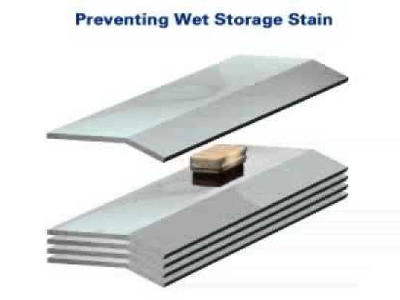

Wet storage stain describes the white, generally powder-like substance that can form on the surface of a galvanized article. It is a type of zinc corrosion. It is called wet storage stain because it occurs when a fresh zinc surface is stored in a wet environment with limited oxygen and carbon dioxide sources; the restriction in the air is usually due to the items being stacked on one another or otherwise stored in close quarters. This type of corrosion does not usually occur to zinc surfaces that have had time to form their normal layers of corrosion protection. It is found most often on stacked and bundled items, such as galvanized sheets, plates, angles, bars, and pipes.

In Chemistry

Wet storage stain is a white, crumbly, and porous substance that is a mixture of three chemical compounds: 2ZnCO3·3Zn(OH)2, ZnO, and β-Zn(OH)2. Underneath the white coating is usually a dark gray surface. White spots resulting from storage, mainly basic zinc oxide resulting from storage in damp conditions after galvanization, do not constitute grounds for rejection either. The corrosion product is very voluminous; it is approximately 100 times greater in volume than the zinc consumed.

Wet storage stain only occurs in situations where there is a lack of oxygen or carbon dioxide because it usually forms zinc oxide and zinc hydroxide in open-air environments. Wet storage stain does not affect the quality or the useful life of galvanized materials and it disappears spontaneously after a while with exposure to air. It does tarnish the material.

Pic: removed in the galvanized coating to form the zinc patina

Removal

Medium and heavy wet storage stain must be removed in order for the galvanized coating to form the zinc patina, otherwise, the service life of the zinc coating and underlying steel can be affected. To stop the corrosion from continuing the object just needs to be aired out to remove any moisture and allow the normal layer of protection to form. When the material is exposed to air, the protective sink patina forms gradually, and most or all of the wet storage stain will disappear in time. Washing and a wire brush will remove most of the corrosion. For complete removal, 10% acetic acid or a mixture of polishing chalk and 20–40% NaOH can be used.

Prevention

Treatment of wet storage stain begins with drying the galvanized surface. As long as water remains on the zinc surface and airflow is limited, the corrosion mechanism responsible for wet storage stain will continue and can damage the zinc coating and underlying steel. Wet storage stain can be prevented for a limited amount of time by coating in light oil, chromate conversion coatings, or phosphate conversion coatings. A more permanent solution is to paint the surface. The extent of the damage caused by wet storage stain depends on the duration of exposure to retained moisture with little airflow over the galvanized coating.