While both recycling and upcycling reduce the amount of garbage that ends up in landfills, upcycling transforms the same waste into a higher-quality product, whereas recycling slightly reduces the quality of certain materials. It is the creative reuse of plastic waste materials to create new materials with higher quality and environmental value. Plastics in various forms are non-biodegradable and can last for a very long time in the environment.

Researchers have developed a clean and cost-effective method for repurposing used plastic, converting it into valuable nanomaterials and high-quality fuel.

Important points –

- Cutting-edge technology creates carbon nanotubes and clean liquid fuel from waste plastic.

- Ingenious solution for upcycling plastic and agricultural waste at the same time.

- A circular economy approach will assist in converting two massive waste streams into genuine revenue.

Only about 20% of waste plastics are recycled globally. Increasing that figure remains a challenge because recycling plastic cleanly can be costly and often results in lower-value products, making it financially unviable.

Researchers at RMIT University in Melbourne, Australia, have developed a new method for producing high-value products from plastic, such as carbon nanotubes and clean liquid fuel, while also upcycling agricultural and organic waste.

Researchers have developed a clean and cost-effective way to upcycle used plastic, transforming it into valuable nanomaterials and high-quality fuel.

Kalpit Shah

The team’s two-step process, described in the Journal of Environmental Management, converts organic waste into a carbon-rich, high-value form of charcoal, which is then used as a catalyst to upcycle plastic.

According to Associate Professor Kalpit Shah, the lead researcher, upcycling two massive waste streams through a single circular economy approach could result in significant financial and environmental benefits. “Our method is clean, cost-effective, and easily scalable,” Shah explained.

“It’s an ingenious way to recycle both used plastic and organic waste, whether it’s tons of biomass from a farm or food waste and garden clippings from household green bins. We hope that in the future, local governments and councils will be able to use this technology to help turn waste into genuine revenue streams.”

High-value nanomaterials

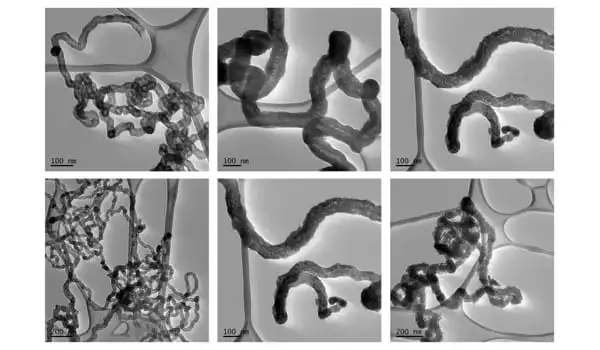

The new plastic upcycling method provides a sustainable alternative for producing carbon nanotubes (CNTs). These hollow, cylindrical structures have exceptional electronic and mechanical properties, making them useful in a variety of industries such as hydrogen storage, composite materials, electronics, fuel cells, and biomedical technologies.

Carbon nanotubes are becoming increasingly popular, particularly in aerospace and defense, where they can help with the design of lightweight parts. The global market for carbon nanotubes is expected to reach $5.8 billion by 2027.

Turning old into new

The new method begins by converting agricultural or organic waste into biochar, a carbon-rich form of charcoal that is commonly used to improve soil health. As waste plastic is broken down into its constituents of gas and oil, the biochar is used to eliminate toxic contaminants such as polycyclic aromatic hydrocarbons (PAHs).

The process removes contaminants while also converting plastics into high-quality liquid fuel. Simultaneously, the carbon in the plastic is converted into carbon nanotubes that coat the biochar. These nanotubes can be exfoliated and used in a variety of industries, or nano-enhanced biochar can be used directly for environmental remediation and agricultural soil enhancement.

The research is the first to use low-cost, widely available biochar as a catalyst in the production of contaminant-free fuel and carbon nanomaterials from plastic. While the study only investigated one type of plastic, Shah, the Deputy Director (Academic) of the ARC Training Centre for Transformation of Australia’s Biosolids Resource at RMIT, stated that the approach would be applicable to a variety of plastic types.

“We concentrated on polypropylene because it is widely used in the packaging industry,” he explained. “While more research is needed to test different plastics because the quality of the fuel produced will vary, the method we’ve developed is generally suitable for upcycling any polymers – the base ingredients for all plastic.”

Hyper-efficient reactor

The lab-scale experimentation can also be replicated in a new type of hyper-efficient reactor developed and patented by RMIT. The reactor uses fluidized bed technology and provides significant improvements in heat and mass transfer, lowering overall capital and operating costs.

The upcycling research will continue with detailed computer modeling to optimize the methodology, followed by pilot trials in the reactor. The RMIT School of Engineering team is eager to collaborate with the plastic and waste industries in order to advance the research and investigate other potential applications of the upcycling method.