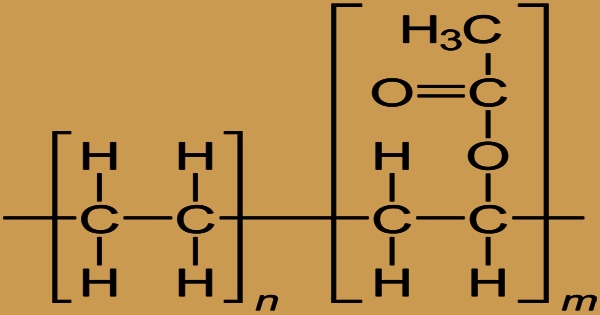

Ethylene-vinyl acetate (EVA), sometimes known as poly ethylene-vinyl acetate (PEVA), is a thermoplastic that is very elastic and strong, with great clarity and gloss and no odor. It’s an ethylene and vinyl acetate copolymer. The percentage of vinyl acetate in the final product ranges from 10 to 40%, with the rest being ethylene. Ethylene-vinyl acetate is accessible in pellet or powder form as white waxy solids. Translucent films are available. There are three varieties of EVA copolymer, each with a different amount of vinyl acetate (VA) and a distinct manner of using the ingredients.

Low cost, great adhesion to various polar and nonporous substrates, strong flex-crack and puncture resistance, as well as good hot-tack and heat-sealing, are just a few of the benefits of EVA. Vinyl acetate modified polyethylene refers to an EVA copolymer with a low percentage of VA (about 4%). It’s a copolymer that’s used to make thermoplastics in the same way as low-density polyethylene is. It has some of the characteristics of low-density polyethylene, but with added gloss (which is helpful for the film), softness, and flexibility. The substance is typically regarded as non-toxic.

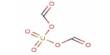

Random ethylene-vinyl acetate copolymers of various molecular weights can be made via high-pressure radical polymerization, bulk continuous polymerization, or solution polymerization. The thermoplastic ethylene-vinyl acetate copolymer (EVA copolymer) is a thermoplastic elastomer material that is based on a medium percentage of VA (about 4 to 30 percent). It is not vulcanized, but it has some rubber or plasticized polyvinyl chloride characteristics, especially at the higher end of the spectrum. In laminated transdermal drug delivery systems, ethylene-vinyl acetate copolymers are utilized as membranes and backings. They can also be used as components in transdermal systems’ backings.

Both filled and unfilled EVA materials have good low-temperature properties and are tough. Hot melt adhesives are made from materials containing around 11 percent VA. For the regulated administration of atenolol, triprolidine, and furosemide, EVA copolymers have been demonstrated to be an effective matrix and membrane. Using ethylene-vinyl acetate copolymers and plasticizers, a method for the controlled release of atenolol can be further developed. This thermoplastic resin is usually copolymerized with other resins, such as LDPE and LLDPE, or used as part of a multilayer film. EVA is found in blends and copolymers in percentages ranging from 2% to 25%.

Ethylene-vinyl acetate rubber is an EVA copolymer with a high percentage of VA (more than 60%). It improves the clarity and sealability of olefins (LDPE/LLDPE), whereas a larger proportion of EVA is frequently employed to lower the melting point and improve low-temperature performance. EVA is an elastomeric polymer that generates materials that are soft and flexible like “rubber.” The material offers high clarity and gloss, as well as low-temperature durability, stress-crack resistance, waterproof hot-melt adhesive characteristics, and UV resistance.

EVA has a strong vinegar-like odor and is competitive in many electrical applications with rubber and vinyl polymer materials. It is mostly utilized as a membrane or film backing in topical medicinal applications. It is generally thought to be a nontoxic and nonirritant excipient. EVA copolymers comprising between 10% and 30% vinyl acetate are utilized in a variety of packaging and plastic products applications. EVA is also utilized as a medication delivery method in biomedical engineering applications. In an organic solvent, the polymer is dissolved (such as dichloromethane).

Sealants are used in meat and dairy packaging structures, footwear, wire, and cable insulation, pipelines, toys, corks, photovoltaic encapsulation, medical packaging, hot melt adhesives, and glass lamination to increase impact resistance, among other uses. EVA slippers and sandals are popular because they are lightweight, flexible, odorless, glossy, and less expensive than real rubber. EVA is used to make the handles on the rod-butt end of fishing rods. EVA may be used to replace cork in a variety of applications.

Under normal conditions, ethylene-vinyl acetate (EVA) copolymers are stable and should be stored in a cold, dry area. EVA copolymer films should be kept at a temperature of 0–30°C with a relative humidity of less than 75%. EVA foam has been more popular in the cosplay community in recent years, owing to its simplicity of use, durability, and comfort when compared to traditional plastic-based costumes. Flower-making foam is a thin, flexible sheet of EVA that is used by artists and crafters to create fake flowers. These foams are sold as raw sheets that may be cut into the correct petal shape and then ironed together to create fake flowers.

Information Sources: