Terahertz radiation, whose wavelengths are between microwaves and visible light, can penetrate many nonmetallic materials and detect molecular signatures. These useful properties could be applied to a wide range of applications, including airport security scanning, industrial quality control, astrophysical observations, nondestructive material characterization, and wireless communications with higher bandwidth than current cellphone bands.

However, designing devices to detect and generate images from terahertz waves has proven difficult, with most existing terahertz devices being expensive, slow, and bulky, requiring vacuum systems and extremely low temperatures.

Researchers from MIT, the University of Minnesota, and Samsung have created a new type of camera that can detect terahertz pulses quickly, with high sensitivity, and at room temperature and pressure. Furthermore, unlike existing devices, it can simultaneously capture information about the orientation, or “polarization,” of the waves in real time. This data can be used to characterize asymmetrical molecules in materials or to determine the surface topography of materials.

The photons of terahertz radiation have extremely low energy, which makes them hard to detect. So, what this device is doing is converting that little tiny photon energy into something visible that’s easy to detect with a regular camera.

Keith Nelson

The new system employs quantum dots, which have recently been discovered to emit visible light when stimulated by terahertz waves. The visible light is then recorded by a device similar to the detector of a standard electronic camera and can even be seen with the naked eye. The device is described in a paper published in the journal Nature Nanotechnology on November 4 by MIT doctoral student Jiaojian Shi, chemistry professor Keith Nelson, and 12 others.

The team created two different room-temperature devices: one that uses the quantum dot’s ability to convert terahertz pulses to visible light, allowing the device to produce images of materials, and the other that produces images of the polarization state of the terahertz waves.

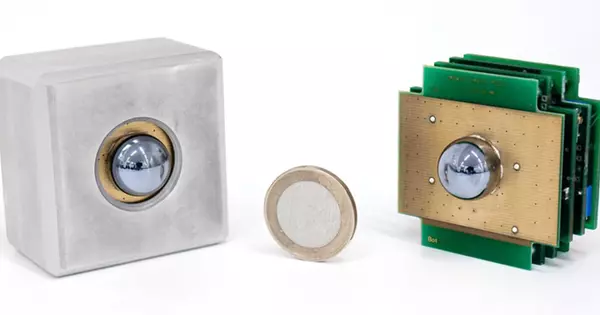

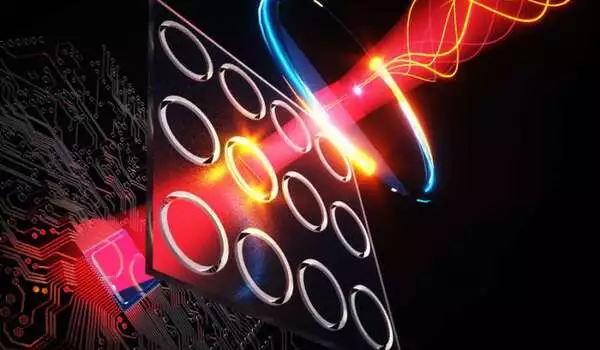

The new “camera” consists of several layers, made with standard manufacturing techniques like those used for microchips. An array of nanoscale parallel lines of gold, separated by narrow slits, lies on the substrate; above that is a layer of the light-emitting quantum dot material; and above that is a CMOS chip used to form an image. The polarization detector, called a polarimeter, uses a similar structure, but with nanoscale ring-shaped slits, which allows it to detect the polarization of the incoming beams.

The photons of terahertz radiation have extremely low energy, Nelson explains, which makes them hard to detect. “So, what this device is doing is converting that little tiny photon energy into something visible that’s easy to detect with a regular camera,” he says. In the team’s experiments, the device was able to detect terahertz pulses at low-intensity levels that surpassed the capability of today’s large and expensive systems.

The researchers demonstrated the capabilities of the detector by taking terahertz-illuminated pictures of some of the structures used in their devices, such as the nano-spaced gold lines and the ring-shaped slits used for the polarized detector, proving the sensitivity and resolution of the system.

A practical terahertz camera requires two components: one that generates terahertz waves to illuminate a subject and another that detects them. On the latter point, current terahertz detectors are either very slow because they rely on detecting heat generated by waves striking a material, and heat propagates slowly, or they use photodetectors, which are relatively fast but have very low sensitivity. Furthermore, until now, most approaches required an entire array of terahertz detectors, each producing one pixel of the image. “Each one is quite expensive,” Shi says, so “once they start making a camera, the cost of the detectors starts to scale up really, really quickly.”

While the researchers say they have cracked the terahertz pulse detection problem with their new work, the lack of good sources remains—and is being worked on by many research groups around the world. The terahertz source used in the new study is a large and cumbersome array of lasers and optical devices that cannot easily be scaled to practical applications, Nelson says, but new sources-based microelectronic techniques are well under development.

“I think that’s really the rate-limiting step: Can you make the [terahertz] signals in a facile way that isn’t expensive?” he says. “But there’s no question that’s coming.”

Sang-Hyun Oh, a co-author of the paper and a McKnight Professor of Electrical and Computer Engineering at the University of Minnesota, adds that while present versions of terahertz cameras cost tens of thousands of dollars, the inexpensive nature of CMOS cameras used for this system makes it “a big step forward toward building a practical terahertz camera.” The potential for commercialization led Samsung, which makes CMOS camera chips and quantum dot devices, to collaborate on this research.

According to Nelson, traditional detectors for such wavelengths operate at liquid helium temperatures (-452 degrees Fahrenheit), which is required to separate the extremely low energy of terahertz photons from background noise. The fact that this new device can detect and produce images of these wavelengths at room temperature using a conventional visible-light camera has surprised those working in the terahertz field. “‘What?’ say the onlookers. It’s almost unheard of, and people are taken aback “Oh says

According to the researchers, there are numerous ways to improve the sensitivity of the new camera, including further miniaturization of the components and methods of protecting the quantum dots. Even at the current detection levels, they believe the device has some potential applications.

Nelson claims that quantum dots, which are currently used in consumer products such as television screens, have a high commercialization potential for the new device. He claims that the actual fabrication of the camera devices is more complicated, but that it is also based on existing microelectronics technology. In fact, unlike current terahertz detectors, the entire terahertz camera chip can be manufactured using today’s standard microchip production systems, implying that mass production of the devices should be possible and relatively inexpensive in the future.