Operation

In the absolute basics, air conditioners used for cooling, work under five basic building blocks. They are- Compression, Condensation, Expansion, Evaporation and boiling and exchange. Here discussed more in detail about compression of gases, as an expansion to the fundamentals of how air conditioners work.

Compression

In short, it is an act of increasing pressure of gas in an enclosed space. Although solids can be compressed to a very limited extent, similarly for liquids; those are not quite related in our world of air conditioners.

Every matter, be it solid, liquid or gas are composed of the most basic of all building blocks. Electrons, neutrons and protons; these will form an atom.

Now, each atom consists of proton/s and neutron/s in its nucleus (analogous to the sun), and electron/s orbiting the nucleus (analogous to planets).

The mass of each building block is in the magnitude of 10-31 kg (for electron), and 10-27 kg for (proton and neutron), those are extremely light. Each of these electron, proton and neutron has a specific internal energy in magnitude of 10-19 Joules.

There are a number of possible proton neutron and electron quantities in an atom. Add a few electrons; you’ll have an atom of copper for example. Add a few more, you might have mercury.

Mix two or more different or even same atom types, you’ll have a molecule.

That’s it. Due to different quantity of electrons, protons and neutrons in a single atom or molecule, we’ll have different types of material, from steel to copper, from water to refrigerants. And due to different quantity of these building blocks, we’ll have different internal energy for each material.

If the internal energy of a matter is much lower compared to the ambient atmosphere, it will be in solid state.

If the internal energy of the same matter is much higher than the ambient atmosphere, it will be in gaseous state.

Anything in between, it will be in liquid state.

Let us consider our natural environment, under natural gravitational pull. The pressure and temperature are ambient. This is the phase where things exist naturally. The state at which, we don’t have to put in energy to get air at gaseous state, or gold in solid state.

Manufacturers of air conditioners used refrigerants, since it has an attractive boiling temperature for heat exchange between air that we live in, and the refrigerant.

But, our atmospheric condition will not allow refrigerant to be in liquid state. Hence, we need to compress it enough, coupled with condensing it, to change the state from gas, to liquid. The energy from compression and condensation overcomes the internal energy of the refrigerant. Hence the state is changed from gas to liquid through compression and condensation.

The condition within the compression cycle is no longer ambient. Hence, we have to put in work to compress the gas and reduce the distances between gas molecules.

Concluding with compression and gas laws

When we talk about gas laws, Boyle’s, Charles’ and Pressure’s law will come into mind.

We have to have a system filled with gas, in an enclosed or restricted space, for these laws to stand.

I am glad to say that air conditioners use compressors connected by a series of tubing and other parts, in a closed loop system. In other words, compression happens in enclosed and restricted condition.

Pressure law states that, for a fixed mass of gas (enclosed system), the pressure (p) in bar is directly proportional to the temperature (T) in Kelvin; maintaining the gas volume (V) in m3. This means that heat is provided (or removed) externally to (or from) the system. Volume is maintained, temperature is increased and as a result, pressure increases (the reverse happens for temperature reduction). This application is used in cannons.

Charles’s law states that, for a fixed mass of gas, the volume (V) is directly proportional to the temperature (T) of the gas, maintaining the system pressure. Heat is provided (or removed) externally, and the gas expands (or contracts) in volume. Hot air balloons use this principle to the max.

Boyle stated that, for a fixed mass of gas, the volume (V) is inversely proportional to the pressure applied (p). Hence, volume will decrease as the pressure is increased.

This compression is an adiabatic compression, if no heat is provided or taken from the system externally. Our favorite air conditioners’ compressors use this principle during compression phase. This principle is also applicable in expansion processes.

I have said that adiabatic compression do not take or give heat due to external influences. However, due to collision of atoms or molecules, temperature within the system will rise.

Since air conditioning systems combine compression, condensation, expansion and evaporation, heat is:

- generated internally through compression

- taken from refrigerant through condensation

- received internally through expansion

- and provided to the refrigerant through evaporation

Finally, we can say that, all the gas laws are used in combination by air conditioner manufacturers, to design a suitable air conditioner compressor.

Condensation

Condensation is the next stage in air conditioners operating cycle, after compression. In other words, this is a side branch to compression page.

