Surface engineering is a branch of materials science that focuses on the surface of solid matter. It is an area of materials science and engineering that focuses on changing the surface properties of materials while keeping the bulk properties unchanged. It finds use in chemistry, mechanical engineering, and electrical engineering (especially in semiconductor fabrication).

Surface engineering’s purpose is to increase the performance, durability, and functionality of materials in a variety of applications. It is a critical field having applications in automotive, aircraft, electronics, and manufacturing. Solids are made up of a bulk material that is covered by a surface. The surface phase is the surface that surrounds the bulk substance. It serves as a gateway to the surrounding surroundings. The bulk material in a solid is called the bulk phase.

The surface phase of a solid interacts with its surroundings. This interaction has the potential to deteriorate the surface phase over time. Wear, corrosion, fatigue, and creep can all cause environmental degradation of the surface phase over time.

Key aspects of surface engineering include:

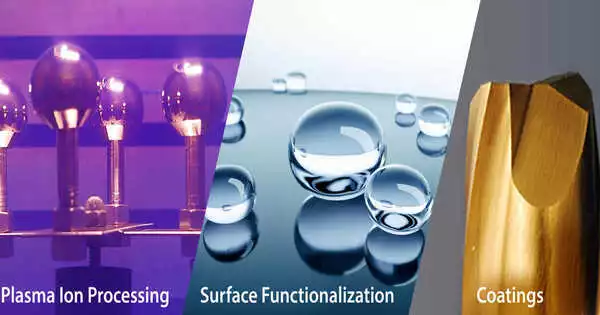

- Surface Modification: Surface engineering approaches seek to modify the surface of materials in order to obtain specified qualities or functionalities. This can include altering the surface’s chemical composition, structure, or physical qualities.

- Surface Coatings: Coatings are frequently applied to materials in order to improve their surface qualities. Painting, plating, thermal spraying, and chemical vapor deposition are all common coating processes. Corrosion resistance, wear resistance, lubrication, and ornamental finishes can all be provided by coatings.

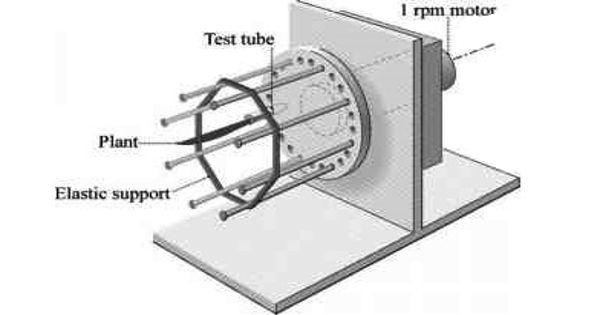

- Surface Heat Treatment: Heat treatment procedures such as carburizing, nitriding, and annealing are used to change the microstructure and mechanical properties of materials’ surface layers. Heat treatment can increase hardness, toughness, and wear resistance.

- Surface Cleaning and Preparation: Proper cleaning and preparation of surfaces are essential for ensuring good adhesion of coatings and achieving the desired surface properties. Surface treatments like sandblasting and chemical etching are used to prepare surfaces.

- Surface Analysis: Surface engineering often involves the use of analytical techniques like microscopy, spectroscopy, and surface profilometry to study and characterize surface properties and modifications.

- Tribology: Tribology is the study of friction, wear, and lubrication. Surface engineering plays a vital role in designing materials and coatings that reduce friction and wear, thereby increasing the lifespan and efficiency of mechanical components.

- Biomaterials: In the field of medicine and biotechnology, surface engineering is used to develop biocompatible materials and coatings for implants, medical devices, and drug delivery systems.

Surface engineering entails changing the properties of the surface phase to reduce degradation over time. This is achieved by hardening the surface to the environment in which it will be used. It provides a low-cost material for strong design. Plating technologies, nano and emerging technologies, and surface engineering, characterization, and testing are examples of topics that demonstrate the broad nature of the discipline of surface engineering.

Overall, surface engineering is a multidisciplinary field that uses chemistry, physics, materials science, and engineering to adapt material surfaces for specific purposes, ultimately enhancing product and component performance and lifetime.