Shear reinforcement design:

Vs = Vu – φVc

= 40.84 – (2 * 0.85√3500 * 10 * 16) / 1000 = 24.78 kip

4 √fc bw d = (4√3500 * 10 * 16) / 1000 = 32.183 kip

Vs < 4√fc bw d So, ok

Stirrup spacing:

1) Smax = Avfy / 50 bw = (2 * 0.11 * 60000) / 50 * 10 = 26.40”

2) Smax = d / 2 = 16 / 2 = 8”

3) Smax = 24”

4) S = φ Avfy d / Vs= 0.85 * 2 * 0.11 * 60000 * 16 / (24.78 * 1000) = 7.24”

Use stirrups # 3 bar @ 7” c/c

Design of the beam: B13, B15, B16, B18, B19, B21, B22, B24 (at 4th story)

From load combination:

Maximum moment at end section

Negative moment = 64.59 k – ft

Mu = ф ρfy bd² (1- 0.59 ρfy / f’c)

d² = Mu / (фρfy bd (1- 0.59 ρf / f’c)

ρ max = 0.75 ρb, ρb = 0.85 β1 f’c / fy * 87000 / (87000 + 60000)

= 0.85 * 0.85 * 3.5 / 60 * 87000 / (87000 + 60000) = 0.02494

ρ max = 0.75 * 0.02494 = 0.0187

d² = 64.59 * 12 / 0.90 * 0.0187 * 60 * 10 (1-0.59 * 0.0187 * 60 / 3.50)

d = 9.72, Clear cover = 2”, Total depth = 9.72 + 2= 11.72. Say, d = 12”

Provided Beam size = 12” * 10”, d = 12”- 2”= 10”

Main steel calculation:

As = Mu / φfy (d – a / 2)

= 64.59 * 12 / 0.90 * 60 (10 – 1 / 2) = 1.51 in², a = Asfy / 0.85f’c bw

a = 1.51 * 60 / 0.85 * 3.50 * 10 = 3.045

As = 64.59 * 12 / 0.90 * 60 (10 – 3.045 / 2) = 1.693 in²

a = 1.693 * 60 / 0.85 * 3.5 * 10 = 3.414 in.

As = 64.59 * 12 / 0.90 * 60 (10 – 3.414 / 2) = 1.73 in². Use – 2 # 7 +2 # 5 bars

Main steel calculation:

Mid section:

As = Mu / φfy (d – a / 2)

= 51.98 * 12 / 0.90 * 60 (10 – 1 / 2) = 1.215 in², a = Asfy / 0.85f’c bw

a = 1.215 * 60 / 0.85 * 3.50 * 10 = 2.450 in.

As = 51.98 * 12 / 0.90 * 60 (10 – 2.45 / 2) = 1.316 in²

a = 1.316 * 60 / 0.85 * 3.50 * 10 = 2.609 in.

As = 51.98 * 12 / 0.90 * 60 (10 – 2.609 / 2) = 1.328 in². Use – 2 # 6 +2 # 5 bars

Shear reinforcement design:

Vs = Vu – φVc

= 25.40 – (2 * 0.85√3500 * 10 * 10) / 1000 = 15.34 kip

4 √fc bw d = (4√3500 * 10 * 10) / 1000 = 23.66 kip

Vs < 4√fc bw d So, ok

Stirrup spacing:

1) Smax = Avfy / 50 bw = (2 * 0.11 * 60000) / 50 * 10 = 26.40”

2) Smax = d / 2 = 10 / 2 = 5”

3) Smax = 24”

4) S = φ Avfy d / Vs = 0.85 * 2 * 0.11 * 60000 * 10 / (15.34*1000) = 7.31 ”

Use stirrups # 3 bar @ 5” c/c

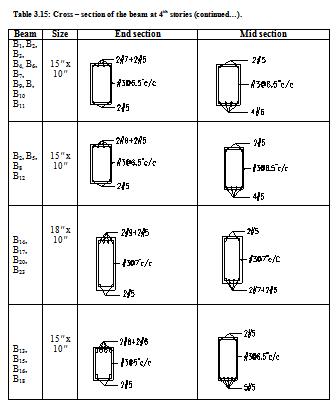

Design of the beam: B1, B3,B4, B6, B7, B9, B10, B11 ( at 4th story )

From load combination:

Maximum moment:

End section:

Negative moment = 87.25 k – ft

Mu = ф ρfy bd² (1- 0.59 ρfy / fc)

d² = Mu/ фρfy bd (1- 0.59 ρfy / fc)

ρ max = 0 .75 ρb, ρb = 0.85 β1 f’c / fy * 87000 / (87000 + 60000)

= 0.85 * 0.85 * 3.5 / 60 * 87000 / (87000 + 60000) = 0.02494

ρ max = 0.75 * 0.02494 = 0.0187

d² = 87.25 * 12 / 0.90 * 0.0187 * 60 * 10 (1- 0.59 * 0.0187 * 60 / 3.50)

d = 11.29, Clear cover = 2”, Total depth = 11.29 + 2= 13.29. Say, d = 15”

Provided Beam size = 15” * 10”, d = 15”- 2”= 13”

Main steel calculation:

As = Mu / φfy (d – a / 2)

= 87.25 * 12 / 0.90 * 60 (13 – 1 / 2) = 1.551 in², a = Asfy / 0.85fc bw

a = 1.551 * 60 / 0.85 * 3.50 * 10 = 3.128 in.

As = 87.25 * 12/0.90 * 60 (13 – 3.128 / 2) = 1.695 in²

a = 1.695 * 60 / 0.85 * 3.50 * 10= 3.418 in.

As = 87.25 * 12 / 0.90 * 60 (10 – 3.418 / 2) = 1.717 in². Use – 2 # 7 + 2 # 5 bars

Main steel calculation:

Mid section:

As = Mu / φfy (d – a / 2)

= 35.0 * 12 / 0.90 * 60 (13 – 1 / 2) = 0.622 in², a = Asfy / 0.85f’c bw

a = 0.622 * 60 / 0.85 * 3.50 * 10 = 1.254 in.

As = 35.00 * 12 / 0.90 * 60 (13 – 1.254 / 2) = 0.628 in²

a = 0.628 * 60 / 0.85 * 3.50 * 10 = 1.266 in.

As = 35.0 * 12 / 0.90 * 60 (13 – 1.266/2) = 0.63 in². Use – 2 # 6 bars

Shear reinforcement design:

Vs = Vu – φVc

= 22.23 – (2 * 0.85√3500 * 10 * 13) / 1000 = 9.15 kip

4 √fc bw d = (4√3500 * 10 * 13) /1000 = 30.76 kip

Vs < 4√fc bw d So, ok

Stirrup spacing:

1) Smax = Avfy / 50 bw = (2 * 0.11* 60000) / 50 * 10 = 26.40”

2) Smax = d / 2 = 13 / 2 = 6½”

3) Sma = 24”

4) S = φ Avfy d / Vs = 0.85 * 2 * 0.11 * 60000 * 13 / (9.15 * 1000) = 15.94”

Use stirrups # 3 bar @ 6½” c/c

Design of the beam: B2, B5, B8, B12 ( at 4th story )

From load combination:

Maximum moment:

End section:

Negative moment = 108.93 k-ft

Mu = ф ρfy bd² (1- 0.59 ρfy / fc)

d² = Mu / фρfy bd (1- 0.59 ρfy / fc)

ρ max = 0.75 ρb, ρb = 0.85 β1 fc / fy * 87000 / (87000 + 60000)

= 0.85 * 0.85 * 3.5 / 60 * 87000 / (87000 + 60000) = 0.02494

ρ max = 0.75 * 0.02494 = 0.0187

d² = 108.93 * 12 / 0.90 * 0.0187 * 60 * 10(1- 0.59 * 0.0187 * 60 / 3.50)

d = 12.63, Clear cover = 2”, Total depth = 12.63 + 2 = 14.63. Say, d = 15”

Provided Beam size = 15” * 10”, d = 15”- 2”= 13”

Main steel calculation:

As = Mu / φfy (d – a / 2)

= 108.93 * 12 / 0.90 * 60 (13 – 1 / 2) = 1.936 in², a = Asfy / 0.85fc bw,

a = 1.936 * 60 / 0.85 * 3.50 * 10 = 3.904 in.

As = 108.93 * 12 / 0.90 * 60 (13 – 3.904 / 2) = 1.867 in²

a = 1.897 * 60 / 0.85 * 3.50 * 10 = 3.765 in.

As = 108.93 * 12 / 0.90 * 60 (13 – 3.765 / 2) = 2.177 in². Use – 2 # 8 +2 # 5 bars

Main steel calculation:

Mid section:

As = Mu / φfy (d – a / 2)

= 59.56 * 12 / 0.90 * 60 (13 – 1 / 2) = 1.058 in², a = Asfy / 0.85fc bw,

a = 1.058 * 60 / 0.85 * 3.50 * 10 = 2.133 in.

