Nanofiber membranes have been shown to be effective in treating polluted water. These membranes have a high surface area-to-volume ratio, which makes them excellent at trapping and removing contaminants from water. Additionally, they have a small pore size, which allows for the removal of very small particles and microorganisms.

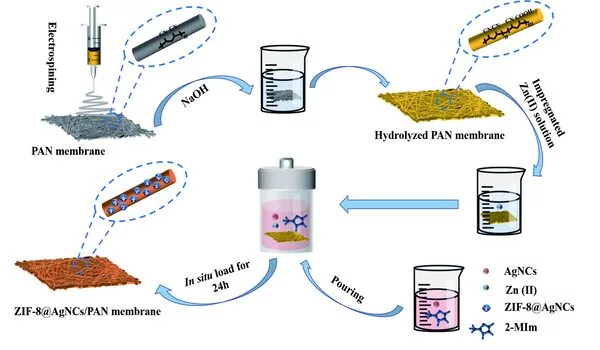

Researchers devise a method of fabrication to improve the efficacy and longevity of membrane separation technology. The researchers used electrospinning to create a nanofibrous membrane, in which a liquid polymer droplet is electrified and stretched to form fibers, and increased the roughness of the membrane surface by loading it with silver nanoparticles. This rough surface promotes the formation of a stable layer of water in water, which acts as a barrier to prevent oil droplets from entering the membrane. The technology separates a petroleum ether-in-water emulsion with greater than 99% efficiency.

When oil contaminates water, it forms a film that reduces oxygen levels while also introducing toxic substances. This can kill aquatic plants and animals, contaminate soil, and ultimately endanger human health.

We discovered that the surface roughness and hydration layer strength of the membrane are critical factors influencing its separation performance and anti-fouling ability. This concept of depositing particles on nanofibrous membranes has broad application potential with other materials.

Jindan Wu

Separating oil from polluted water is therefore critical. Current methods can be costly and difficult, and some may introduce additional pollutants into the system. Membrane materials, for example, can act as a barrier to intercept oil, but their efficiency is low and they are not suitable for long-term use.

Researchers in China developed a fabrication method to increase the efficacy and longevity of membrane separation technology in Biointerphases, an AVS journal published by AIP Publishing. The technology separates a petroleum ether-in-water emulsion with greater than 99% efficiency.

The researchers used electrospinning to create a nanofibrous membrane, in which a liquid polymer droplet is electrified and stretched to form fibers. They roughened the membrane surface by loading it with silver nanoparticles.

This rough surface promotes the formation of a stable layer of water in water, which acts as a barrier to prevent oil droplets from entering the membrane.

“This hydration layer efficiently impedes the passage of oil droplets, reducing membrane pollution and enhancing the composite membrane’s permeability and separation efficiency,” said author Jindan Wu.

Silver nanoparticles also improve the antibacterial properties of the membrane. By incorporating them, the risk of membrane corrosion caused by microorganisms is reduced.

“We discovered that the surface roughness and hydration layer strength of the membrane are critical factors influencing its separation performance and anti-fouling ability,” Wu said. “This concept of depositing particles on nanofibrous membranes has broad application potential with other materials.”

This fabrication method’s current output capabilities are limited. However, the group hopes that developing such materials will contribute to a more comprehensive solution for water pollution treatment.

“Water pollution is caused by a variety of factors, and oily wastewater is just one of them,” Wu explained. “It is critical to develop materials that can treat dyes, heavy metals, and bacteria found in water.”