This stage is coupled with compression, for two reasons,

- to change the refrigerant’s state from high pressure gas to high pressure liquid

- to avoid having very large compressor to compress refrigerant beyond critical point – i.e. change gas to liquid without going through liquid-vapor phase. In other words, ensuring air conditioners are designed properly.

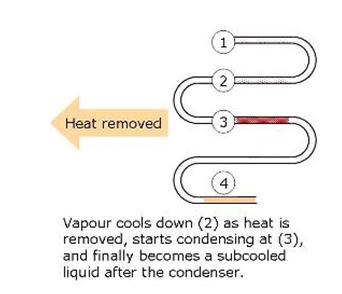

Figure : Condensing process

Although compression alone may change the state of refrigerant from vapor to liquid, it is deemed unpractical for air conditioners’ design. There will only wastage of electricity bills, and might not get cool air in the end. So, condensation is required.

As explained in the fundamentals page, condensation happens mainly in a heat exchanger, through a heat exchange process. That heat exchanger is known as condenser.

Sneak peek into the basics

Every atom and molecule of matters has a specific internal energy, as explained in compression page. And due to this specific internal energy, different matter exists in different state (solid, liquid, or vapor) at a given pressure and temperature.

Solids will have atoms or molecules packed together very closely; hence the movement only involves rotation about each atom or molecule’s axis.

Liquid however, will have a close formation of molecules or atoms. The movement is much more flexible than solids, but still restricted to short distances. Liquid has higher molecule or atomic energy compared to solid, but lower energy compared to vapor.

Vapor has all the freedom in this world, to move in all direction possible, with large distances between each atoms or molecules, high speed and random in motion. It has the highest molecule or atomic energy between solid and liquid.

Condensation wishes to introduce itself:

Condensation is defined as the state when a vapor starts to change phase into liquid state, as a result of temperature drop.

It starts when a superheated vapor reaches its saturation point.

We have to bear in mind that condensation does not occur at a singular temperature. It occurs at different ranges of temperature. Reason is being the pressure of the vapor itself.

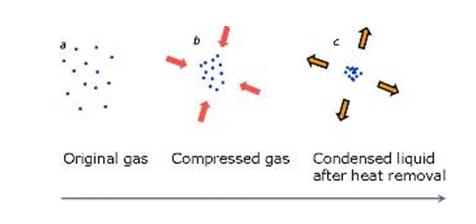

Compression page has explained that increasing the pressure will reduce the distance between the vapor molecules. Thus, vapor molecules will have lower net energy.

Decreasing the pressure will have a reverse effect, where the distance between the molecules will increase, and net molecular energy will increase.

So, if a gas or vapor has a higher net energy, more energy needs to be removed to reduce the distance between the molecules.

Similarly, lower net energy of vapor requires less energy removal for molecules distance to close.

What’s with all the molecule distance and energy removal?

As explained earlier, the molecule distance is a characteristic to different states of a matter solid, liquid, or vapor.

Energy can be in terms of work, or heat. And when condensation is in the picture, energy removal is in terms of heat.

Hence, as the pressure of the vapor increases, the heat removal required is smaller to condense it. This means that condensation of the matter starts to happen at a higher saturation (or boiling) temperature. This is good, as any temperature lower than the saturation temperature, means we will have a condensed liquid.

The flip side occurs for low vapor pressure.

Let us consider Refrigerant 12 as an example.

Referring to Rogers’ and Mayhew’s “Thermodynamic and Transport Properties of Fluids”:

- the saturation temperature at 1 bar is about -30ºC (-22ºF)

- whereas the saturation temperature at 9.6 bar is about 40ºC (104ºF)

This means that we have to have ambient air at -30ºC (-22ºF) for condensation of the refrigerant to occur at ambient pressure.

Well, if we have that kind of ambient temperature, we wouldn’t need cooling anymore.

We see the ambient temperature for the compressed refrigerant does not have to be very low for condensation to occur. In fact the saturation temperature is higher than most ambient temperatures during hot summer. Hence heat exchange occurs from the refrigerant, to ambient air.

This is why we have to couple condensation with compression in air conditioner systems.

Bring the pressure up, close the gap between the gases, and remove the heat from the refrigerant to close the gap even more – liquid refrigerant we have.

Short meeting with vapor and liquid, and the phase in between:

This meeting occurs when heat is continually removed from it.

If all of the matter is in vapor form, then we call it superheated vapor, as there is no condensation.

Once the temperature drops to saturation line, we will have a mix of vapor and liquid. This is the phase in between.

Temperature will not decrease until all vapor within an enclosed space, turn into liquid.

Figure : Gas in three different forms

Once in liquid form, temperature will start to decrease again, until it meets freezing point. But that’s a different story.

Condensation wishes to conclude with real life example:

- Order a glass of iced lemon tea

- Watch condensation of water vapor happening on the glass

Expansion

Expansion phase of liquid refrigerant in air conditioners happens at the critical separation point between high pressure, and low pressure side of air conditioner systems. It is simply the reverse of compression.

As explained in how air conditioners work, this stage follows compression and condensation stage.

Compression and condensation of the refrigerant has already turned it from vapor, to liquid. It will be in that state, irrespective of temperature change within the contained space (i.e. the tubing), as long as the space can withstand the pressure rise or fall.

Compress it, condense it, and hold the pressure. Get these three in harmony, and we will have liquid refrigerant forever.

The critical factor:

At this moment, the only factor that is holding the state of the refrigerant is the high pressure within the air conditioner. We can’t rely on ambient temperature alone (if we are living on earth) to keep it liquefied. Condensation page explains it detail.

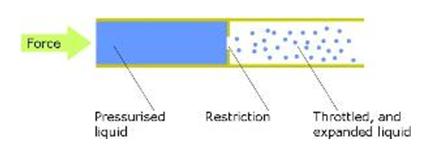

But we want liquid refrigerant to start vaporizing. Thus, we deliberately put a restriction after the condenser.

This restriction has two functions:

- allowing compression to happen

- accelerate and allow liquid refrigerant to expand into low pressure side

And this restriction is called an expansion valve.

Throttling: Expansion can happen in two ways, similar to compression. Expand, slowly with temperature rise, or rapidly with pressure decrease However, construction of the valve that holds high pressure on one side, and facing low pressure on the other, determines the way refrigerant liquid expands rapidly due to pressure drop. In other words, the refrigerant goes through a throttling process

Pressure taken off immediately, molecules become active almost immediately, volume (V) increases rapidly.

Figure : throttling process

If adiabatic compression meant increase in refrigerants temperature, the reverse will mean drop in surrounding temperature. This happens as the refrigerant liquid starts to vaporize.

Throttling as “dessert”:

Throttling act helps expansion and evaporation of liquid through atomizing or breaking a large amount of liquid, into mist.

It is widely used in atomizing fuel for vehicles, and air conditioner refrigerants.

Evaporation and Boiling Into Thin Air

No, refrigerant evaporation and boiling are not allowed into air. Its density is in air conditioners. Sorry, it is harmful and no way will have cooling through air conditioners, if that happens.

Nostalgic moments:

If we have been to How Air Conditioners Work page, evaporation part comes last in air conditioning cycle.

It has two good friends and a best buddy.

The good friends are the compression, and condensation section.

These two has prepared a nice and high pressure refrigerant.

And wow, the best buddy is the expansion, i.e. the throttling part.

This one has done the breaking-the-big-chunk-into-manageable-pieces of the refrigerant, for evaporation to take place.

Two important parts need to explain-

1. In basic understanding, every atom or molecule has a specific internal energy and,

· These atoms will move in random and linear motion (liquid or gas), or vibrate and rotate within its position (solid). More details in here

· Liquid atoms or molecules will have highest energy at the surface of its volume, compared to atoms or molecules beneath it.

- Molecules or atoms of liquid (be it water or liquid refrigerant) inside the volume will have pulling force from neighboring molecules or atoms of the same matter, in all directions.

Unlike its co-molecules inside the volume, counterparts on the surface will only have pulling force in downwards and sideways directions, directly ahead just the surrounding vapor pressure.

This means that the internal energy of the molecules or atoms at the surface, will overcome the pulling forces from the neighboring molecules or atoms, and evaporate into the surrounding atmosphere.

Heat transfer

Heat transfer or heat exchange, is a process of (what some people nickname it as) “heat migration” from a point, to another point (From a point of higher temperature to a point of lower temperature).

Weaving into heat transfer:

We have known that,

- energy is the ability to do work

- energy can be transformed from one form to another

- heat is a form of energy

- heat content depends on the mass of the matter, the matter itself, and the temperature at which the matter is held

Therefore, we can say that heat is a form of energy, heat transfer can occur, and heat is also a function of temperature.

