Surface modification is the act of changing a material’s surface by introducing physical, chemical, or biological properties that differ from those found on the material’s original surface. It is the process of changing the properties or characteristics of a material’s surface while leaving its bulk attributes mostly unaltered. This can be done for a variety of reasons, like as increasing the material’s performance, increasing its endurance, or making it more suitable with specific uses.

Surface modification techniques are widely employed in a wide range of industries, including manufacturing, electronics, biomedicine, and others. This modification is often applied to solid materials, but examples of the alteration to the surface of certain liquids can be found. Different approaches can be used to modify the surface in order to change a variety of surface properties such as roughness, hydrophilicity, surface charge, surface energy, biocompatibility, and reactivity.

Here are some common methods and reasons for surface modification:

- Chemical Modification: Chemical etching, surface grafting, and chemical vapor deposition are all methods for modifying the chemical composition of the surface. For example, you can make a surface more hydrophilic or hydrophobic by inserting functional groups.

- Physical Modification: Surfaces can be altered physically without changing their chemical composition. Sandblasting, shot peening, and laser ablation can be used to roughen or smoothen the surface, which can affect attributes like as adhesion, friction, and optical properties.

- Coating and Thin Films: Coatings or thin films can provide protection, corrosion resistance, or specialized qualities such as anti-reflective, anti-scratch, or conductive coatings when applied to a surface. Painting, plating, and chemical vapor deposition are a few examples.

- Ion Implantation: This involves bombarding the surface with high-energy ions to introduce dopants or change the crystal structure of the material, thereby altering its electrical or mechanical properties.

- Heat Treatment: Annealing or surface hardening through heat treatment can improve the mechanical properties of a material. For example, carburizing can increase the surface hardness of steel.

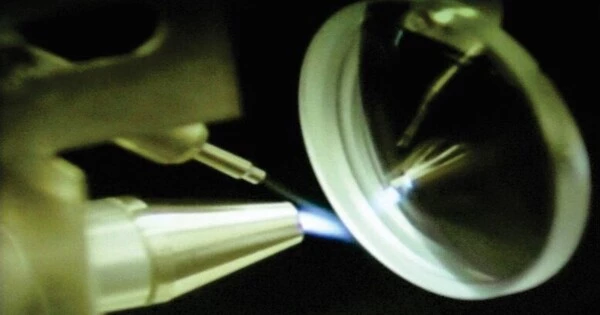

- Plasma Treatment: Plasma can be used to modify the surface by adding reactive groups, removing impurities, or changing the surface energy. It’s very frequent in the semiconductor sector.

- Biomedical Surface Modification: Surface modification might be critical in biomedical applications. Implantable medical devices, for example, may be subjected to surface treatments to improve biocompatibility, minimize the risk of infection, or encourage tissue integration.

Surface modification is a flexible field with applications in many sectors, and the method used is determined by the application’s specific requirements and the material involved. It has the potential to increase product performance, lifetime, and functionality for a wide range of materials and products.