Sheffield plate is a copper-plated with silver by rolling and edging with silver film and ribbon, especially as produced in Sheffield between 1760 and 1840. It is a layered combination of silver and copper that was used for many years to produce a wide range of household articles. Almost every article made in sterling silver was also crafted by Sheffield makers, who used this manufacturing process to produce nearly identical wares at far less cost. The technique was discovered about 1742 by Thomas Boulsover, a Sheffield cutler, who noted that the combination of fused silver and copper retained all the ductility possessed by both metals and acted as one in response to manipulation.

History

The material was accidentally invented by Thomas Boulsover, of Sheffield’s Cutlers Company, in 1743. While trying to repair the handle of a customer’s decorative knife, he heated it too much and the silver started to melt. Boulsover discovered that silver and copper could transform into a sheet that could be fashioned into objects that look like sterling silver. When he examined the damaged handle, he noticed that the silver and copper had fused together very strongly. Experiments showed that the two metals behaved as one when he tried to reshape them, even though he could clearly see the two different layers.

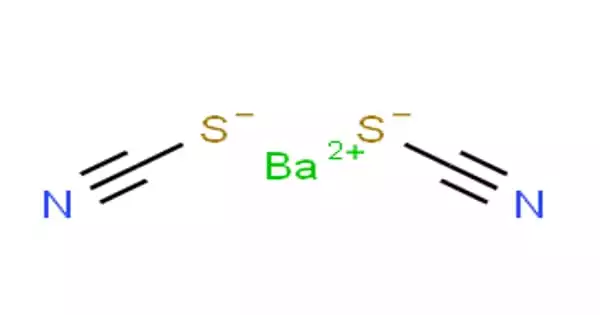

Sheffield plate was produced as follows – an ingot of copper, slightly alloyed with zinc and lead, was covered on both top and bottom with a sheet of silver and fired. When the silver began to melt, the ingot was removed from the furnace, cooled, and rolled.

Sub: “double sandwich” form of the Sheffield plate

Double sandwich form

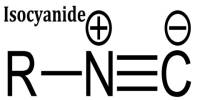

The “double sandwich” form of the Sheffield plate was developed around 1770. Used for pieces such as bowls and mugs that had a visible interior, it consisted of a sheet of silver each side of a piece of copper; early manufacturers applied a film of solder over the bare edge of copper although such pieces are very rare. The traits of the Sheffield silver plate were strength, durability, and good looks. Demand soon exceeded supply and a number of manufacturers began to make new pieces, reproducing original designs by electroplating on copper.

Nickel silver

Sheffield Plate is a clad plate made by rolling and fusing a thin covering of silver on either side of a copper sheet. Following the invention of German silver (60% copper, 20% nickel, and 20% zinc), around 1820, it was found that this new material also fused well with sheet silver and provided a suitable base metal for the Sheffield process. Being much harder than copper, it was used from the mid-1830s but only for articles such as trays or cylindrical items that did not require complex shaping.

Usage

It became an important industry because objects could be made of Sheffield plate much more cheaply than if they were made of silver. Items produced in Sheffield plate included buttons, caddy spoons, fish slices, serving utensils, candlesticks and other lighting devices, coffee and tea sets, serving dishes and trays, tankards, and pitchers, and larger items such as soup tureens and hot-water urns.