Dissolved Gas Analysis (DGA) is a diagnostic technique used in electrical power systems to evaluate the condition of insulating materials found in high-voltage equipment such as transformers and circuit breakers. It is an investigation into electrical transformer oil pollutants. It entails the monitoring and analysis of gases dissolved in insulating oil within the apparatus. Insulating materials in electrical equipment emit gasses as they gradually degrade over time.

The content and distribution of these dissolved gases provide information about the impacts of deterioration, such as pyrolysis or partial discharge, while the rate of gas creation reflects the severity. DGA is helpful in a preventive maintenance program. Gas collection and analysis in an oil-insulated transformer was first described in 1928. As of 2018, several years of empirical and theoretical research have gone into analyzing transformer fault gasses.

The breakdown of insulating materials, as well as the presence of electrical faults inside the device, might result in gas production. These gasses dissolve in the insulating oil, and their composition can provide useful information about the equipment’s state. The most common gases analyzed in DGA include hydrogen (H2), methane (CH4), ethane (C2H6), ethylene (C2H4), acetylene (C2H2), carbon monoxide (CO), carbon dioxide (CO2), and oxygen (O2).

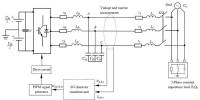

DGA normally involves sampling the oil and submitting it to a laboratory for analysis. Mobile DGA devices can be carried and utilized on-site, and some can be connected directly to a transformer. Online monitoring of electrical equipment is an essential component of the smart grid.

Each gas has precise ratios and concentrations that correspond to various types of defects or situations in the equipment. For example, large quantities of acetylene and ethylene can signal thermal problems such as overheating or partial discharge, but high levels of hydrogen and methane may indicate electrical arcing.

DGA is normally carried out by extracting a sample of insulating oil from the device and studying it with techniques such as gas chromatography or photoacoustic spectroscopy. Interpreting DGA results demands expertise to correlate gas concentrations with certain types of defects and determine the severity of the situation.

DGA testing regularly is an essential component of high-voltage electrical equipment condition monitoring and predictive maintenance plans. Early detection of probable problems with DGA can assist avert catastrophic failures, optimize maintenance schedules, and extend equipment life.