Unlike traditional 3D printing, which uses a digital plan to create an object out of materials such as plastic or resin, 3D bioprinting creates biological parts and tissues out of living cells (bioinks).

Incorporating materials that allow printed constructs to morph numerous times in a preprogrammed or on-demand way in response to external signals can provide a fourth dimension shape alteration over time.

Bioprinting 4D constructions allows scientists to build complex structures that better resemble the form changes that occur during the growth, healing, and normal operation of genuine tissues.

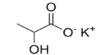

A new study published in the science journal Advanced Materials reveals the development of a new cell-laden bioink for bioprinting 4D constructions that comprises tightly packed, flake-shaped microgels and living cells.

The development of cell-rich bioconstructs that may alter shape under physiological settings is now possible thanks to this innovative approach.

Engineers from the University of Illinois Chicago constructed the bioink and tested prototype hydrogels for the study, titled “Jammed Micro-Flake Hydrogel for Four-Dimensional Living Cell Bioprinting.”

This is the first system that meets the demanding requirements of bioprinting 4D constructs: load living cells in bioinks, enable printing of large complex structures, trigger shape transformation under physiological conditions, support long-term cell viability and facilitate desired cell functions such as tissue regeneration.

Aixiang Ding

Their efforts yielded a range of complex bioconstructs with well-defined shapes and great cell survival, including the development of a 4D cartilage-like tissue. More complicated, multiple 3D-to-3D shape transformations in bioconstructs generated in a single printing are demonstrated in other designs.

“This bioink system provides the opportunity to print bioconstructs capable of achieving more sophisticated architectural changes over time than was previously possible. These cell-rich structures with pre-programmable and controllable shape morphing promise to better mimic the body’s natural developmental processes and could help scientists conduct more accurate studies of tissue morphogenesis and achieve greater advances in tissue engineering,” said study corresponding author Eben Alsberg, Richard and Loan Hill Chair, who has appointments in the departments of biomedical engineering, mechanical and industrial engineering, pharmacology and regenerative medicine, and orthopaedics.

Alsberg says the bioink advances previous technologies in several ways.

“The bioinks have what are called shear-thinning and rapid self-healing properties that enable smooth extrusion-based printing with high resolution and high fidelity without a supporting bath. The printed bioconstructs, after further stabilization by light-based crosslinking, remain intact while, for example, bending, twisting or undergoing any number of multiple deformations. With this system, cartilage-like tissues with complex shapes that evolve over time could be bioengineered,” Alsberg said.

“Another key achievement was engineering a system that enables fabrication of bioconstructs capable of undergoing complicated 3D-to-3D shape transformations.”

“This is the first system that meets the demanding requirements of bioprinting 4D constructs: load living cells in bioinks, enable printing of large complex structures, trigger shape transformation under physiological conditions, support long-term cell viability and facilitate desired cell functions such as tissue regeneration,” said Aixiang Ding, postdoctoral research associate at UIC and the first author of the paper.

“We are endeavoring to translate this system into clinical applications of tissue engineering, as there is a critical shortage of available donor tissues and organs.”

UIC’s Oju Jeon, David Cleveland, Kaelyn Gasvoda, Derrick Wells and Sang Jin Lee are co-authors of the paper. This work was supported by grants from the National Institute of Arthritis and Musculoskeletal and Skin Diseases (R01AR069564, R01AR066193) and the National Institute of Biomedical Imaging and Bioengineering (R01EB023907).