What is Textile?

What is Fiber?

What is Textile Fiber?

Essential Requirements of Textile Fibers

To be treated as Textile fiber, a fiber must have these properties-

- Spun ability.

- Sufficient strength.

- Elasticity and flexibility.

- Fineness.

- Dye ability.

Fibers And Filaments

- FIBER : Fibers / Staple fibers- are the fibers of limited length (1 – 8 inch approx.). To make a continuous length of yarn from staple fiber , they must be twisted together. Basically this term used for the Natural fibers.

- FILAMENT : Filament fibers are of continuous length (more than 8 inch and continuous). That is to say the fabrics made from filament fibers are more easier to made as the filament length are continuous.

Basically this term used for the Man made fibers.

Note: ( Silk is the only Natural fiber found in Filament form)

Classification Of Fibers

| Natural fiber | Man-made fiber |

| Directly Comes from nature. | Made from nature. |

| The length can not be controlled. | length can be controlled. |

| Comfortable and good for health. | Quite Uncomfortable and not sogood for health. |

| It is expensive compare to MMF. | It is not expensive compare to NF. |

| We have to depend on nature forits production. | For production, no dependence onnature is necessary. |

| It is not much favorable forfinishing. | It is favorable for finishing. |

| Example – cotton, silk, etc. | Example – Polyester, Nylon, etc. |

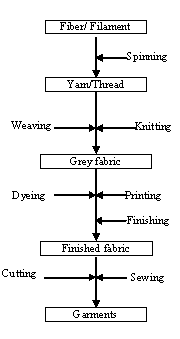

Process Sequence Of Textile:

Properties of Fiber

- Physical Properties

- Chemical Properties

Physical Properties

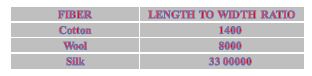

- Length To Width Ratio : Fibrous material must possess adequate staple or fiber length and the length must be considerably higher (1000 times) then the width of the fiber.

Length to width ratio of some typical fiber as follows :

- Fiber Strength:

Strength of any material is determined by the breaking strength (that is tenacity strength) which express as force per unit cross-sectional area. With this term (strength / tensile strength) we may describe the ability of a bundle of fiber or yarn to resist breakage under tension / load.

In case of describing the strength of individual fiber the term tenacity is usually used.

Tenacity = breaking load / mass per unit length

- Elasticity & Elastic Recovery

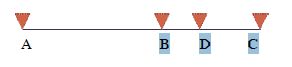

The ability of a fiber to come back to its original length after removing tension is called Elasticity. Elastic Recovery is the mathematical measurement of Elasticity. Here in this figure, if AB is original length, BC is the extension & CD is the recovery, then Elastic recovery of this fiber will be,

(CD*100/BC)

- Fiber Fineness & Micronaire value :

The term ‘fineness’ describes the quality of a fiber. It is calculated in Micronaire value. By this, we can know how fine a fiber is.

Micronaire value

Micrograms/ inch. The average weight of one inch length of fiber, expressed in micrograms.

Cotton fiber micronaire value is generally 3.7-4.2.

- Resiliency : This is the ability of a fiber to bounce back or return to its original shape after deformation. It can be after compression, bending, extension, etc.

- Flexibility : It is one of the essential property of textile fiber . The fibers should be sufficient by pliable , then only it can be wrapped around another fiber during spinning . Many substance in nature resemble fibrous forms but they are not practical fibers as they are stiff and brittle .

- Uniformity: This is the similarity of the fibers. Such as, if length of some fibers are same we will say uniform length, if strength is similar, we will say uniform strength.

- Cohesiveness: It is the ability of the fibers to cling together during spinning depends on crimp and twist.

- Crimp : It refers to the waves or bends that take place along the length of a fiber. It increases cohesiveness & resiliency

Chemical Properties

- Amorphousness: Amorphous orientation of polymers within the polymer system of any fiber is called the amorphous region. In amorphous regions, the polymers are oriented or aligned at random.

- Crystallinity: Crystalline orientation of polymers within the polymer system of any fiber is called the crystalline region. In crystalline regions the polymers are oriented into more or less parallel order.

- Dye ability: It is the ability of fibers to be dyed i.e. to get colored.

- Behavior to Water: Water is very important to determine the properties of fibers. According to the behavior of fibers with water, fibers are classified into two groups –hydrophobic and hydrophilic. Water is used in process like scouring, dyeing.

- Behavior to Acid: Textile fibers and materials are subjected to acids in various processing like bleaching. The different kinds of fibers react differently with acids. The acid must be chosen properly to use different process so that it doesn’t make any harm to the fiber but brings the required change perfectly.

- Behavior to Alkali: Different kinds of fibers behave differently with different alkalis in different situations. For example, Caustic soda in dilute solution and low temperature dissolved the wool fibers. But no effect on cotton.

Fiber Absorbency : Moisture Regain & Moisture Content

The ability of a fiber to absorb moisture is called Fiber Absorbency.

It is expressed by “Moisture Regain%” and “Moisture Content%.”

Fiber Absorbency : Moisture Regain & Moisture Content

- Moisture Regain%

= (Conditioned weight-Dry weight)*100

Dry weight

- Moisture Content%

= (Conditioned weight-Dry weight)*100

Conditioned weight

Other Properties

- Effect on Heat:

Textile fibers are subjected to heat in dyeing, drying, steaming, calendaring, pressuring and other operations. Some fibers become tough under heat such as Rayon, where as some burn under heat such as flax, cotton, jute, etc.

- Effect on Sunlight:

Sunlight reacts differently with different fibers and fabrics. For example, white fabrics become faded in various degrees. Again black absorbs more suns heat than the white one.