Washington State University researchers successfully tested a new method for producing sustainable jet fuel from lignin-based agricultural waste. The team’s findings, published in the journal Fuel Processing Technology, demonstrated a continuous method that directly converts lignin polymers, one of the primary components of plant cells, into a type of jet fuel that could help improve the performance of sustainably produced aviation fuels.

“Our achievement brings this technology one step closer to real-world use by providing data that allows us to better assess its feasibility for commercial aviation,” said lead scientist Bin Yang, a professor at WSU’s Department of Biological Systems Engineering.

A class of structural molecules that make plants tough and woody, lignin is derived from corn stover – the stalks, cobs and leaves left after harvest – and other agricultural byproducts.

Our achievement brings this technology one step closer to real-world use by providing data that allows us to better assess its feasibility for commercial aviation.

Bin Yang

The researchers developed a process known as “simultaneous depolymerization and hydrodeoxygenation,” which breaks down the lignin polymer while also removing oxygen to produce lignin-based jet fuel. The scientists produced the fuel at their Richland facility by introducing dissolved lignin polymer into a continuous hydrotreating reactor.

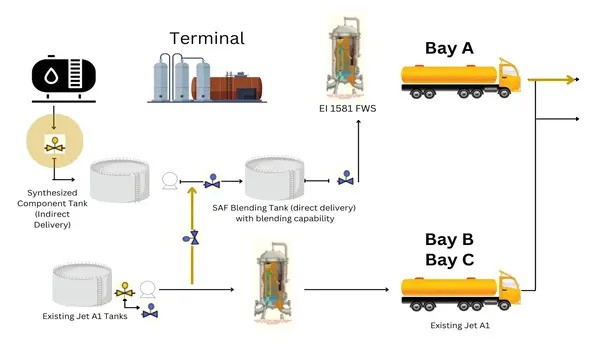

In 2019, global aviation fuel consumption reached a record high of about 100 billion gallons, and demand is likely to rise in the next decades. Sustainable aviation fuels made from plant-based biomass may help reduce aviation’s carbon footprint, reduce contrails, and meet international carbon neutrality targets.

Lignin-based jet fuel could make sustainable fuels cleaner and more easily usable in jet engines. Thanks to their density, efficiency, and seal-swelling characteristics, hydrocarbons catalyzed from lignin could effectively replace fossil fuel-derived compounds called aromatics. Associated with contrails and climate impacts, aromatics remain in use because they enhance fuel density and help swell O-rings in metal-to-metal joints.

This study was the team’s first successful test of a continuous technique that is more suitable for commercial manufacturing. The investigation also used a less processed and less expensive form of lignin obtained from maize stover, known as “technical lignin,” in contrast to previous research that used extracted lignin bio-oil.

The researchers’ findings indicate that lignin is a possible source of aromatic-replacing cycloalkanes and other valuable fuel molecules.

“The aviation industry wants to produce 100% renewable aviation fuel,” said Josh Heyne, a study team member and co-director of the WSU-PNNL Bioproducts Institute. “Lignin-based jet fuel complements existing technologies by, for example, increasing the density of fuel blends.”

Offering reduced emissions, lignin-based fuel could ultimately make sustainable aviation fuels fully “drop-in” capable, meaning they can be used with all existing engines, infrastructure and aircraft like existing fossil-derived aviation fuel.

“We’re working to create an effective, commercially relevant technology for a complementary blend component that can achieve the 100% drop-in goal,” Heyne said.