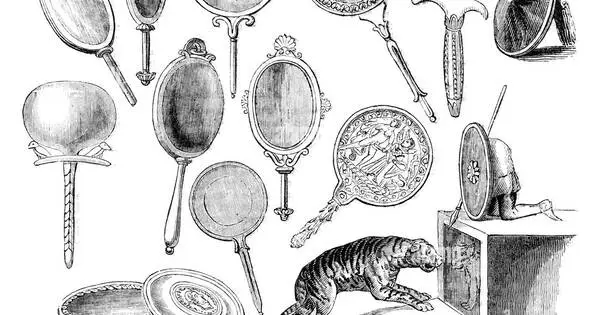

Speculum metal is a white brittle alloy composed of around two-thirds copper and one-third tin that may be polished to produce a highly reflecting surface. It was traditionally used to manufacture a variety of mirrors ranging from personal grooming aids to optical equipment until being supplanted by more sophisticated materials such as metal-coated glass mirrors.

Large speculum metal mirrors are difficult to produce, and the alloy is prone to tarnish, necessitating periodic re-polishing. However, until to the advent of glass silvering, it was the only practicable alternative for huge mirrors in high-precision optical equipment between the mid-17th and mid-19th centuries.

Speculum metal was notable for its usage in the metal mirrors of reflecting telescopes, such as Newton’s telescope, the Leviathan of Parsonstown, and William Herschel’s telescope, which was used to find the planet Uranus. One major disadvantage of using it in telescopes is that the mirrors could not reflect as much light as modern mirrors and tarnished quickly.

Overview

Speculum metal mixes are typically two parts copper to one part tin with a trace of arsenic, while various mixtures comprising silver, lead, or zinc are available. Making highly hard white high luster metal out of bronze-type high-tin alloys may date back more than 2000 years in China, but it could also be a Western civilization creation. These metals were employed in sculpture as well as to construct more effective mirrors than the more usual yellow, easily deteriorating bronze mirrors. Mirrors made of speculum metal, or any valuable metal, were uncommon and exclusively owned by the wealthy at the time.

Use in telescopes

In early modern Europe, speculum metal was used as the only known suitable reflecting surface for mirrors in reflecting telescopes. Unlike domestic mirrors, where the reflecting metal layer is placed on the back of a glass pane and protected with varnish, precision optical equipment such as telescopes require first surface mirrors that can be machined and polished into complex shapes such as parabolic reflectors. For nearly 200 years, the only mirror substance capable of this purpose was speculum metal. James Gregory’s Gregorian telescope, one of the oldest designs, could not be built because Gregory could not find a craftsman capable of producing the complicated speculum mirrors required for the design.

In 1668, Isaac Newton became the first person to successfully construct a reflecting telescope. His first reflecting telescope included a 33-mm diameter speculum metal primary mirror of his own design. Newton was also faced with the challenge of creating the intricate parabolic shape required to make the image, but he simply settled on a spherical shape. The composition of speculum metal was developed further and was utilized in numerous designs of reflecting telescopes throughout the 1700s and 1800s. The optimal ratio was roughly 68.21 percent copper to 31.7 percent tin; more copper made the metal yellower, and more tin made the metal bluer. For tarnishing resistance, ratios of up to 45 percent tin were utilized.