As = 59.56 * 12 / 0.90 * 60 (13 – 2.133 / 2) = 1.108 in²

a = 1.108 * 60 / 0.85 * 3.5 * 10 = 2.234 in.

As = 59.56 * 12 / 0.90 * 60 (13 – 2.234 / 2) = 1.113in². Use – 4 # 5 bars

Shear reinforcement design:

Vs = Vu – φVc

= 26.90 – (2 * 0.85√3500 * 10 * 13) / 1000 = 13.825 kip

4 √fc bw d = (4√3500 * 10 * 13) / 1000 = 30.763 kip

Vs < 4√fc bw d So, ok

Stirrups Spacing:

1) Smax = Avfy / 50 bw = (2 * 0.11 * 60000) / 50 * 10 = 26.40”

2) Smax = d / 2 = 13 / 2 = 6½”

3) Smax = 24”

4) S = φ Avfyd / Vs = 0.85 * 2 * 0.11 * 60000 * 13 / (13.825 * 1000) = 10.55”

Use stirrups # 3 bar @ 6½” c/c

Design of the beam: B14, B17, B20, B23 (at 4th story)

From load combination:

Maximum Moment:

End section:

Negative moment = 164.32 k-ft

Mu = ф ρfy bd² (1 – 0.59 ρfy / fc)

d² = Mu / (ф ρfy bd (1- 0.59 ρfy / fc)

ρ max = 0.75 ρb, ρb = 0.85 β1 fc / fy * 87000 / (87000 + 60000)

= 0.85 * 0.85 * 3.5 / 60 * 87000 / (87000 + 60000) = 0.02494

ρmax = 0.75 * 0.02494 = 0.0187

d² = 164.32 *12 / 0.90 * 0.0187 * 60 * 12 (1 – 0.59 * 0.0187 * 60 / 3.50)

d = 14.16, Clear cover = 2”, Total depth = 14.16 + 2 = 16.16. Say, d = 18”

Provided Beam size = 18” * 10”, d = 18”- 2”= 16”

Main steel calculation:

As = Mu / φfy (d – a / 2)

= 164.32 * 1 / 0.90 * 60 (16 – 1 / 2) = 2.355 in², a = Asfy / 0.85fc bw,

a = 2.355 * 60 / 0.85 * 3.50 * 12 = 3.957 in.

As = 164.32 * 12 / 0.90 * 60 (16 – 3.597 / 2) = 2.604 in²

a = 2.604 * 60 / 0.85 * 3.50 * 10 = 4.376 in.

As = 164.32 * 12 / 0.90 * 60 (16 – 4.376 / 2) = 2.643 in². Use – 2 # 9 +2 # 5 bars

Main steel calculation:

Mid section:

As = Mu / φfy (d – a / 2)

= 103.66 * 12 / 0.90 * 60 (16 – 1 / 2) = 1.49 in², a = Asfy / 0.85fc bw,

a = 1.49 * 60 / 0.85 * 3.5 * 10 = 3.00 in.

As = 103.66 * 12 / 0.90 * 60 (16 – 3.00 / 2) = 1.59 in²

a = 1.59 * 60 / 0.85 * 3.50 * 10 = 3.206 in.

As = 103.66 * 12 / 0.90 * 60 (16 – 3.206 / 2) = 1.60 in². Use – 2 # 7 +2 # 5 bars

Shear reinforcement design:

Vs = Vu – φVc

= 43.60 – (2 * 0.85√3500 * 10 * 16) / 1000 = 24.28 kip

4 √fc bw d = (4√3500 * 12 * 16) / 1000 = 45.435 kip

Vs < 4√fc bw d So, ok

Stirrup spacing:

1) Smax = Avfy / 50 bw = (2 * 0.11 * 60000) / 50 * 10 = 26.40”

2) Smax = d / 2 = 16 / 2 = 8”

3) Smax = 24”

4) S = φAvfy d / Vs = 0.85 * 2 * .11 * 60000 * 16 / (24.28 * 1000) = 7.39 ”

Use stirrups # 3 bar @ 7” c/c

Design of the beam: B13, B15, B16, B18, B19, B21, B22, B24 (at 4th story)

From load combination:

Maximum moment at end section

Negative moment = 115.36 k – ft

Mu = ф ρfy bd² (1- 0.59 ρfy / fc)

d² = Mu / (ф ρfy bd (1- 0.59 ρf / fc)

ρ max = 0.75 ρb, ρb = 0.85 β1 fc / fy * 87000 / (87000 + 60000)

= 0.85 * 0.85 * 3.5 / 60 * 87000 / (87000 + 60000) = 0.02494

ρ max = 0.75 * 0.02494 = 0.0187

d² = 115.36 * 12 / 0.90 * 0.0187 * 60 * 10 (1 – 0.59 * 0.0187 * 60 / 3.50)

d = 13.0, Clear cover = 2”, Total depth = 13 + 2 = 15.0. Say, d = 15”

Provided Beam size = 15” * 10”, d = 15”- 2”= 13”

Main steel calculation:

As = Mu / φfy (d – a / 2)

= 115.36 * 12 / 0.90 * 60 (13 – 1 / 2) = 2.05 in², a = Asfy / 0.85fc bw.

a = 2.05 * 60 / 0.85 * 3.50 * 10 = 4.134 in

As = 115.36 * 12 / 0.90 * 60 (13 – 4.134 / 2) = 2.344 in²

a = 2.344 * 60 / 0.85 * 3.5 * 10 = 4.727 in.

As = 115.36 * 12 / 0.90 * 60 (13 – 4.727 / 2) = 2.41 in². Use – 2 # 8 +2 # 6 bars

Main steel calculation:

Mid section:

As = Mu / φfy (d – a / 2)

= 48.69 * 12 / 0.90 * 60 (13 – 1 / 2) = 0.865 in², a = Asfy / 0.85fc bw,

a = 0.865 * 60 / 0.85 * 3.50 * 10 = 1.744 in

As = 48.69 * 12 / 0.90 * 60 (13-1.744/2) = 0.892 in²

a = 0.892 * 60 / 0.85 * 3.50 * 10 = 1.798 in.

As = 48.69 * 12 / 0.90 * 60 (13 – 1.798 / 2) = 0.894 in². Use – 3 # 5 bars

Shear reinforcement design:

Vs = Vu – φVc

= 32.18 – (2 * 0.85√3500 * 10 * 13) / 1000 = 19.10 kip

4 √fc bw d = (4√3500 * 10 * 13) / 1000 = 30.763kip

Vs < 4√fc bw d So, ok

Stirrup spacing:

1) Smax = Avfy / 50 bw = (2 * 0.11 * 60000) / 50 * 10 = 26.40”

2) Smax = d / 2 = 13 / 2 = 6½”

3) Smax = 24”

4) S = φ Avfy d / Vs = 0.85 * 2 * .11 * 60000 * 13 / (19.10 * 1000) = 7½ ”

Use stirrups # 3 bar @ 6½” c/c

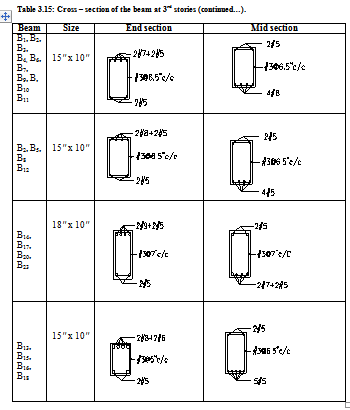

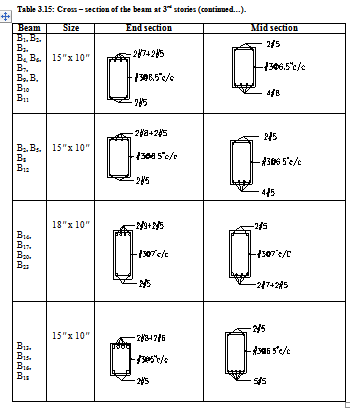

Design of the beam: B1, B3, B4, B6, B7, B9, B10, B11 ( at 3rd story )

From load combination:

Maximum moment:

End section:

Negative moment = 87.25 k-ft

Mu = ф ρfy bd² (1- 0.59 ρfy / fc)

d² = Mu / фρfy bd (1- 0.59 ρfy / fc)

ρ max = 0.75 ρb, ρb = 0.85 β1 fc / fy * 87000 / (87000 + 60000)

= 0.85 * 0.85 * 3.50 / 60 * 87000 / (87000 + 60000) = 0.02494

ρmax = 0.75 * 0.02494 = 0.0187

d² = 87.25 * 12 / 0.90 * 0.0187 * 60 * 10 (1 – 0.59 * 0.0187 * 60 / 3.50)

d = 11.29, Clear cover = 2”, Total depth = 11.29+2 = 13.29. Say, d = 15”

Provided Beam size = 15” * 10”, d = 15”- 2”= 13”

Main steel calculation:

As = Mu / φfy (d – a / 2)

= 87.25 * 12 / 0.90 * 60 (13 – 1 / 2) = 1.551 in², a = Asfy / 0.85fc bw,

a = 1.551 * 60 / 0.85 * 3.50 * 10 = 3.128 in.