As defined earlier, heat transfer occurs from a point with higher temperature, to another point of lower temperature.

This happens as the point with higher temperature, with higher particle kinetic energy, will transmit the energy, to the point with lower kinetic energy, i.e. lower temperature.

Air conditioning maintenance

Proper and scheduled air conditioning maintenance is essential in making sure that air conditioning unit will be operational as long as possible. A properly maintained air conditioning unit will cost our less in the long run, and we don’t have to go around, looking for a new unit.

Air conditioning maintenance classified into two categories,

- Air conditioning maintenance by user level

- Air conditioning maintenance by trained personnel

Air conditioning maintenance by user level

- Air conditioner filter maintenance

- External cleaning of condenser and evaporator

- Tube insulation care

- Condensate pan and drain care

- Simple damper maintenance

- Acidity test

- Moisture check

- Simple leak detection, and

- Simple fan and blower diagnostic

Air conditioner filter maintenance

- Frequency of maintenance depends on the location of the conditioned room, and intake air condition.

Some would suggest a frequency of once a month, some would suggest once in three months.

The real fact is, there is no fixed frequency. We have to determine the frequency after two or three filter maintenance.

- Maintenance of the filter could be replacing the filter for disposable ones, or washing it for electrostatic filters, or cleaning by blower machine.

Maintaining the condenser and evaporator

- Common phenomenon with the evaporator and the condenser are damaged fins.

This problem is easily identified, and rectified using fin comb

- External cleaning of the condenser and evaporator may be carried out without involving water or cleaning foam.

Combination of fin brush and a vacuum cleaner would do the trick quite nicely.

Use of cleaning foam and water would be the best, but it has to be carried out with the electrical supply isolated, and electrical equipment covered to prevent unnecessary water or cleaning solution ingress.

Tube insulation care

This is probably the least problematic area within an air conditioning unit.

A good check would be, to find damaged parts of the insulation, and exposed parts of the vapor return line.

We need to follow the following ways-

- Get a synthetic rubber tube insulation, matching with the vapor return line size,

- Remove the damaged insulation (if any),

- Cut required length of the insulation, and cover the exposed tube length,

- Secure the insulation by wrapping the ends, with cable tie, or better still, with insulating tapes

Condensate pan and drain care

Condensate pan and drain care is probably the simplest air conditioning maintenance you can perform, but normally overlooked, creating unwanted moss formation, clogging, and evaporator unit flooding.

Maintenance that we perform on monthly basis is,

- Testing the water flow from the pan. Better still, use warm water, mixed with detergent

- Cleaning any debris and dust from drain inlet to prevent clogging,

- Cleaning of condensate pan with detergent and wiping it clean to prevent moss formation,

- Use of wet and dry vacuum cleaner at the outlet of drain line, to pull out dead insects or remaining water within the line

Simple damper maintenance

A damper in air conditioning system may be operated manually, or automatically, using electrical motor, hydraulic system, or pneumatic system.

These dampers will have,

- Linkages, and

- Pivot

Cleaning of these points from dust and debris would prevent seizure of dampers.

Simple spray lubrication may be applied to these points, to prevent squeaking sound. Please make sure to wipe off the excess oil.

This maintenance may be carried out on quarterly intervals.

Acidity test

It is used to check for acidity in the refrigerant, or lubrication oil. This test is extremely important in making sure that the compressor will not fail prematurely, from parts erosion and corrosion.

Acid formation within the system happens due to excessive temperature rise, thus disintegrating the refrigerant into chlorine based, or fluorine based acid.

Normal causes for excessive temperature rise are insufficient lubrication, or insufficient cooling from the return refrigerant vapor.

Moisture check

Moisture within an air conditioner system is equally as bad as acids. Presence of atmosphere will cause ice formation at the low pressure side of the air conditioner, since the temperature will be lower than waters freezing temperature. Clogged refrigerant path will reduce flow of refrigerant, lubrication oil, and cause compressor overheating.

Air conditioners that are completely installed at site will have filter dryer, and sight glass attached. Hence presence of moisture within the system can be detected by formation of moisture at the sight glass.

However, there are air conditioners that are hermetically sealed at the manufacturer’s factory. These units will not have sight glass installed. Examples of hermetically sealed units are window air conditioners and portable air conditioners.

