In a recent work, experts in the field of materials were inspired by birds’ structural colors to create non-iridescent nanoparticle assemblies. For the purpose of identifying structure-color correlations and producing designer materials with customized color, nanoparticle mixes with different particle chemistries and sizes can alter the color that is created.

In a new report on Science Advances, Christian M. Heil, and a research team at several international, multidisciplinary research institutes in the U.S., Belgium, and Germany, showed how to reconstruct the assembled structures via small-angle scattering measurements.

The study team was able to demonstrate the impact of a single layer of separated nanoparticles and develop an interesting color by accurately and quantitatively predicting the experimentally observed colors in mixtures containing significantly absorbed nanoparticles. The adaptable computational techniques used in this work helped to create synthetic materials with the appropriate colors suitable for usage as food coloring, cosmetics, and paintings.

Synthetic color fabrication and characterization.

The various hues of color seen in nature serve as inspiration for the color synthesis of synthetic materials. They might result from the spatial arrangement of color-resistant nanostructured materials. Iridescent hues can occur in materials with regular, periodic nanostructures, but not in those with short-range organization.

By using amorphous assemblies of inorganic nanoparticles to self-assemble polymeric nanoparticles, materials scientists can replicate natural non-iridescent structural hues. In order to promote structural variety, they can control the structure and optical characteristics of nanoparticle assemblies to change the colors of the assemblies.

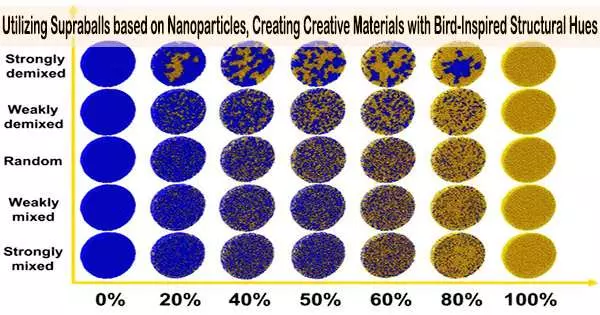

By creating a wide range of unique structures and structural colors, scientists are able to modify the nanoparticle size ratio between the constituents and the composition.

Characterizing designer materials

Heil et al. used small-angle scattering and electron microscopy to obtain structural information of the designer materials. They also combined small-angle neutron and X-ray scattering to offer approaches that are suitable for looking at both bulk and nanoscale structural data. For optical modeling of complex nano-assemblies, they used the finite-difference time-domain (FDTD) method.

They used computational reverse-engineering analysis for scattering experiments (CREASE) to analyze the scattering experiment profile from the small-angle-scattering studies in order to produce nanoparticle assemblies.

In order to comprehend binary nanoparticle assemblies that form supraballs and produce a wide spectrum of colors, the researchers combined CREASE-FDTD approaches. The results described the optical characteristics of nanoparticle assemblies and demonstrated the ability to create custom colors for a variety of uses in paints, cosmetics, and food coloring.

Structural color diversity with binary nanoparticle mixtures

The materials scientists investigated the chemical composition and phase morphology of binary mixtures of absorbing and non-absorbing species of comparable size to offer a technique to control the structural color prediction, which was the basis for the structural color’s relative sensitivity.

This work generated a wide range of hues to demonstrate the importance of understanding the relative content of two nanoparticle types in a binary mixture together with their degree of phase segregation and mixing.

To monitor this process, Heil et al. used an experimental and computational approach, which provided information about the internal morphologies of supraballs to predict each reflectance spectra and their resulting color.

CREASE and small-angle neutron scattering data

The group created suspensions of micron-scale supraballs and carried out small-angle neutron scattering studies on three different nanoparticle combinations. By separating the contributions of distinct components to the total scattering from the target nanoparticles, they were able to gather morphological data on the interior of supraballs.

The researchers evaluated scattering results from multicomponent structures using computational reverse-engineering analysis to create 3D structural reconstructions and optical simulations of the final products.

The coordinates of every nanoparticle inside supraballs were provided by the results of the structural analysis based on computational reverse-engineering analysis for scattering experiments (CREASE). This information was useful to calculate the scattering of light by employing the finite-difference-time domain method (FDTD).

The combined CREASE-FDTD method represented a close structural match to experimental systems with optical modeling comparisons. In order to comprehend the effects of size dispersity and surface segregation on structural color, the team modelled the optical properties underlying a complicated binary combination of nanoparticles based on the remarkable agreement between these two combined methodologies.

Outlook

In this way, Christian M. Heil and colleagues combined two key methods; computational reverse-engineering analysis for scattering experiment (CREASE) and the finite-difference-time domain method (FDTD) to provide a new platform to model structural colors of nanoparticle-based supra-assemblies. While those with short-range ordering produce non-iridescent colors, the structural colors that were inspired by birds formed non-iridescent nanoparticle assemblies.

To determine the results as a function of size, dispersity, phase morphology, and strongly absorbing optical characteristics of the nanoparticles, the team used two main methodologies. With the help of these techniques, it was possible to rebuild the 3D structures of nanoparticle assemblies and create scattering profiles that closely matched those discovered by small-angle neutron scattering measurements.

In order to analyze the optical properties of considerably bigger supraball assemblies, such as packed films and pigment dispersions, multiscale modeling is a useful use of the combined method.

In order to aid materials researchers in better understanding and designing complex materials for applications across the electromagnetic spectrum, this method can create programmable colors for real-world applications in coatings, paints, and cosmetics. It also predicts material properties like thermal conductivity, electrical conductivity, and mechanical properties, which depend on the structural composition of the designed materials.