As = 87.25 * 12 / 0.90 * 060 (13 – 3.128 / 2) = 1.695 in²

a = 1.695 * 60 / 0.85 * 3.5 * 10 = 3.418 in.

As = 87.25 * 12 / 0.90 * 60 (10 – 3.418 / 2) = 1.717 in². Use – 2 # 7 +2 # 5 bars

Main steel calculation:

Mid section:

As = Mu / φfy (d – a / 2)

= 35.0 * 12 / 0.90 * 60 (13 – 1 / 2) = 0.622 in², a = Asfy / 0.85f’c bw

a = 0.622 * 60 / 0.85 * 3.50 * 10 = 1.254 in.

As = 35.00 * 12 / 0.90 * 60 (13 – 1.254 / 2) = 0.628 in²

a = 0.628 * 60 / 0.85 * 3.50 * 10 = 1.266 in.

As = 35.0 * 2 / 0.90 * 60 (13 – 1.266 / 2) = 0.63 in². Use – 2 # 6 bars

Shear reinforcement design:

Vs = Vu – φVc

= 22.23 – (2 * 0.85√3500 * 10 * 13) / 1000 = 9.15 kip

4 √fc bw d = (4√3500 * 10 * 13) / 1000 = 30.76 kip

Vs < 4√fc bw d So, ok

Stirrup spacing:

1) Smax = Avfy / 50 bw = (2 * 0.11 * 60000) / 50 * 10 = 26.40”

2) Smax = d / 2 = 13 / 2 = 6½”

3) Smax = 24”

4) S = φ Avfyd / Vs = 0.85 * 2 * 0.11 * 60000 * 13 / (9.15 * 1000) =15.94

Use stirrups # 3 bar @ 6½” c/c

Design of the beam: B2, B5, B8, B12 ( at 3rd story )

From load combination:

Maximum moment at end section

Negative moment = 108.93 k-ft

Mu = ф ρfy bd² (1 – 0.59 ρfy / fc)

d² = Mu / фρfy bd (1- 0.59 ρfy / fc)

ρ max = 0.75 ρb, ρb = 0.85 β1 fc / fy * 87000 / (87000 + 60000)

= 0.85 * 0.85 * 3.5 / 60 * 87000 / (87000 + 60000) = 0.02494

ρ max = 0.75 * 0.02494 = 0.0187

d² = 108.93 * 12 / 0.90 * 0.0187 * 60 * 10 (1 – 0.59 * 0.0187 * 60 / 3.50)

d = 12.63, Clear cover = 2”, Total depth = 12.63+2= 14.63. Say, d = 15

Provided Beam size = 15” * 10”, d = 15”- 2”= 13”

Main steel calculation:

As = Mu / φfy (d – a / 2)

= 108.93 * 12 / 0.90 * 60 (13 – 1 / 2) = 1.936 in², a = Asfy / 0.85fc bw.

a = 1.936 * 60 / 0.85 * 3.50 * 10 = 3.904 in.

As = 108.93 * 12 / 0.90 * 60 (13 – 3.904 / 2) = 1.867 in²

a = 1.897 * 60 / 0.85 * 3.5 * 10 = 3.765 in

As = 108.93 * 12 / 0.90 * 60 (13-3.765 / 2) = 2.177 in². Use – 2 # 8 +2 # 5 bars

Main steel calculation:

Mid section:

As = Mu / φfy (d – a / 2)

= 59.56 * 12 / 0.90 * 60 (13 – 1 / 2) = 1.058 in², a = Asfy / 0.85fc bw

a = 1.058 * 60 / 0.85 * 3.5 * 10 = 2.133 in.

As = 59.56 * 12 / 0.90 * 60 (13 – 2.133 / 2) = 1.108 in²

a = 1.108 * 60 / 0.85 * 3.50 * 10 = 2.234 in.

As = 59.56 * 10.90 * 6 (13 – 2.234 / 2) = 1.113in². Use – 4 # 5 bars

Shear reinforcement design:

Vs = Vu – φVc

= 26.90 – (2 * 0.85√3500 * 10 * 13) / 1000 = 13.825 kip

4 √fc bw d = (4√3500 * 10 * 13) / 1000 = 30.763 kip

Vs < 4√fc bw d. So, ok

Stirrup spacing:

1) Smax = Avfy / 50 bw = (2 * 0.11 * 60000) / 50 * 10 = 26.40”

2) Smax = d / 2 = 13 / 2 = 6½”

3) Smax = 24”

4) S = φ Avfyd / Vs = 0.85 * 2 * 0.11 * 60000 * 13 / (13.825 * 1000) = 10.55”

Use stirrups # 3 bar @ 6½” c/c

Design of the beam: B14, B17, B20, B23 ( at 3rd story )

From load combination:

Maximum moment at end section

Negative moment = 164.32 k-ft

Mu = ф ρfy bd² (1- 0.59 ρfy / fc)

d² = Mu / (фρfy bd (1- 0.59 ρfy / fc)

ρ max = 0.75 ρb, ρb = 0.85 β1 f’c / fy * 87000 / (87000 + 60000)

= 0.85 * 0.85 * 3.5 / 60 * 87000 / (87000 + 60000) = 0.02494

ρmax = 0.75 * 0.02494 = 0.0187

d² = 164.32 * 12 / 0.90 * 0.0187 * 60 * 12 (1-0.59 * 0.0187 * 60 / 3.50)

d = 14.16, Clear cover = 2”, Total depth = 14.16+2 = 16.16. Say, d = 18”

Provided Beam size = 18” * 10”, d = 18”- 2”= 16”

Main steel calculation:

As = Mu / φfy (d – a / 2)

= 164.32 * 12 / 0.90 * 60 (16 – 1 / 2) = 2.355 in², a = Asfy / 0.85fc bw

a = 2.355 * 60 / 0.85 * 3.50 * 12 = 3.957 in.

As = 164.32 * 12 / 0.90 * 60 (16 – 3.597 / 2) = 2.604 in²

a = 2.604 * 60 / 0.85 * 3.5 * 10 = 4.376 in.

As = 164.32 * 12 / 0.90 * 60 (16 – 4.376 / 2) = 2.643 in². Use – 2 # 9 +5 # 5 bars

Main steel calculation:

Mid section:

As = Mu / φfy (d – a / 2)

= 103.66 * 12 / 0.90 * 60 (16 – 1 / 2) = 1.49 in², a = Asfy / 0.85fc bw

a = 1.49 * 60 / 0.85 * 3.5 * 10 = 3.00 in.

As = 103.66 * 12 / 0.90 * 60 (16 – 3.00 / 2) = 1.59 in²

a = 1.59 * 60 / 0.85 * 3.50 * 10 = 3.206 in.

As = 103.66 * 12 / 0.90 * 60 (16 – 3.206 / 2) = 1.60 in². Use – 2 # 7 +2 # 5 bars

Shear reinforcement design:

Vs = Vu – φVc

= 43.60 – (2 * 0.85√3500 * 10 * 16) / 1000 = 24.28 kip

4 √fc bw d = (4√3500 * 12 * 16) / 1000 = 45.435 kip

Vs < 4√fc bw d So, ok

Stirrup spacing:

1) Smax = Avfy / 50 bw = (2 * 0.11 * 60000) / 50 * 10 = 26.40”

2) Smax = d / 2 = 16 / 2 = 8”

3) Smax = 24”

4) S = φ Avfy d / Vs = 0.85 * 2 * 0.11 * 60000 * 16 / (24.28 * 1000) = 7.39 in

Use stirrups # 3 bar @ 7” c/c

Design of the beam: B13, B15, B16, B18, B19, B21, B22, B24 (at 3rd story)

From load combination:

Maximum moment at end section

Negative moment = 115.36 k – ft

Mu = ф ρfy bd² (1- 0.59 ρfy / fc)

d² = Mu / (фρfy bd (1- 0.59 ρfy / f’c)

ρ max = 0.75 ρb, ρb = 0.85 β1 fc / fy * 87000 / (87000 + 60000)

= 0.85 * 0.85 * 3.5 / 60 * 87000 / (87000+60000) = 0.02494

ρ max = 0.75 * 0.02494 = 0.0187

d² = 115.36 * 12 / 0.90 * 0.0187 * 60 *10 (1- 0.59 * 0.0187 * 60 / 3.50)

d = 13.0, Clear cover = 2”, Total depth = 13+2 = 15.0. Say, d = 15”

Provided Beam size = 15” * 10”, d = 15”- 2”= 13”

Main steel calculation:

As = Mu / φfy (d – a / 2)

= 115.36 * 12 / 0.90 * 60 (13 – 1 / 2) = 2.05 in², a = Asfy / 0.85fc bw.

a = 2.05 * 60 / 0.85*3.5*10 = 4.134 in.

As = 115.36 * 12 / 0.90 * 60 (13 – 4.134 / 2) = 2.344 in.²

a = 2.344 * 60 / 0.85 * 3.5 * 10 = 4.727 in.

