Electrorheological fluids (ER) are suspensions of extremely small nonconducting yet electrically active particles (up to 50 micrometers in diameter) in an electrically insulating fluid. A type of smart material alters its rheological (flow) properties significantly in response to an applied electric field. In reaction to an electric field, the apparent viscosity of these fluids changes reversibly by an order of up to 100,000. These fluids are made up of micron-sized solid particles suspended in a liquid or polymer matrix.

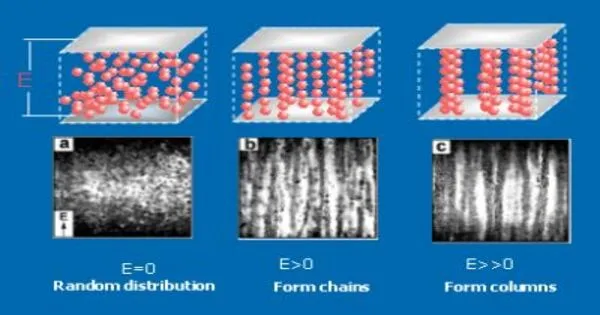

When an electric field is added to the ER fluid, the particles align along the field lines, causing the fluid to become more viscous or solid-like. The fluid returns to its original, more liquid-like state when the electric field is removed. A typical ER fluid, for example, can transition from a liquid to a gel and back, with response times on the order of milliseconds. The phenomenon is frequently referred to as the Winslow effect after its discoverer, Willis Winslow, an American inventor who secured a US patent on the effect in 1947 and published a paper on it in 1949.

Key characteristics and properties of Electrorheological fluids include:

- Field-Dependent Viscosity: ER fluids are known for their ability to rapidly change from a free-flowing liquid to a near-solid or highly viscous state when subjected to an electric field. This property can be controlled and adjusted by varying the strength of the electric field.

- Reversibility: The transformation of ER fluids is typically reversible. When the electric field is turned off, the particles disperse randomly, and the fluid regains its original flow properties.

- Response Time: ER fluids can respond very quickly to changes in the electric field, often within milliseconds. This rapid response makes them suitable for real-time applications.

- Composition: ER fluids can be composed of various materials. Commonly used particles include silica, polymers, or even magnetizable materials like iron particles. The choice of particle material and size affects the fluid’s rheological behavior.

Applications

ER fluids have been used in a variety of technical disciplines, including the automotive and aerospace industries. Vibration dampening in automobile suspensions, haptic feedback in consumer electronics, and even as a component in adaptive constructions and robotics are all possible applications.

In short, electrorheological fluids are smart materials that, when exposed to an electric field, can shift from a liquid to a solid or very viscous state. Their distinct rheological qualities have led to a wide range of applications in engineering and industry, particularly where quick and reversible changes in material properties are required.