A way to check this is by checking if there is any leak within the system. If there is no leak, then there should be no problem.

Otherwise, repairs need to be carried out, and the system has to be re-sealed hermetically by the manufacturer, or a contractor.

Simple leak detection

Leak of air conditioner tubes will pose the threat of refrigerant loss and finally, no cooling or heating.

There are three famous simple leak detection methods at end user level. They are-

- Soap test

- Electronic leak detector, and,

- UV light test

Electronic leak detector is most widely used and very accurate refrigerant leak testing method.

It is also known as the halogen leak detector, as refrigerant used in air conditioners are of chlorine and fluorine based material.

Working system:

- Leaking refrigerant will be drawn into the unit by a small pump.

- The refrigerant will pass through a proportional halogen detector, and it will be translated into electrical signal.

- This signal will be amplified and read out will be provided, together with audible sound.

Testing steps are,

- switch on the unit,

- cover the test area from direct draft,

- pass the detection probe near test area and wait for audible and visible signals

Simple fan, blower diagnostic

Please turn off ALL electrical supply to the system before performing this.

Diagnostic for fans and blowers include spinning these, and listening to metal rubbing, or any rough noise.

Feel, if it takes extra effort to spin these. A “rough” feel indicates improper lubrication, or bearing wear.

These problems can be treated by wiping off the previous grease/oil on the motor shaft, and applying with new grease/oil.

If the problems still persist, then bearing replacement is required.

Air conditioning maintenance by trained personnel:

These air conditioning maintenance activities may be carried out at the user level, but

- Possibility of air conditioner system failure is higher,

- Some would violate the law, especially for handling refrigerant.

All maintenance with regard major refrigerant handling has only been approved to Environmental Protection Agency (EPA) certified persons.

However, there are possible checks that user can perform before identifying the need for servicing.

Some of the checks will only release a very minimal amount of refrigerant into the atmosphere, and do not violate the law

- Possibility of injury from electrocution is also high, if necessary precautions are not taken

Specialized air conditioning maintenance consists of,

- Refrigerant superheat or sub cooling check,

- Refrigerant leak detection – skilled,

- Refrigerant charging,

- System pump down

Recommendation

- Emerson network power, a division of Emerson is a global company matching technology and design to supply innovative solutions for its customers benefit.

- Emerson network power is leader in the “business critical continuity” field thanks to its products and services.

- Precision cooling is a key requirement to ensure safe working conditions to datacenters, computer rooms, and other equipment simultaneously needing a high sensible heat discharge and a precise temperature and humidity control

- Flexible solutions and low running costs add value to the IT facility.

- Products have been especially designed to achieve top reliability. All components have been sized for the lowest possible stress. Models have been rigorously tested before being launched on the market.

- The iCOM (intelligent communication and monitoring) control device handles the operation of the HPM (High Performance Monitoring) units.

- EC (Electronically Commutated) fans used in the PAC unit which save 40% power

Digital Scroll compressor is used in PAC unit which contains better room control, energy saving with partial load, quick adjustment to load changes, simple and reliable, frequency converter and EMC free.

Conclusion

This is the age of science and communication is being developing day by day. For that we need to use a lot of machineries. Every operation of our company depends upon the instant around-the-clock availability of computers, servers and other electronic systems. If they aren’t working, neither is our company.

Unfortunately, every piece of this equipment of our company possesses produces heat. And if we don’t get rid of the heat, we are going to have problems.

Precision air systems often feature greater internal redundancy of components than comfort cooling systems, allowing them to continue operating in the event of some failures. In addition, they are supported by factory-trained, locally-based installation, service and support partners that are accustomed to the needs and sensitivities of working in the data center environment. Depending upon the manufacturer, 24-hour emergency service and preventive maintenance service may be available on precision cooling systems.

Because even a short amount of downtime can impact the bottom line, leading precision air systems are designed for serviceability.

Computer systems have unique environ-mental requirements and necessitate cooling systems that match those requirements. Comfort cooling systems are appropriate for “comfort” environments – facilities that are occupied by people or that house routine equipment and supplies. Precision cooling systems provide the efficiency, reliability and flexibility to meet the increasing demands for heat rejection, humidity control, filtration, and other requirements in data centers and other high availability computer facilities.