As = 115.36 * 12 / 0.90 * 60 (13 – 4.727 / 2) = 2.41 in². Use – 2 # 8 +2 # 6 bars

Main steel calculation:

Mid section:

As = Mu / φfy (d – a / 2)

= 48.69 * 12 / 0.90 * 60 (13 – 1 / 2) = 0.865 in², a = Asfy / 0.85fc bw,

a = 0.865 * 60 / 0.85 * 3.50 * 10 = 1.744 in.

As = 48.69 * 12 / 0.90 * 60 (13 – 1.744 / 2) = 0.892 in²

a = 0.892 * 60 / 0.85 * 3.5 * 10 = 1.798 in

As = 48.69 * 12/0.90 * 60 (13 – 1.798 / 2) = 0.894 in². Use – 3 # 5 bars

Shear reinforcement design:

Vs = Vu – φVc

= 32.18 – (2 * 0.85√3500 * 10 * 13) / 1000 = 19.10 kip

4 √fc bw d = (4√3500 *10 * 13) / 1000 = 30.763kip

Vs < 4√fc bw d So, ok

Stirrup spacing:

1) Smax = Avfy / 50 bw = (2 * 0.11 * 60000) / 50 * 10 = 26.40”

2) Smax = d / 2 = 13 / 2 = 6½”

3) Smax = 24”

4) S = φ Avfy d / Vs = 0.85 * 2 * .11 * 60000 * 13 / (19.10 * 1000) = 7½”

Use stirrups # 3 bar @ 6½” c/c

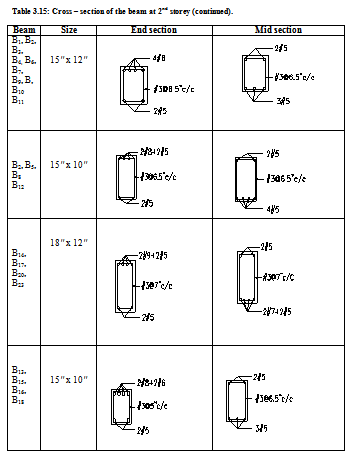

Design of the beam: B1, B3, B4, B6, B7, B9, B10, B11 ( at 2nd story )

From load combination:

Maximum moment at end section

Negative moment = 89.0 k – ft

Mu = ф ρfy bd² (1- 0.59 ρfy / fc)

d² = Mu / ф ρfy bd (1- 0.59 ρfy / fc)

ρ max = 0.75 ρb, ρb = 0.85 β1 fc / fy * 87000 / (87000 + 60000)

= 0.85 * 0.85 * 3.5 / 60 * 87000 / (87000 + 60000) = 0.02494

ρ max = 0.75 * 0.02494 = 0.0187

d² = 89.00 * 12 / 0.90 * 0.0187 * 60 * 12 (1 – 0.59 * 0.0187 * 60 / 3.50)

d = 10.42, Clear cover = 2”, Total depth = 10.42+2 = 12.42. Say, d = 15”

Provided Beam size = 15” * 12”, d = 15”- 2”= 13”

Main steel calculation:

As = Mu / φfy (d – a / 2)

= 89.00 * 12 / 0.90 * 60 (13 – 1 / 2) = 1.582 in², a = Asfy / 0.85fc bw

a = 1.582 * 60 / 0.85 * 3.50 * 12 = 2.658 in.

As = 89.0 * 12 / 0.90 * 60 (13 – 2.658 / 2) = 1.694 in²

a = 1.694 * 60 / 0.85 * 3.50 * 10 = 2.847 in.

As = 89.0 * 12 / 0.90 * 60 (13 – 2.847 / 2) = 1.708 in². Use – 4 # 6 bars

Main steel calculation:

Mid section:

As = Mu / φfy (d – a / 2)

= 42.26 * 12 / 0.90 * 60 (13 – 1 / 2) = 0.751 in², a = Asfy / 0.85fc bw

a = 0.751 * 60 / 0.85 * 3.50 * 10 = 1.514 in.

As = 42.26 * 12 / 0.90 * 60 (13 – 1.514 / 2) = 0 .767 in²

a = 0.767 * 60 / 0.85 * 3.50 * 10 = 1.546 in.

As = 42.26 * 12 / 0.90 * 60 (13 – 1.546 / 2) = 0.768 in². Use – 3 # 5 bars

Shear reinforcement design:

Vs = Vu – φVc

= 23.17 – (2 * 0.85√3500 * 10 * 13 / 1000 = 10.10 kip

4 √fc bw d = (4√3500 * 10 * 13) / 1000 = 30.76 kip

Vs < 4√fc bw d So, ok

Stirrup spacing:

1) Smax = Avfy/ 50 bw = (2 * 0.11 * 60000) / 50 * 10 = 26.40”

2) Smax = d / 2 = 13 / 2 = 6½”

3) Smax = 24”

4) S = φ Avfy d / Vs = 0.85 * 2 * 0.11 * 60000 * 13 / (10.10 * 1000) = 14.44”

Use stirrups # 3 bar @ 6½” c/c

Design of the beam: B2, B5, B8, B12 ( at 2nd story )

From load combination:

Maximum moment at end section

Negative moment = 114.44 k – ft

Mu = ф ρfy bd² (1- 0.59 ρfy / fc)

d² = Mu / ф ρfy bd (1- 0.59 ρfy / fc)

ρ max = 0.75 ρb, ρb = 0.85 β1 f’c / fy * 87000 / (87000 + 60000)

= 0.85 * 0.85 * 3.5 / 60 * 87000 / (87000 + 60000) = 0.02494

ρ max = 0.75 * 0.02494 = 0.0187.

d² = 114.44 * 12 / 0.90 * 0.0187 * 60 * 10 (1 – 0.59 * 0.0187 * 60 / 3.50).

d = 12.95, Clear cover = 2”, Total depth = 12.95+2 = 14.95. Say, d = 15”

Provided Beam size = 15” * 10”, d = 15”- 2”= 13”

Main steel calculation:

As = Mu / φfy (d – a / 2)

= 114.44 * 12 / 0.90 * 60 (13 – 1 / 2) = 2.034 in², a = Asfy / 0.85fc bw

a = 2.034 * 60 / 0.85 * 3.50 * 10 = 4.102 in.

As = 114.44 * 12 / 0.90 * 60 (13 – 4.102 / 2) = 2.322 in²

a = 2.322 * 60 / 0.85 * 3.50 * 10 = 4.683 in.

As = 114.44 * 12 / 0.90 * 60 (13 – 4.683 / 2) = 2.386 in². Use – 2 # 9 +2 # 5 bars

Main steel calculation:

Mid section:

As = Mu / φfy (d – a / 2)

= 60.52 * 12 / 0.90 * 60 (13 – 1 / 2) = 1.075 in², a = Asfy / 0.85fc bw

a = 1.075 * 60 / 0.85 * 3.50 * 10 = 2.168 in.

As = 60.52 * 12 / 0.90 * 60 (13 – 2.168 / 2) = 1.128 in²

a = 1.128 * 60 / 0.85 * 3.50 * 10 = 2.274 in.

As = 60.52 * 12 / 0.90 * 60 (13 – 2.274 / 2) = 1.133 in². Use – 4 # 5 bars

Shear reinforcement design:

Vs = Vu – φVc

= 24.47 – (2 * 0.85√3500 * 10 * 13) / 1000 = 17.412 kip

4 √fc bw d = (4√3500 * 10 * 13) / 1000 = 30.763 kip

Vs < 4√fc bw d So, ok

Stirrups Spacing:

1) Smax = Avfy / 50 bw = (2 * 0.11 * 60000) / 50 * 10 = 26.40”

2) Smax = d / 2 = 13 / 2 = 6½”

3) Smax = 24”

4) S = φ Avfy d / Vs = 0.85 * 2 * 0.11 * 60000 * 13 / (17.412 * 1000) = 8.37”

Use stirrups # 3 bar @ 6½” c/c

Design of the beam: B14, B17, B20, B23 ( at 2nd story )

From load combination:

Maximum moment at end section

Negative moment = 169.91 k-ft

Mu = ф ρfy bd² (1- 0.59 ρfy / fc)

d² = Mu / (ф ρfy bd (1- 0.59 ρfy / fc)

ρ max = 0.75 ρb, ρb = 0.85 β1 fc / fy * 87000 / (87000 + 60000)

= 0.85 * 0.85 * 3.5 / 60 * 87000 / (87000 + 60000) = 0.02494

ρ max = 0.75 * 0.02494 = 0.0187

d² = 169.91 * 12 / 0.90 * 0.0187 * 60 * 12 (1-0.59 * 0.0187 * 60 / 3.50)

d = 14.40, Clear cover = 2”, Total depth = 14.40+2 = 16.40. Say, d = 18”

Provided Beam size = 18” * 12”, d = 18”- 2”= 16”

Main steel calculation:

As = Mu / φfy (d – a / 2)

= 169.91 * 12 / 0.90 * 60 (16 – 1 / 2) = 2.43 in², a = Asfy / 0.85fc bw

a = 2.43 * 60 / 0.85 * 3.50 * 12 = 4.08 in.

