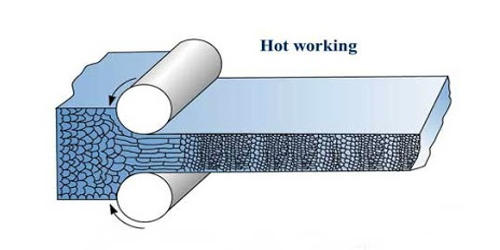

Hot-working improves the engineering properties of the workpiece because it replaces the microstructure with one that has fine spherical shaped grains. Hot working process metals are plastically deformed above their recrystallization temperature. Being above the recrystallization temperature allows the material to recrystallize during deformation. It is a process in which a metal is shaped under pressure at a fairly high temperature. The hot working temperature of metal depends upon the re-crystallization temperature of that metal, for instance, carbon steel requires a temperature greater than 1000 ᵒC (1832 ᵒF) for hot working. This is important because recrystallization keeps the materials from strain hardening, which ultimately keeps the yield strength and hardness low and ductility high. It is used for altering the form of iron and steel without fracture and the use of excessive force.

Many kinds of work, including rolling, forging, extrusion, and drawing, can be done with hot metal. The ultimate goal of metal hot working is to produce metal components of the required structural orientation and geometrical shape. The application of hot metal working includes hot rolling, forging, extrusion, and hot drawing.

Maintaining temperature

The lower limit of the hot working temperature is determined by its recrystallization temperature. Re-crystallization temperature is the temperature at which atomic mobility can be repaired when any defect was present in the metal caused by the working process. As a guideline, the lower limit of the hot working temperature of a material is 60% its melting temperature. The upper limit for hot working is determined by various factors, such as – excessive oxidation, grain growth, or an undesirable phase transformation.

Advantages

- The decrease in yield strength, therefore it is easier to work and uses less energy or force.

- It is applicable to mass production work. The metal size and shape can be easily changed.

- Increase in ductility. Stresses and other defects can be minimized.

- Elevated temperatures increase diffusion which can remove or reduce chemical inhomogeneities

- Pores may reduce in size or close completely during deformation

Hot-working improves the engineering properties of the workpiece because it replaces the microstructure with one that has fine spherical shaped grains. These grains increase the strength, ductility, and toughness of the material.

The disadvantages are:

- Undesirable reactions between the metal and the surrounding atmosphere.

- It leads to poor surface finish due to oxidation, because the material will be worked under high temperature.

- Less precise tolerances due to thermal contraction and warping from uneven cooling.

- Grain structure may vary throughout the metal for various reasons.

- It is difficult to attain dimensional accuracy due to uneven shrinkage of metal.