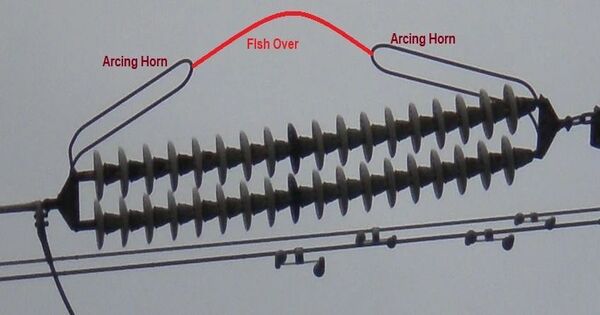

Arcing horns (also known as arc-horns) are projecting conductors that shield insulators or switch hardware in high-voltage electric power transmission lines from damage during a flashover. Overvoltages on transmission lines caused by atmospheric electricity, lightning strikes, or electrical faults can generate arcs over insulators (flashovers) and destroy them. Alternatively, atmospheric circumstances or transients might induce an arc to form in a switch’s breaking path while it is in operation.

Arcing horns allow flashover to occur by bypassing the shielded device’s surface. Horns are typically paired on opposite side of an insulator, one connected to the high voltage section and the other to ground, or at the break point of a switch contact. They are commonly seen on insulator strings on overhead lines or as protective bushings for transformers. Horns might be simple cylindrical rods, circular guard rings, or contoured curves known as ‘stirrups’.

Operation

Arcing horns create a spark gap across the insulator with a lower breakdown voltage than the air path along the insulator surface, thus an overvoltage causes the air to breakdown and an arc to form between the arcing horns, diverting the current away from the insulator’s surface. An arc between the horns is more bearable to the equipment, giving it more time to notice the malfunction and safely clear the arc using remote circuit breakers.

The geometry of some designs causes the arc to move away from the insulator, aided by rising currents as it heats the surrounding air. As the path length rises, the arc cools, the electric field decreases, and the arc extinguishes when it can no longer bridge the gap. Other designs can use the magnetic field generated by the high current to move the arc away from the insulator. This setup is commonly referred to as a magnetic blowout.

Arcing horns may be treated as sacrificial equipment by design criteria and maintenance regimes, as they are less expensive and easier to repair than the insulator, whose failure can result in the entire destruction of the equipment they insulate. If insulator strings on overhead lines fail, the line may split, posing substantial safety and cost risks.

Thus, arcing horns contribute to the insulation coordination process, which involves associating system protection with protective device features. Among other qualities, the horns should have near-infinite impedance during normal working conditions to reduce conductive current losses, low impedance during the flashover, and physical resistance to the arc’s high temperature.