As = 169.91*12 / 0.90 * 60 (16 – 4.08 / 2) = 2.70 in²

a = 2.70 * 60 / 0.85 * 3.50 * 12 = 4.54 in.

As = 169.91 * 12 / 0.90 * 60 (16 – 4.54 / 2 = 2.75 in². Use – 2 # 9 +2 # 6 bars

Main steel calculation:

Mid section:

As = Mu / φfy (d – a / 2)

= 104.10 *12 / 0.90 * 60 (16 – 1 / 2) = 1.49 in², a = Asfy / 0.85fc bw

a = 1.49 * 60 / 0.85 * 3.50 * 10 = 3.00 in.

As = 104.10 * 12 / 0.90 * 60 (16 – 3.00 / 2) = 1.59 in²

a = 1.59 * 60 / 0.85 * 3.50 * 10 = 3.206 in.

As = 104.10 * 12 / 0.90 * 60 (16 – 3.206 / 2) = 1.60 in². Use – 2 # 7 +2 # 5 bars

Shear reinforcement design:

Vs = Vu – φVc

= 44.19 – (2 * 0.85√3500 * 12 * 16) / 1000 = 24.88 kip

4 √fc bw d = (4√3500 * 12 * 16) / 1000 = 45.435 kip

Vs < 4√fc bw d So, ok

Stirrup spacing:

1) Smax = Avfy / 50 bw = (2 * 0.11 * 60000) / 50 * 10 = 26.40”

2) Smax = d / 2 = 16 / 2 = 8”

3) Smax = 24”

4) S = φAvfy d / Vs = 0.85 * 2 * 0.11 * 60000 * 16 / (24.88 * 1000) =7.21 ”

Use stirrups # 3 bar @ 7” c/c

Design of the beam: B13, B15, B16, B18, B19, B21, B22, B24 (at 2nd story)

From load combination:

Maximum moment at end section

Negative moment = 114.84 k-ft

Mu = ф ρfy bd² (1- 0.59 ρfy / fc)

d² = Mu / (фρfy bd (1- 0.59 ρfy / fc)

ρ max = 0.75 ρb, ρb = 0.85 β1 fc / fy * 87000 / (87000 + 60000)

= 0.85 * 0.85 * 3.5 / 60 * 87000 / (87000 + 60000) = 0.02494

ρ max = 0.75 * 0.02494 = 0.0187

d² = 114.84 *12 / 0.90 * 0.0187 * 60 * 10 (1 – 0.59 * 0.0187 * 60 / 3.50)

d = 12.97, Clear cover = 2”, Total depth = 12.97+2= 14.97

Say, d = 15”

Provided Beam size = 15” * 10”, d = 15”- 2”= 13”

Main steel calculation:

As = Mu / φfy (d – a / 2)

= 114.84 * 12 / 0.90 * 60 (13 – 1 / 2) = 2.041 in², a = Asfy / 0.85fc bw.

a = 2.041*60 / 0.85*3.5*10 = 4.116 in.

As = 114.84 * 12 / 0.90 * 60 (13 – 4.116 / 2) = 2.332 in²

a = 2.332 * 60 / 0.85 * 3.5 * 10 = 4.703 in.

As = 114.84 * 12 / 0.90 * 60 (13 – 4.703 / 2) = 2.396 in². Use – 2 # 8 +2 # 6 bars

Main steel calculation:

Mid section:

As = Mu / φfy (d – a / 2)

= 51.04 * 12 / 0.90 * 60 (13 – 1 / 2) = 0 .907 in², a = Asfy / 0.85fc bw,

a = 0.907 * 60 / 0.85 * 3.5 * 10 = 1.829 in.

As = 51.04 * 12 / 0.90 * 60 (13 – 1.829 / 2) = 0.938 in²

a = 0.938 * 60 / 0.85 * 3.50 *10 = 1.891 in.

As = 51.04 * 12 / 0.90 * 60 (13 – 1.891 / 2) = 0.941 in². Use – 3 # 5 bars

Shear reinforcement design:

Vs = Vu – φVc

= 32.71- (2 * 0.85√3500 * 10 * 13) / 1000 = 18.92 kip

4 √fc bw d = (4√3500 * 10 * 13) / 1000 = 30.763kip

Vs < 4√fc bw d So, ok

Stirrup spacing:

1) Smax = Avfy / 50 bw = (2 * 0.11 * 60000) / 50 * 10 = 26.40”

2) Smax = d / 2 = 13 / 2 = 6½”

3) Smax = 24”

4) S = φ Avfyd / Vs = 0.85 * 2 * 0.11 * 60000 * 13 / (18.92 * 1000) = 7.71”

Use stirrups # 3 bar @ 6½” c/c

Design of the beam: B1, B4, B6, B7, B9, B10, B11 ( at 1st story )

From load combination:

Maximum moment at end section

Negative moment = 89.0 k – ft

Mu = ф ρfy bd² (1 – 0.59 ρfy / fc)

d² = Mu / ф ρfy bd (1- 0.59 ρfy / fc)

ρ max = 0.75 ρb, ρb = 0.85 β1 f’c / fy * 87000 / (87000 + 60000)

= 0.85 * 0.85 * 3.5 / 60 * 87000 / (87000 + 60000) = 0.02494

ρ max = 0.75 * 0.02494 = 0.0187

d² = 89.00 * 12 / 0.90 * 0.0187 * 60 * 12 (1 – 0.59 * 0.0187 * 60 / 3.50)

d = 10.42, Clear cover = 2”, Total depth = 10.42+2 =12.42. Say, d = 15”

Provided Beam size = 15” * 12”, d = 15”- 2” = 13”

Main steel calculation:

As = Mu / φfy (d – a / 2)

= 89.00 * 12 / 0.90 * 60 (13 – 1 / 2) = 1.582 in², a = Asfy / 0.85fc bw.

a = 1.582 * 60 / 0.85 * 3.5 * 12 = 2.658 in.

As = 89.0 * 12 / 0.90 * 60 (13 – 2.658 / 2) = 1.694 in²

a = 1.694 * 60 / 0.85 * 3.50 * 10 = 2.847 in.

As = 89.0 * 12 / 0.90 * 60 (13 – 2.847 / 2) = 1.708 in². Use – 4 # 6 bars

Main steel calculation:

Mid section:

As = Mu / φfy (d – a / 2)

= 42.26 * 12 / 0.90 * 60 (13 – 1 / 2) = 0.751 in², a = Asfy / 0.85fc bw.

a = 0.751 * 60 / 0.85 * 3.5 * 10 = 1.514 in.

As = 42.26 * 12 / 0.90 * 60 (13 – 1.514 / 2) = 0.767 in²

a = 0.767 * 60 / 0.85 * 3.50 * 10 = 1.546 in

As = 42.26 * 12 / 0.90 * 60 (13 – 1.546 / 2) = 0.768 in². Use – 3 # 5 bars

Shear reinforcement design:

Vs = Vu – φVc

= 23.17 – (2 * 0.85√3500 * 10 * 13) / 1000 = 10.10 kip

4 √fc bw d = (4√3500 * 10 * 13) / 1000 = 30.76 kip

Vs < 4√fc bw d So, ok

Stirrup spacing:

1) Smax = Avfy / 50 bw= (2 * 0.11 * 60000 ) / 50 * 10 = 26.40”

2) Smax = d / 2 = 13 / 2 = 6½”

3) Smax = 24”

4) S = φAvfy d / Vs = 0.85 * 0.11 * 60000 * 13 / (10.10 * 1000) =14.44”

Use stirrups # 3 bar @ 6½” c/c

Design of the beam: B2, B5, B8, B12 ( at 1st story )

From load combination:

Maximum moment at end section

Negative moment = 114.44 k – ft

Mu = ф ρfy bd² (1 – 0.59 ρfy / fc)

d² = Mu / ф ρfy bd (1 – 0.59 ρfy / fc)

ρ max = 0.75 ρb , ρb = 0.85 β1 fc / fy * 87000 / (87000 + 60000)

= 0.85 * 0.85 * 3.5 / 60 * 87000 / (87000 + 60000) = 0.02494

ρmax = 0.75 * 0.02494 = 0.0187

d² = 114.44 * 12 / 0.90 * 0.0187 * 60 * 10 (1 – 0.59 * 0.0187 * 60 / 3.50)

d = 12.95, Clear cover = 2”, Total depth = 12.95+2 = 14.95. Say, d = 15 “

Provided Beam size = 15” * 10”, d = 15”- 2”= 13”

Main steel calculation:

As = Mu / φfy (d – a / 2)

= 114.44 * 12 / 0.90 * 60 (13 – 1 / 2) = 2.034 in², a = Asfy / 0.85fc bw

a = 2.034 * 60 / 0.85 * 3.5 * 10 = 4.102 in.

