New high-power electronic devices that use less energy than older technology have been developed by engineers. The devices are made possible by a novel method for carefully “doping” gallium nitride (GaN).

“Many technologies require power conversion where power is switched from one format to another,” says Dolar Khachariya, the first author of a paper on the work and a former Ph.D. student at North Carolina State University. “For example, the technology might need to convert AC to DC, or convert electricity into work like an electric motor. And in any power conversion system, most power loss takes place at the power switch which is an active component of the electrical circuit that makes the power conversion system.”

The power electronics industry is undergoing an innovative transformation because to gallium nitride (GaN). Metal oxide semiconductor field effect transistors (MOSFETs), which are based on silicon, have long played a crucial role in converting energy into power in the modern world.

On many different substrates, including sapphire, silicon carbide (SiC), and silicon (Si), gallium nitride crystals can develop. The existing silicon manufacturing infrastructure may be exploited by growing a GaN epi layer on top of silicon, doing away with the need for pricey specialist production sites and utilizing easily accessible, low-cost big diameter silicon wafers.

“Developing more efficient power electronics like power switches reduces the amount of power lost during the conversion process,” says Khachariya, who is who is now a researcher at Adroit Materials Inc. “This is particularly important for developing technologies to support a more sustainable power infrastructure, such as smart grids.”

“Our work here not only means that we can reduce energy loss in power electronics, but we can also make the systems for power conversion more compact compared to conventional silicon and silicon carbide electronics,” says Ramón Collazo, co-author of the paper and an associate professor of materials science and engineering at NC State.

“This makes it possible to incorporate these systems into technologies where they don’t currently fit due to weight or size restrictions, such as in automobiles, ships, airplanes, or technologies distributed throughout a smart grid.”

We’ve demonstrated that you can selectively dope GaN to create functional JBS diodes, and that these diodes are not only functional, but enable more power efficient conversion than JBS diodes that use conventional semiconductors. For example, in technical terms, our GaN JBS diode, fabricated on a native GaN substrate, has record high breakdown voltage (915 V) and record low on-resistance.

Ramón Collazo

Since gallium nitride can fulfill the expanding demands with improved power systems efficiency, performance, and system cost, it is gaining ground to take the position of silicon as the core of power switching technology.

In a publication released in 2021, the researchers described a method for doping specific regions of GaN materials using ion implantation and activation. To deliberately alter the electrical characteristics of the GaN solely in those places, they introduced impurities into particular sections of GaN materials.

The researchers have shown how this method can be applied to produce genuine devices in their most recent work. To develop Junction Barrier Schottky (JBS) diodes, the researchers specifically employed materials that had been carefully doped with GaN.

Actually, RF components, light-emitting diodes (LEDs), and semiconductor power devices are all made using gaN. GaN has proven to have the potential to replace silicon semiconductors in RF, analog, and power conversion applications.

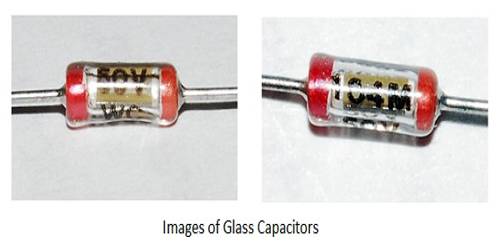

“Power rectifiers, such as JBS diodes, are used as switches in every power system,” Collazo says. “But historically they have been made of the semiconductors silicon or silicon carbide, because the electrical properties of undoped GaN are not compatible with the architecture of JBS diodes. It just doesn’t work.”

“We’ve demonstrated that you can selectively dope GaN to create functional JBS diodes, and that these diodes are not only functional, but enable more power efficient conversion than JBS diodes that use conventional semiconductors. For example, in technical terms, our GaN JBS diode, fabricated on a native GaN substrate, has record high breakdown voltage (915 V) and record low on-resistance.”

“We’re currently working with industry partners to scale up production of selectively doped GaN, and are looking for additional partnerships to work on issues related to more widespread manufacturing and adoption of power devices that make use of this material,” Collazo says.

The paper, “Vertical GaN Junction Barrier Schottky Diodes with Near-ideal Performance using Mg Implantation Activated by Ultra-High-Pressure Annealing,” is published in the journal Applied Physics Express.

The paper was co-authored by Spyridon Pavlidis, an assistant professor of electrical and computer engineering at NC State; Shashwat Rathkanthiwar, a postdoctoral researcher at NC State; Shane Stein, a Ph.D. student at NC State; Hayden Breckenridge, a former Ph.D. student at NC State; Erhard Kohn, a research associate at NC State and emeritus professor of Ulm University in Germany; Zlatko Sitar, Kobe Steel Distinguished Professor of Materials Science and Engineering at NC State and the founder of Adroit Materials; Will Mecouch, Seiji Mita, Baxter Moody, Pramod Reddy, James Tweedie and Ronny Kirste of Adroit Materials; and Kacper Sierakowski, Grzegorz Kamler and Michał Boćkowski of the Institute of High-Pressure Physics at the Polish Academy of Sciences. The work was supported primarily by ARPA-E as part of its PNDIODES program, under grants DE-AR0000873, DE-AR000149.

The work received additional support from the National Science Foundation, under grants ECCS-1916800, ECCS-1508854, ECCS-1610992, DMR-1508191 and ECCS-1653383; the Office of Naval Research Global’s Naval International Cooperative Opportunities in Science and Technology program, under grant N62909-17-1-2004; and Poland’s National Center for Research and Development (NCBR) under grant TECHMATSTRATEG-III/0003/2019-00.