The Sendzimir process is a surface coating process where the workpiece is dipped into a bath of zinc and aluminum to form a surface. This process named after Tadeusz Sendzimir is used to galvanize a steel strip by using a small amount of aluminum in the zinc bath and producing a coating with essentially no iron-zinc alloy. The surface is prepared by using heat treatments able to burn and remove oil emulsion residues and reduce the oxides in an inert atmosphere. Due to the high yield and good galvanizing quality of the Sendzimir method, this method has been widely used.

The Sendzimir method is mainly a word appearing on galvanized steel pipes and is also the development of galvanized steel pipes. It combines the annealing process with the gi pipe zinc process.

The process guarantees high resistance and durability characteristics. It is a galvanizing process in which controlled surface oxidation of the material is followed by reduction of the thin oxide layer in an atmosphere maintained right until immersion in the molten zinc bath, so eliminating pickling and fluxing. About 75% of hydrogen was needed in the original Sendzimir process but all the newer nonoxidizing methods of degreasing require only 7–15%.

The in-line annealing mainly consists of an oxidation furnace and a reduction furnace. The workpiece is dipped into a bath of molten zinc and aluminum. The melt secures and creates a coating on the workpiece which is then taken out of the bath and drained off the excess melt. The strip steel is directly heated to about 450 degrees in the oxidation furnace, and the rolling oil remaining on the strip surface is burned off to purify the surface. Depending on the design, the part can be given subsequent processing required to remove accumulations of the melt or sharp spikes. The coating produced in this method is somewhat more ductile than that created by conventional hot-dip galvanizing because of the addition of aluminum. Finally, the zinc pot is galvanized without contact with the air. This is the Sendzimir method.

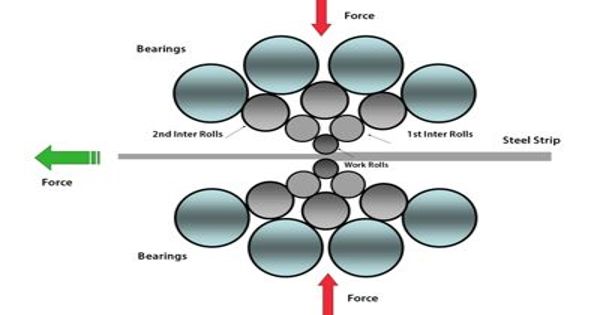

The rolling of hot steel slabs using a Sendzimir mill requires a much smaller operational area than a continuous hot strip mill. This milling process is not recommended for heavy-duty running surfaces such as crane rail. However, since the strip steel is not preheated, it enters the reduction furnace, which undoubtedly increases the heat load of the reduction furnace and affects the life of the furnace. Therefore, this method has not been widely used.

Information Source: