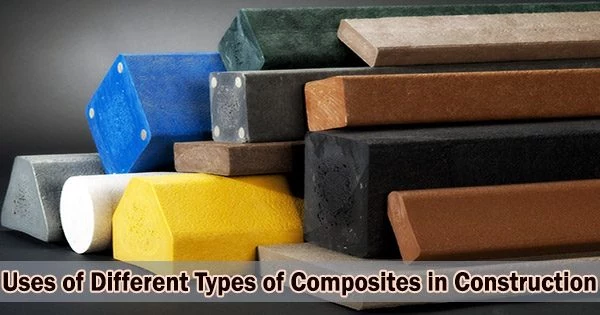

Composites are macro-scale materials made of two or more chemically different constituents with a clear interface between them and unique features that cannot be achieved by any constituent acting alone.

The basic materials can be divided into two categories: matrix and reinforcement. The reinforcement gives the matrix its unique mechanical and physical characteristics. The design possibilities are endless because there are so many different types of matrix and reinforcing materials available.

Miracle and Donaldson(2001) stated that the composites are categorized at two different levels. The first level of classification is based on the matrix constituent such as polymer matrix composite (PMCs), metal matrix composite (MMCs), and ceramic matrix composite (CMCs) whereas the second level of classification is derived from matrix constituent forms like particulate reinforced composite, flake composite, fiber-reinforced composite, and laminated composite.

Types of Composites in Construction

Composites are classified into two distinct levels; based on matrix constituents and their forms.

Composite Types Based on Matrix Constituents

There are three major types of composites based on matrix constituents. The matrix is typically a continuous phase across the component in each of these systems.

Polymer Matrix Composite (PMCs)

It is made up of a variety of brief or continuous fibers that are joined by an organic polymer matrix. The primary purpose of a polymer matrix composite is to transfer loads from one fiber to another through the matrix.

A few characteristics of polymer matrix composites include their light weight, high stiffness, high strength perpendicular to their reinforcements, abrasion resistance, and corrosion resistance.

Metal Matrix Composite (MMCs)

Since aluminum is less dense than iron and is therefore desired in the aerospace industry, it is typically used to make metal matrix composites in order to provide them enough strength. Continuous carbon, silicon carbide, or ceramic fibers are inserted in a metallic matrix to create this substance.

Most common metal matrix composites are aluminum matrix composites. Major benefits of aluminum matrix composites include higher wear resistance, lower density, and strong corrosion resistance in addition to increased specific strength, specific stiffness, and elevated temperature strength.

Ceramic Matrix Composite (CMCs)

These are materials consisting of a ceramic or carbon fiber surrounded by a ceramic matrix such as silicon carbide.

Composite Types Based on Matrix Constituents Forms –

Particulate Reinforced Composites

Hard particle components that are randomly dispersed in a softer matrix make up particulate reinforced composites. A particulate composite is an example of a metallic particle dispersed in metallic, polymeric, or ceramic matrices. Concrete with gravel embedded in the cement paste is a common particle composite.

Flake composites

This type of composite is produced by blending matrix material and thin flakes. Although the dispersion of the flakes in the matrix is random, it is still possible to align the flakes so that they form a more organized structure than particle composites.

Fiber Reinforced Composites (Fibrous Composites)

It is composed of strong and stiff fibers which are held together by a matrix. Due to their robust qualities, fibers serve as the main load-carrying component. When fibers begin to fail under severe stresses, the matrix acts as an agent to shift the loads from the broken fiber to the next fibers in the material.

One of the most significant properties of fibrous composites, enhanced strength relative to the individual constituents, is a result of this property of the matrix constituent.

Reinforcement composites are usually glass fibers, carbon fibers and aramid fibers. The majority of the time, fibers are low-density, high-strength materials that are both lightweight and easy to handle.

Laminated Composites

Laminated composites are made from completely bonded thin elementary layers. These layers might actually be composites, like a fibrous composite layer. The laminated composite material utilized in high-performance structures most frequently uses this kind of composite.

Applications

- In the aerospace sector, composite materials are frequently employed to build the structures of both military and commercial aircraft and spacecraft.

- Composites provide significant improvements in structural response and corrosion response.

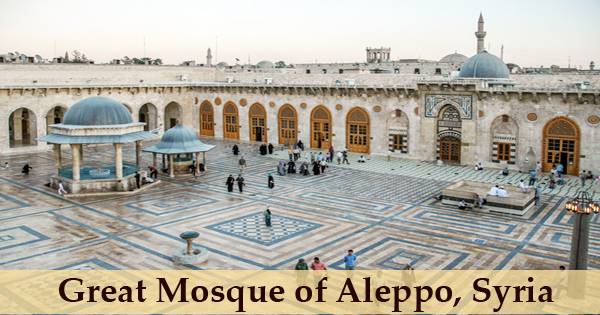

- Construction of structures such as Kodak exhibition pavilion, bridges, lighthouses, hydraulic construction, storage tanks, and door and window components

- Strengthening of deteriorated structures.

- Manufacturing of yacht, lifeboat, cruise ship, fishing boat.