Thin-film solar cells are created by depositing one or more thin layers of photovoltaic material (thin films or TFs) onto a substrate such as glass, plastic, or metal. It is a type of solar cell distinguished by its thin and lightweight design. Thin-film solar cells, as opposed to traditional crystalline silicon solar cells, are created by depositing semiconductor materials in thin layers on various substrates. The photovoltaic effect allows these materials to convert sunlight directly into electricity.

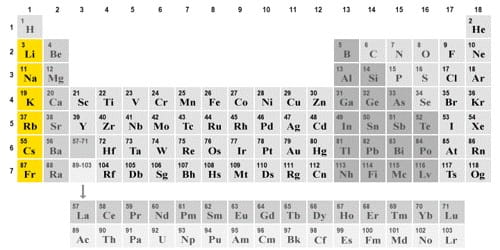

Thin-film solar cells are typically a few nanometers (nm) to a few microns (µm) thick–much thinner than the wafers used in conventional crystalline silicon (c-Si) based solar cells, which can be up to 200 µm thick. Thin-film solar cells are commercially used in several technologies, including cadmium telluride (CdTe), copper indium gallium diselenide (CIGS), and amorphous thin-film silicon (a-Si, TF-Si).

The majority of thin-film solar cells are second generation, with thin layers of well-studied materials such as amorphous silicon (a-Si), cadmium telluride (CdTe), copper indium gallium selenide (CIGS), or gallium arsenide (GaAs) being used. Third-generation or emerging solar cells are those made with newer, less established materials. This includes some cutting-edge thin-film solar cell technologies such as perovskite, dye-sensitized, quantum dot, organic, and CZTS.

There are several types of thin-film solar cells, each using different semiconductor materials. The most common types include:

- Amorphous Silicon (a-Si): Non-crystalline silicon is used to make amorphous silicon solar cells. They are the most commonly used type of thin-film solar cell in calculators, watches, and other small electronic devices, and they are the most commercially established type of thin-film solar cell.

- Cadmium Telluride (CdTe): CdTe thin-film solar cells are made from a cadmium and tellurium compound. Because of their low production costs and high efficiency, they have shown great promise for large-scale commercial applications.

- Copper Indium Gallium Selenide (CIGS): Copper, indium, gallium, and selenium are used to make CIGS thin-film solar cells. They are more efficient than amorphous silicon and more flexible, making them suitable for applications such as building-integrated photovoltaics and other non-traditional settings.

Thin-film solar cells have some advantages over traditional crystalline silicon solar cells, including:

- Lower material usage, which leads to reduced manufacturing costs.

- Flexibility, allowing for applications on curved surfaces and in lightweight, flexible modules.

- Enhanced performance under diffuse or low-light conditions, making them more suitable for certain environments.

- Lower energy payback time, meaning they recoup the energy used in their manufacturing faster than traditional solar cells.

Thin-film solar cells, on the other hand, have lower conversion efficiencies than crystalline silicon solar cells. As a result, larger installation areas are typically required to produce the same amount of electricity. Nonetheless, ongoing research and development efforts aim to improve thin-film solar cell efficiency and make them more competitive in the renewable energy market.