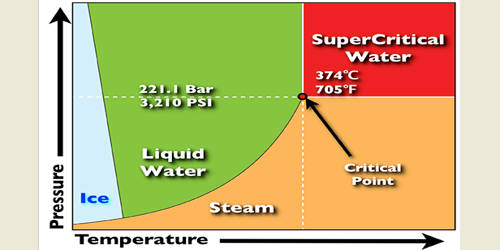

Supercritical water oxidation (SCWO) is a process that occurs in the water at temperatures and pressures above a mixture’s thermodynamic critical point. It is a promising, environment-friendly technology to efficiently deal with a wide variety of organic wastes such as wastewaters, industrial and municipal sludge, etc. Under these conditions, water becomes fluid with unique properties that can be used to advantage in the destruction of hazardous wastes such as PCBs. This process has been extensively studied for decades from laboratory scale studies of model compounds to several demonstration and industrial plants under construction worldwide. This process has been extensively applied to many model compounds and real wastewaters at a laboratory scale.

Supercritical water (SCW) refers to water whose temperature and pressure are above its critical point (374.15°C, 22.1 MPa). The fluid has a density between that of water vapor and liquid at standard conditions and exhibits high gas-like diffusion rates along with high liquid-like collision rates. The physical properties of SCW such as density, viscosity, dielectric constant, hydrogen bonding, and the ionic product is vastly different from those of normal water and steam. Furthermore, the application of this technology to industrial wastewaters has the two main drawbacks of corrosion and salt deposition, and some other problems to be solved related to the management of biphasic wastes, presence of suspended solids, high costs, etc., so currently the industrial scale-up and commercialization of the process are still subject to difficulties. To overcome these technical difficulties, research focused on solving these problems is necessary. The reversed solubility also causes salts to precipitate out of solution, meaning they can be treated using conventional methods for solid-waste residuals. Efficient oxidation reactions occur at low temperature (400-650 °C) with reduced NOx production.

Supercritical water oxidation (SCWO) is a powerful green technology to treat hazardous wastewaters. SCWO can be classified as green chemistry or as a Clean Technology. The elevated pressures and temperatures required for SCWO are routinely encountered in industrial applications such as petroleum refining and chemical synthesis.

Commercial applications

This process can utilize different reactors to reduce the operational problems related to solids precipitation and corrosion. Several companies in the United States are working to commercialize supercritical reactors to destroy hazardous wastes. In Japan, a number of commercial SCWO applications exist, among them one unit for treatment of halogenated waste built by Organo. In Korea, two commercial size units have been built by Hanwha.

In Europe, Chematur Engineering AB of Sweden commercialized the SCWO technology for the treatment of spent chemical catalysts to recover the precious metal, the AquaCat process. The unit has been built for Johnson Matthey in the UK.

Turbo systems Engineering (California, USA) is actively commercializing its patented transpiring wall SCWO reactor (“TWR”) with a focus on renewable energy applications.