As = 114.44 * 12 / 0.90 * 60 (13 – 4.102 / 2) = 2.322 in²

a = 2.322 * 60 / 0.85 * 3.5 * 10 = 4.683 in

As = 114.44 * 12 / 0.90 * 60 (13 – 4.683 / 2) = 2.386 in². Use – 2 # 9 +2 # 5 bars

Main steel calculation:

Mid section:

As = Mu / φfy (d – a / 2)

= 60.52 * 12 / 0.90 * 60 (13 – 1 / 2) = 1.075 in², a = Asfy / 0.85fc bw

a = 1.075 * 60 / 0.85 * 3.5 * 10 = 2.168 in.

As = 60.52 * 12 / 0.90 * 60 (13 – 2.168 / 2) = 1.128 in²

a = 1.128 * 60 / 0.85 * 3.50 * 10 = 2.274 in

As = 60.52 * 12 / 0.90 * 60 (13 – 2.274 / 2) = 1.133 in². Use – 4 # 5 bars

Shear reinforcement design:

Vs = Vu – φVc

= 24.47 – (2 * 0.85√3500 * 10 * 13) / 1000 = 17.412 kip

4 √fc bw d = (4√3500 * 10 * 13) / 1000 = 30.763 kip

Vs < 4√fc bw d So, ok

Stirrup spacing:

1) Smax = Avfy / 50 bw = (2 * 0.11 * 60000) / 50 * 10 = 26.40”

2) Smax = d / 2 = 13 / 2 = 6½”

3) Smax = 24”

4) S = φ Avfy d / Vs = 0.85 * 2 * 0.11 * 60000 * 13 / (17.412 * 1000) = 8.37”

Use stirrups # 3 bar @ 6½” c/c

Design of the beam: B14, B17, B20, B23 ( at 1st story )

From load combination:

Maximum moment at mid section

Negative moment = 169.91 k – ft

Mu = ф ρfy bd² (1 – 0.59 ρfy / fc)

d² = Mu / (фρfy bd (1 – 0.59 ρfy / fc)

ρ max = 0.75 ρb , ρb = 0.85 β1 fc / fy * 87000 / (87000 + 60000)

= 0.85 * 0.85 * 3.5 / 60 * 87000 / (87000 + 60000) = 0.02494

ρ max = 0.75 * 0.02494 = 0.0187

d² = 169.91 * 12 / 0.90 * 0.0187 * 60 * 12 (1- 0.59 * 0.0187 * 60 / 3.50)

d =14.40, Clear cover = 2”, Total depth = 14.40+2= 16.40. Say, d = 18”

Provided Beam size = 18” * 12”, d = 18”- 2”= 16”

Main steel calculation:

As = Mu / φfy (d – a / 2)

= 169.91 * 12 / 0.90 * 60 (16 -1 /2) = 2.43 in², a = Asfy / 0.85fc bw.

a = 2.43 * 60 / 0.85 * 3.5 * 12 = 4.08

As = 169.91 * 12 / 0.90 * 60 (16 – 4.08 / 2) = 2.70 in²

a = 2.70 * 60 / 0.85 * 3.5 * 12 = 4.54 in.

As = 169.91 * 12 / 0.90 * 60 (16 – 4.54 / 2) = 2.75 in². Use – 2 # 9 +2 # 6 bars

Main steel calculation:

Mid section:

As = Mu / φfy (d – a / 2)

= 104.10 * 12 / 0.90 * 60 (16 – 1 / 2) = 1.49 in², a = Asfy / 0.85f’c bw

a = 1.49 * 60 / 0.85 * 3.5 * 10 = 3.0 in

As = 104.10 * 12 / 0.90 * 60 (16 – 3.00 / 2) = 1.59 in²

a = 1.59 * 60 / 0.85 * 3.50 *10 = 3.206 in.

As = 104.10 * 12 / 0.90 * 60 (16 – 3.206 / 2) = 1.60 in². Use – 2 # 7 +2 # 5 bars

Shear reinforcement design:

Vs = Vu – φVc

= 44.19 – (2 * 0.85√3500 * 12 * 16) / 1000 = 24.88 kip

4 √fc bw d = (4√3500 * 12 * 16) / 1000 = 45.435 kip

Vs < 4√fc bw d So, ok

Stirrup spacing:

1) Smax = Avfy / 50 bw = (2 * 0 .11 * 60000) / 50 * 10 = 26.40”

2) Smax = d / 2 = 16 / 2 = 8”

3) Smax = 24”

4) S = φ Avfyd / Vs = 0.85 * 2 * 0.11 * 60000 * 16 / (24.88 * 1000) = 7.21 ”

Use stirrups # 3 bar @ 7” c/c

Design of the beam: B13, B15, B16, B18, B19, B21, B22, B24 (at 1st story)

From load combination:

Maximum moment at end section

Negative moment = 114.84 k-ft

Mu = ф ρfy bd² (1 – 0.59 ρfy / fc)

d² = Mu / (ф ρfy bd (1 – 0.59ρfy / fc)

ρ max = 0.75 ρb, ρb = 0.85 β1 fc / fy * 87000 / (87000 + 60000)

= 0.85 * 0.85 * 3.5 / 60 * 87000 / (87000 + 60000) = 0.02494

ρ max = 0.75 * 0.02494 = 0.0187

d² = 114.84 * 12 / 0.90 * 0.0187 * 60 * 10 (1 – 0.59 * 0.0187 * 60 / 3.50)

d = 12.97, Clear cover = 2”, Total depth = 12.97+2 = 14.97. Say, d = 15”

Provided Beam size = 15” * 10”, d = 15”- 2”= 13”

Main steel calculation:

As = Mu / φfy (d – a / 2)

= 114.84 * 12 / 0.90 * 60 (13 – 1 / 2) = 2.041 in², a = Asfy / 0.85fc bw

a = 2.041 * 60 / 0.85 * 3.5 * 10 = 4.116 in.

As = 114.84 * 12 / 0.90 * 60 (13 – 4.116 / 2) = 2.332 in²

a = 2.332 * 60 / 0.85 * 3.5 * 10= 4.703 in.

As = 114.84 * 12 / 0.90 * 60 (13 – 4.703 / 2) = 2.396 in². Use – 2 # 8 +2 # 6 bars

Main steel calculation:

Mid section:

As = Mu / φfy (d – a / 2)

= 51.04 * 12 / 0.90 * 60 (13 – 1 / 2) = 0 .907 in², a = Asfy / 0.85fc bw

a = 0.907 * 60 / 0.85 * 3.5 * 10 = 1.829 in.

As = 51.04 * 12 / 0.90 * 60 (13 – 1.829 / 2) = 0.938 in²

a = 0.938 * 60 / 0.85 * 3.50 * 10 = 1.891 in.

As = 51.04 * 12 / 0.90 * 60 (13 – 1.891 / 2) = 0.941 in². Use – 3 # 5 bars

Shear reinforcement design:

Vs = Vu – φVc

= 32.71 – (2 * 0.85√3500 * 10 * 13) / 1000 = 18.92 kip

4 √fc bwd = (4√3500 *10 * 13) / 1000 = 30.763kip

Vs < 4√fc bw d So, ok

Stirrup spacing:

1) Smax = Avfy / 50 bw = (2 * 0.11 * 60000) / 50 * 10 = 26.40”

2) Smax = d / 2 = 13 / 2 = 6½”

3) Smax = 24”

4) S = φ Avfy d/ Vs = 0.85 * 2 * 0.11 * 60000 * 13 / (18.92 * 1000) = 7.71 ”

Use stirrups # 3 bar @ 6½” c/c

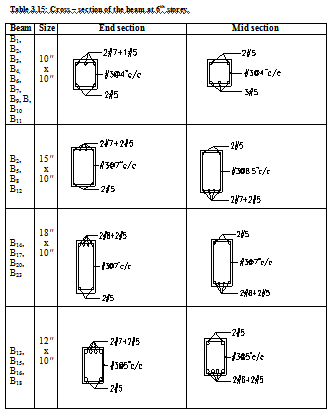

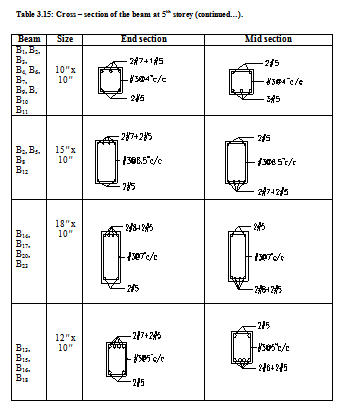

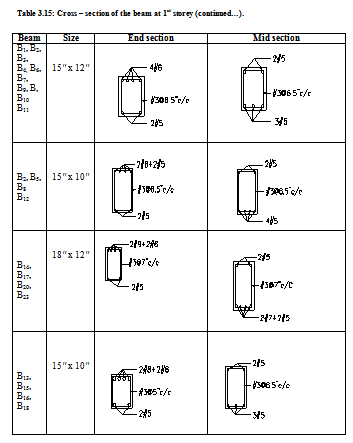

The table below is showing cross section of different floor beams at their end sections and mid section.

