a series of loops. The length wise columns of stitches, corresponding to the warp in woven cloth, are called WALES; the cross wise rows of stitches, corresponding to the filling in woven cloth, are called COURSES, FILLING KNITS (WEFT KNITS) are those fabrics in which the courses are composed of a single strand of yarn, while warp knits are those in which the Wales are composed of single strand of yarn. GAUGE corresponds to the yarn in a woven fabric, and is defined as the number of needles of yarns in half inches of cloth. The higher the gauge, the more compact and finer is the cloth.

DESCRIPTION OF PRODUCTION PROCESS:

In every mill, there maintains a sequences in production processing. It is also followed in this mill where we were in industrial attachment. The process sequences are in list below:

1) Firstly, knitting manager gets a production shit from the merchandiser as accordance as consumer requirements then he informs or orders production officer about it.

2) Production officer informs technical in charge and knows about machine in which the production will be running.

3) Technical in charge calls for leader of mechanical fitter troops, they two take decision about machine for production considering machine condition, production capacity, maintenance complexity, etc.

4) Production officer with experienced mechanical fitter adjusts required stitch length and grey GSM for required final GSM.

5) Supervisor checks daily production regularity and make operator conscious about finishing tin due time.

6) Operators operate machine in high attention as if there were no faults in the fabrics. If he thinks or sure about any fabric fault, then he calls for the mechanical fitters in duty. Mechanical fitter then fixes it if he can or he informs technical in charge. Then he comes in spot.

7) After required production and final inspection in 4-point system, they sent in dyeing section.

Production Flow Chart

Executive director takes order from Buyer

Merchandiser estimates total amount of yatn of production

Kintting manager gets production order sheet

K.M orders senior production officer followed by

Production officer and technical in-charge

Production officer fixes up stitch length and G.S.M with mechanical filter

Definite operator operates machine in his full conscious and attention

Mechanical fitter fixes machine if there is any m/c fault

Supervisors keep daily production report and assure m/c is OK

Fabric roll is checked by a troop of inspectors in inspection unit and weighted

Final product to the required amount is delivered to dyeing unit.

PROCESS REQUIREMENTS:

We have already discussed there are basically three kinds of machine which is used to produce knit fabric and these are:

1. Circular knitting machine (Single Jersey Machines).

2. Circular knitting machine (Double Jersey Machines).

3. Flat knitting machine.

PRODUCTION PARAMETERS:

- Machine Diameter;

- Machine rpm (revolution per minute);

- No. of feeds or feeders in use;

- Machine Gauge;

- Count of yarn;

- Required time (M/C running time);

7. Machine running efficiency.

CONSIDERABLE POINTS TO PRODUCE KNIT FABRICS:

When a buyer orders for fabric then they mention some points related to production and quality. Before production of knitted fabric, these factors are needed to consider. Those are as follows-

- Type of Fabric or design of Fabric.

- Finished G.S.M.

- Yarn count

- Types of yarn (combed or carded)

- Diameter of the fabric.

- Stitch length

- Color depth.

1. G.S.M:

It is technical term that indicates the weight of the fabric pre square meter.

2. Changing of G.S.M:

The G.S.M of the fabric is change by altering the positive of the tension pulley. If the pulley moves towards the positive direction then the G.S.M is decrease and in the reverse direction G.S.M will increase.

3. Points that should consider in case of G.S.M changing:

- VDQ (Variable Dia. Quality Control) pulley diameter.

- Yarn Count

- M/C gauge

- Cam position

- Take up motion

4. Factors that should be considered for changing of fabric design on:

- Cam arrangement changing

- Needle but set & needle dropping

- Using of different colors in selected feeder.

5. Recommendable points of a buyer:

- Diameter of the fabric

- Design of the fabric

- GSM of the fabric

- Total weight of the fabric

- Yarn count

- Types of yarn

- Color of the fabric

- Finishing of the fabric

- Handling & fastness property

6. Gauge Numbers that are usually seen in different M/C:

- Incase of rib m/c. 16to 18 are normally used. But incase of improved quality yarn 20 G m/cs are used in European country.

- Single jersy m/c is normally found 20, 24, 28 etc. gauges.

7. Relation between Yarn Count and M/C gauge:

We know,

G

Ne= ———-

18

Where, Ne = English Cotton count

G = M/C gauge.

FACTORS THAT SHOULD BE CHANGED IN CASE OF FABRIC DESIGN ON QUALITY CHANGE:

a) Cam setting

b) Set of needle

c) Size of loop shape

EFFECT OF STITCH LENGTH ON COLOR DEPTH:

If the depth of color of the fabric is high loop length should be higher because in case of fabric with higher loop length is less compact. In dark shade dye take up% is high so GSM is adjusted then. Similarly in case of light shade loop length should be relatively smaller.

Some are parts:

Industrial Attachment on Masco Industries Ltd (Part 1)

![Report on Overall Banking Practice of National credit and commerce bank [Part-2]](https://assignmentpoint.com/wp-content/uploads/2013/05/images-11-200x79.jpg)