Desalination of industrial wastewater is an important step in water treatment and conservation. While traditional desalination methods such as reverse osmosis (RO) and thermal distillation are widely used, they can be inefficient and expensive. However, several innovative and sustainable methods of wastewater desalination are emerging.

Engineers are working on a cutting-edge process that will reduce the amount of energy used and the cost of water desalination. Researchers at Vanderbilt University are part of a team that has developed a cutting-edge method for removing salt from hypersaline industrial wastewater that is both energy-efficient and cost-effective.

While reverse osmosis desalination has made great strides, allowing for salt removal from seawater for less than a penny per gallon, it still falls short of eliminating saline in wastewater from industries such as mining, oil and gas, and power generation, as well as inland brackish water. Currently, industrial brines are injected into deep geological formations or transferred to evaporation ponds, and both disposal methods face increased regulatory and environmental challenges.

The elimination of evaporation is the key to developing potentially energy-efficient brine crystallization processes.

Shihong Lin

Zero liquid discharge and minimal liquid discharge, which use engineered treatment systems to eliminate brines or reduce brine volume, are already required in some countries for certain industries and are expected to become more widely adopted in the near future. Current ZLD/MLD treatments typically use a technology known as mechanical vapor compression, which uses heat generated by electricity to evaporate brines until only salt remains. Many users cannot afford these processes due to the high capital and operating costs of MVC.

Shihong Lin, associate professor of civil and environmental engineering and 2023 Chancellor Faculty Fellow, and his team, which includes Colorado State University researchers, believe they have a solution to this quandary.

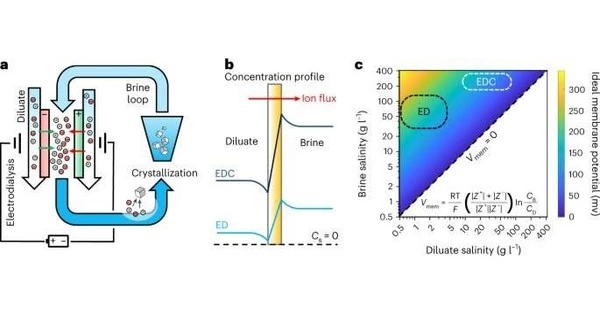

Lin and his colleagues describe electrodialytic crystallization, a novel brine treatment technology that has the potential to reduce the energy consumption and cost of brine crystallization, in a paper featured on the cover of the June 2023 issue of the journal Nature Water. According to the researchers, the fundamental principle of EDC is similar to electrodialysis, a process that has been used in various industries for desalination and brine concentration.

An electric field is used to pull ions through ion exchange membranes in ED. ED can produce streams of deionized water and streams of concentrated brine by arranging various types of IEMs in a specific pattern. According to the researchers, with some configuration changes to that process, EDC keeps the brine within the integrated system and uses an electric field to induce salt crystallization without the use of costly evaporation methods.

“The elimination of evaporation is the key to developing potentially energy efficient brine crystallization processes,” the paper claims.

One significant technical challenge is that certain ions drag too much water across the IEMs, reducing the process’s effectiveness in concentrating the brine stream. This phenomenon, known as electro-osmosis, prevents some salts from crystallizing out completely. According to the researchers, better membrane design and optimized operation could potentially address this issue and make EDC more widely applicable.

Nonetheless, for the salts that EDC can handle, preliminary analysis revealed that EDC combined with reverse osmosis can potentially consume much less energy than MVC for brine crystallization.