Column design for beam supported structure.

Column design for beam supported structure.

Design of the Column: C1, C4, C10, C16

From load combination:

Pu = 329.81 Kips = 329.81*1.20 = 396 Kips

Now, Pu = α ф Ag (0 .85 f’c (1- ρg) + ρg fy)

Or 396 = 0.80 * 0.65 * Ag (0.85 * 3.5 (1- 0.025) + 0.025 * 60)

Or 396 = 2.288 Ag Or Ag = 173.076 in2 Or Ag = 10” * 18”

Provided Column size = 10” * 18”, Ag = 180 in2

Main steel calculation:

Pu = α ф (0 .85 f’c (Ag – A) + Asfy)

Or 396 = 0.80 * 0.65 (0.85 * 3.5 (180 – As) + As * 60)

Or 396 = 278.46 – 1.547As + 31.20 As. Or As = 3.963 in2

Use 4 # 8 bars +2 # 6 bars, As = 4.04 in2

Tie design:

Spacing: S = 16 D = 16 * 6 / 8 = 12” c/c, S = 48 d = 48 * 3 / 8 = 18” c/c

At least lateral dimension, S = 10” c/c. Use # 3 bar ties @ 10” c/c.

Y – Axis:

γ = 13 / 18 = 0.72, ex = Mx / P = 56.093 * 12 / 329.81= 2.04 in

ey = My / P = 1.78 * 12/329.81 = 0.06 in, ex / h = 2.04 / 18 = 0.113

Reinforcement Ratio: ρg =As / A g = 4.04 / 180 = 0.022

From Graph: Pn yo / f′c Ag = 0.91

Or Pn yo = 0.91 * 3.50 * 180 = 573.30 kips

Po / f′c Ag = 1.11 Or Po = 1.11 * 3.50 * 180 = 699.30 kips

X – Axis:

γ = 5 / 10 = 0.5, ex = Mx / P = 56.093 * 12/329.81= 2.04 in

ey = My / P = 1.78*12 / 329.81 = 0.06 in, ey / h = 0.06 / 10 = 0.006

Reinforcement ratio: ρg =As / A g = 4.04 / 180 = 0.022

From Graph: Pn xo / f′c Ag = 1.02

Or Pn xo = 1.02 * 3.50 * 180 = 642.60 kips

Po /f′c Ag = 1.11 Or Po = 1.11 * 3.50 * 180 = 699.30 kips

Here – 1 / Pn = 1 / Pnxo + 1 / Pnyo – 1 / Po

Or 1 / Pn = 1 / 642.60 + 1 / 573.30 – 1 / 699.30. Or Pn = 534.64 kips

Now, Pu = ф Pn. Or Pu = 0.65 * 534.64

Or Pu = 347.516 kips > 329.81 kips. So design is ok.

Design of the Column : C2, C3, C5, C8, C9, C12, C14, C15

From load combination:

Pu = 532.65 Kips = 532.65 * 1.20 = 639.18 Kips

Now, Pu = α ф Ag (0 .85 f’c (1- ρg) + ρg fy)

Or 639.18 = 0.80 * 0.65 * Ag (0.85 * 3.5 (1- 0.025) + 0.025 * 60)

Or 639.18 = 2.288 Ag or Ag = 279.36 in2 or Ag= 12” *24”

Provided Column size = 12” * 24”, Ag = 288 in2

Main steel calculation:

Pu = α ф (0 .85 f′c (Ag – As) + Asfy)

Or 639.18 = 0.80 * 0.65 (0.85 * 3.5 (288 – As) + As * 60)

Or 639.18 = 445.54 – 1.547 As + 31.20 As

Or As = 6.53 in2 Use 4 # 8 bars + 8 # 6 bars As = 6.68 in2

Tie design:

Spacing: S = 16 D = 16 * 6 / 8 = 12” c/c, S = 48 d = 48 * 3 / 8 = 18” c/c

At least lateral dimension: S = 12” c/c, Use # 3 bar ties @ 12” c/c.

Y – Axis:

γ = 19 / 24 = 0.79, ex = Mx / P = 54.898 * 12 / 532.65 = 1.24 in

ey = My / P = 1.534 * 12 / 532.65 = 0.035 in, ex / h = 1.24 / 24 = 0.052

Reinforcement ratio: ρg = As / A g = 6.68 / 288 = 0.023

From Graph: Pn yo / f′c Ag = 0.98

Or Pn yo = 0.98 * 3.50 * 288 = 987.84 kips

Po / f′c Ag = 1.13 Or Po = 1.13 * 3.50 * 288 = 1139.04 kips

X – Axis: γ = 7 / 12 = 0.58, ex = Mx / P = 54.898 * 12 / 532.65 = 1.24 in

ey = My / P = 1.534 * 12 / 532.65 = 0.035 in, ey / h = 0.035 / 12 = 0.0029

Reinforcement Ratio: ρg = As / A g = 6.68 / 288 = 0.023

From Graph: Pn xo / f′c Ag = 1.13

Or Pn xo = 1.13 * 3.50 * 288 = 1139.04 kips

Po / f′c Ag = 1.0 Or Po = 1.05 * 3.50 * 288 = 1058.40 kips

Here – 1 / Pn = 1 / Pnxo + 1 / Pnyo – 1 / Po

Or 1 / Pn = 1 / 1058.40 + 1 / 987.84 – 1 / 1139.04 or Pn = 926.61 kips

Now, Pu = ф Pn or Pu = 0.65 * 926.61

Or Pu = 602.30 kips > 532.65 kips, so design is ok.

Design of the Column : C6, C7, C11, C13

From load combination:

Pu = 865.56 Kips = 865.56 * 1.20 = 1038.67 Kips

Now, Pu = α ф Ag (0 .85 f’c (1- ρg) + ρg fy)

Or 1038.67 = 0.80*0.65 * Ag (0.85 * 3.5 (1- 0.025) + 0.025 * 60)

Or 1038.67 = 2.288 Ag or Ag = 454 in2 or Ag = 18” * 26”

Provided Column size = 18” * 26”, Ag = 468 in2

Main steel calculation:

Pu = α ф (0 .85 f’c (Ag – As) + Asfy)

Or 1038.67 = 0.80 * 0.65 (0.85 * 3.5 (468 – As) + As * 60)

Or 1038.67 = 723.99– 1.547As + 31.20 As

Or As = 10.61 in2 use 4 # 10 bars + 6 # 9 bars As = 11.08 in2

Tie design:

Spacing: S = 16 D = 16 * 9/8 = 18” c/c, S = 48 d = 48 * 3/8 = 18” c/c

At least lateral dimension: S = 18” c/c, use # 3 bar ties @ 18” c/c.

Y – Axis:

γ = 21 / 26 = 0.80, ex = Mx / P = 0.971 * 12 / 865.56 = 0.013 in

ey = My / P = 61.64 * 12 / 865.56 = 0.85 in, ex / h = 0.013 / 26 = 0.0005

Reinforcement ratio: ρg = A s / A g = 11.08 / 468 = 0.024

From Graph: Pn yo / f′c Ag = 1.15

Or Pn yo = 1.15 * 3.50 * 468 = 1883.70 kips

Po / f′c Ag = 1.15 or Po = 1.15 * 3.50 * 468 = 1883.70 kips

X – Axis:

γ = 13 / 18 = 0.72, ex = Mx / P = 0.013 in, ey = My / P = 0.85 in

ey / h = 0.85 / 18 = 0.047

Reinforcement ratio: ρg = As / A g = 0.024

From Graph: Pn xo / f′c Ag = 1.00

Or Pn xo = 1.00 * 3.50 * 468 = 1638 kips

Po / f′cAg = 1.15 or Po = 1.15 * 3.50 * 468 = 1883.70 kips

Here – 1 / Pn = 1 / Pnxo + 1 / Pnyo – 1 / Po

Or 1/Pn = 1 / 1638 + 1 / 1883.70 – 1 / 1883.7 or Pn = 1638 kips

Now, Pu = ф Pn, or Pu = 0.65 * 163

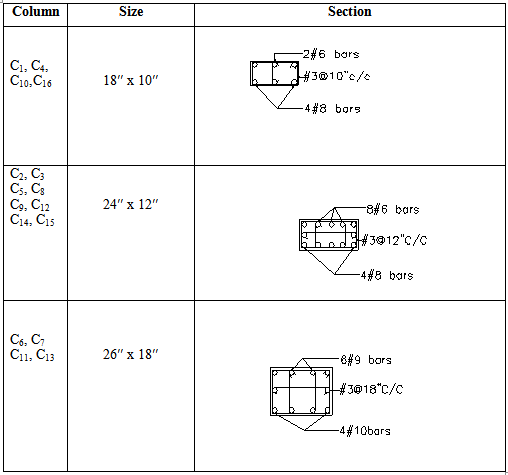

The table below is showing size of different columns of the beam supported structure.

