With the introduction of wearable devices that can detect a pulse, brain activity, biomarkers in sweat, and more, medical sensing technology has advanced significantly in recent years. Existing wearable pressure sensors, however, have one major flaw: even the tiniest amount of pressure, such as a tight long sleeve shirt over a sensor, might throw it off track.

Texas engineers have found a solution to a problem that has plagued the field for years. They did so by developing the world’s first hybrid sensing technique, which allows the device to have properties from both the most common types of sensors in use today.

“The field of flexible pressure sensors is extremely crowded, and after two decades we hit a bottleneck because no one could solve the tradeoff between pressure and sensitivity,” said Nanshu Lu, an associate professor in the Department of Aerospace Engineering and Engineering Mechanics and the corresponding author of the new research published today in Advanced Materials. “This is the first sensor able to leverage a new hybrid mode to withstand pressure without a significant decay in sensitivity.”

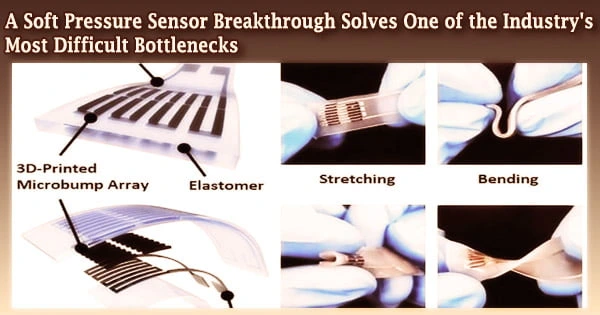

Today’s soft pressure sensors typically consist of three layers: a deformable sensing layer sandwiched between two electrodes. The two types of piezoelectric sensors are piezo-capacitive and piezo-resistive.

Lu’s team used an electrically conductive and extremely porous nanocomposite as the sensing layer, as well as an additional insulating layer, to provide the sensor the ability to function as both types of sensors. Its ability to tolerate pressure is due to the innovative hybrid sensing.

When sensors are subjected to pressures greater than a light touch, their sensitivity drops by a factor of ten. When this sensor was placed on a test subject’s forehead, it was able to endure the pressure of a tight-fitting virtual reality headgear on top of it with relatively minor sensitivity loss.

The field of flexible pressure sensors is extremely crowded, and after two decades we hit a bottleneck because no one could solve the tradeoff between pressure and sensitivity. This is the first sensor able to leverage a new hybrid mode to withstand pressure without a significant decay in sensitivity.

Nanshu Lu

Pressure can affect the accuracy of many sensors, as well as their ability to transmit a reading at all.

“As we apply external pressure, the sensitivity drops, but is still on par with other sensors at zero pressure,” said Lu, who also has appointments in the Department of Electrical and Computer Engineering, Walker Department of Mechanical Engineering, Department of Biomedical Engineering and UT Austin’s Texas Materials Institute.

Lu has long been a pioneer in this sector, particularly through her electronic tattoo technology, a series of devices that are so light and stretchy that they may be worn for lengthy periods of time over the heart, brain, or muscle with little or no discomfort.

However, Lu has bigger plans for these sensors and e-tattoos. She’s trying to figure out how to wrap the sensor material around practically any item and give it the sensitivity of human skin.

Wrapping it over robotic hands and fingers gives them the ability to detect items by touching them is the most obvious application. However, it is capable of a wide range of functions.

“The applications could be unlimited,” Lu said. “Stretchable, e-skin could be wrapped around almost any object.”