Table 3.16: Cross -section of the Column of the beam supported structure

Column design for flat plate structure

Design of the Column : C1, C4, C10, C16

From load combination:

Pu = 232.26 Kips = 232.26 * 2.0 = 464.52 Kips

Now, Pu = α ф Ag (0 .85 f’c (1- ρg) + ρg fy)

Or 464.52 = 0.80 * 0.65 * Ag (0.85 * 3.50 (1- 0.03) + 0.03 * 60)

Or 464.52 = 2.44 Ag Or Ag = 190.40 in2. Or Ag = 13.79” *13.79”

Provided Column size = 15” *15”, Ag = 225 in

Main steel calculation:

Pu = α ф (0 .85 fc (Ag – As) + Asfy)

Or 464.52 = 0.80 * 0.65 (0.85 * 3.50 (225 – As) + As * 60)

Or 464.52 = 348.70 – 1.547As + 31.20 As. Or As = 3.92 in2

Use 4 # 9 bars, As = 4.00 in2

Tie design:

Spacing: S = 16 D = 16 * 9/8 = 18” c/c, S = 48 d = 48 * 3 / 8 = 18” c/c

At least lateral dimension: S = 15” c/c, use # 3 bar ties @ 15” c/c.

Y – Axis:

γ = 10 / 15 = 0.67, ex = Mx / P = 94.34 * 12/232.26 = 4.87 in

ey = My / P = 3.293 * 12/232.26 = 0.17 in, ex / h = 4.87 / 15 = 0.32

Reinforcement ratio:

ρg = As / A g = 4.00 / 225 = 0.018

From Graph,

Pn yo / f′c Ag = 0.53

Or Pn yo = 0.53 * 3.50 * 225 = 417.37 kips, Po/ f′c Ag = 1.09

Or Po = 1.09 * 3.50 * 225 = 858.37 kips

X – Axis:

γ = 10 / 15 = 0.67, ex = Mx / P = 4.87 in, ey = My / P = 0.17 in

ey / h = 0.17 / 15 = 0.011

Reinforcement Ratio: ρg = As / A g = 0.018

From Graph:

Pn xo / f′c Ag = 1.06 Or Pn xo = 1.06 * 3.50 * 225 = 834.75 kips

Po / f′c Ag =1.09 Or Po = 1.09 * 3.50 * 225 = 858.37 kips

Here – 1/ Pn = 1 / Pnxo + 1 / Pnyo – 1 / Po

Or 1/Pn = 1 / 834.75+ 1 / 417.37– 1 / 858.37 Or Pn = 411.70 kips

Now, Pu = ф Pn. Or Pu = 0.65 * 411.70

Or Pu = 267.60 kips > 232.26 kips. So design is ok.

Design of the Column : C2, C3, C5, C8, C9, C12, C14, C15

From load combination:

Pu = 469.38 Kips = 469.38 * 1.20 = 563.25 Kips

Now, Pu = α ф Ag (0 .85 f’c (1- ρg) + ρg fy)

Or 563.25 = 0.80 * 0.65 * Ag (0.85 * 3.50 (1- 0.025) + 0.025 * 60)

Or 563.25 = 2.288 Ag Or Ag = 246.18 in2

Or Ag =12” *24”

Provided Column size =12” *24”

Ag = 288 in2

Main steel calculation:

Pu = α ф(0 .85 f’c (Ag – As) + Asfy)

Or 563.25 = 0.80 * 0.65 (0.85 * 3.50 (288 – As) + As * 60)

Or 563.25 = 445.54 – 1.547As + 31.20 As Or As = 3.97 in2

Use 4 # 8 bars + 2 # 6 bars, As = 4.04 in2

Tie design:

Spacing: S = 16 D = 16 * 6 / 8 = 12” c/c, S = 48 d = 48 * 3 / 8 = 18” c/c

At least lateral dimension, S = 12” c/c

Use # 3 bar ties @ 12” c/c.

Y – Axis:

γ = 19 / 24 = 0.79, ex = Mx / P = 94.668 * 12 / 469.38 = 2.42 in

ey = My / P = 2.533 * 12 / 469.38 = 0.065 in, ex / h = 2.42 / 24 = 0.10

Reinforcement ratio:

ρg = As / A g = 4.04 / 288 = 0.014

From Graph: Pn yo / f′c Ag = 0.86

Or Pn yo = 0.86 * 3.50 * 288 = 866.88 kips

Po / f′c Ag = 1.04 Or Po = 1.04 * 3.50 * 288 = 1048.32 kips

X – Axis:

γ = 7 / 12 = 0.58, ex = Mx / P = 2.42 in, ey = My / P = 0.065 in

ey / h = 0.85 / 18 = 0.047

Reinforcement ratio: ρg =As / A g = 0.014

From Graph: Pn xo / f′c Ag = 1.04

Or Pn xo = 1.04 * 3.50 * 288 = 1048.32 kips

Po / f′c Ag = 1.04 Or Po = 1.04 * 3.50 * 288 = 1048.32 kips

Here – 1 / Pn = 1 / Pnxo + 1 / Pnyo – 1 / Po

Or 1 / Pn = 1 / 1048.32+ 1 / 866.88– 1 / 1048.32

Or Pn = 869.56 kips

Now, Pu = ф Pn. Or Pu = 0.65 * 869.56

Or Pu = 565.21 kips > 469.38 kips. So design is ok.

Design of the Column : C6, C7, C11, C13

From load combination:

Pu = 1075.60 Kips = 1075.60 * 1.40 = 1505.84 Kips

Now, Pu = α ф Ag (0 .85 f’c (1- ρg) + ρg fy)

Or 1505.84 = 0.80 * 0.65 * Ag (0.85 * 3.50 (1- 0.03) + 0.03 * 60)

Or 1505.84 = 2.44 Ag Or Ag = 617.15 in Or Ag = 22” * 30”

Provided Column size = 22” * 30”

Ag = 660 in2

Main steel calculation:

Pu = α ф (0 .85 f’c (Ag – As) + Asfy)

Or 1505.84 = 0.80 * 0.65 (0.85 * 3.50 (660 – As) + As * 60)

Or 1505.84 =1021.02 – 1.547As + 31.20 As

Or As = 16.35 in2

Use 4 # 10 bars + 12 # 9 bars, As = 17.08 in2

Tie design:

Spacing: S = 16 D = 16 * 9 / 8 = 18” c/c, S = 48 d = 48 * 3 / 8 = 18” c/c

At least lateral dimension, S = 22” c/c, Use # 3 bar ties @ 18” c/c.

Y – Axis:

γ = 25 / 30 = 0.83, ex = Mx / P = 4.06 * 12 / 1075.60 = 0.045 in

ey = My / P = 135.407 * 12 / 1075.60 = 1.51 in

ex / h = 0.045 / 30 = 0.0015

Reinforcement ratio: ρg = As / A g = 17.08 / 660 = 0.026

From Graph: Pn yo / f′c Ag = 1.108

Or Pn yo = 1.108 * 3.50 * 660 = 2559.48 kips

Po / f′c Ag = 1.20 Or Po = 1.20 * 3.50 * 660 = 2772 kips

X – Axis:

γ = 17 / 22 = 0.77, ex = Mx / P = 0.045 in, ey = My / P = 1.51 in

ey / h = 1.51 / 22 = 0.0686

Reinforcement ratio: ρg = As / A g = 0.026

From Graph: Pn xo / f′c Ag = 1.09

Or Pn xo = 1.09 * 3.50 * 660 = 2517.90 kips

Po/ f′c Ag = 1.20

Or Po = 1.20 * 3.50 * 660 = 2772 kips

Here – 1 / Pn = 1 / Pnxo + 1 / Pnyo – 1 / Po

Or 1 / Pn = 1 / 2517.90 + 1 / 2559.48 – 1 / 2772

Or Pn = 2341.31kips

Now, Pu = ф Pn. Or Pu = 0.65 * 2341.31

Or Pu = 1521.85 kips > 1075.60 kips. So design is ok.

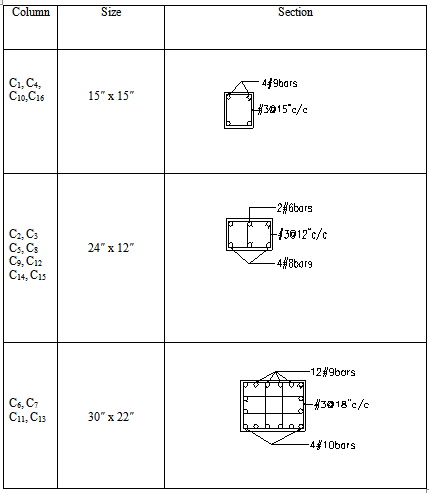

The table below is showing size of different columns of the flat plate structure

Table 3.17: Cross section of the column elements for flat plate structure.

Some are parts:

Analysis Between a Beam Supported Structure and a Flat Plate Structure (Part 1)

Analysis Between a Beam Supported Structure and a Flat Plate Structure (Part 2)

Analysis Between a Beam Supported Structure and a Flat Plate Structure (Part 3)