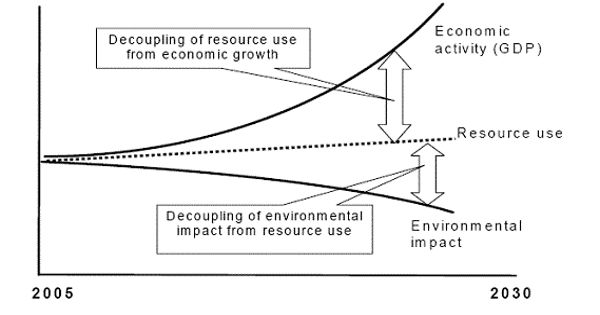

The University of California, Davis, in collaboration with the Mars Advanced Research Institute, has announced a significant advance in the creation of low-calorie sugar alternatives such as allulose. This discovery may aid in overcoming one of the key barriers to the widespread adoption of these alternatives: production costs.

Allulose, also known as D-psicose, is a naturally occurring uncommon sugar that can be used instead of sucrose (table sugar). It has a comparable taste, texture, and usefulness, making it an appealing option for people looking to cut back on sugar. Researchers have devised a method for high-yield and high-purity manufacture through precision fermentation by stimulating a natural process in a bacterium. This breakthrough has the potential to significantly improve the pricing and accessibility of these products.

Allulose has about 70% of the flavor and sweetness of sucrose while being slightly digested as it goes through the body. Individuals can minimize their calorie consumption from sugar while still satisfying their craving for sweet flavors by putting them into food products. Furthermore, allulose has a negligible influence on blood glucose and insulin levels.

Allulose is a great sugar substitute, but we haven’t found a cost-effective way to make it. Our new method is efficient, economically feasible and could be scaled up for commercial production.

Shota Atsumi

“Allulose is a great sugar substitute, but we haven’t found a cost-effective way to make it,” said Shota Atsumi, a UC Davis chemical professor and corresponding author on the article published in npj Science of Food. “Our new method is efficient, economically feasible, and could be scaled up for commercial production.”

Understanding the chemistry and manufacturing processes involved in developing a scalable production approach for a low-calorie sugar substitute is required. Depending on the precise qualities and characteristics of the desired sugar substitute, several potential approaches can be investigated.

The novel method provides a theoretical yield of more than 99% with great purity, requiring just minimal processing to extract the desired product. Current allulose manufacturing methods are typically limited to significantly lower levels of yield and purity, necessitating the use of costly separation procedures to separate allulose from the glucose and fructose starting materials.

Redirecting existing process

Atsumi, Ph.D. candidate Jayce Taylor, Professor Justin Siegel, and a group of colleagues from the Department of Chemistry and the Mars Advanced Research Institute sought a more efficient method of producing allulose. They discovered an industrial microbe that possesses the enzymes required to produce allulose but does not use them in this manner. They were able to change the metabolism of the creature so that the cells converted glucose into allulose. The cells eat all of the glucose that is fed to them and convert it to allulose with a notable concentration, yield of more than 60%, and purity of more than 95%, exceeding conventional production methods.

“Once flux was redirected, it turns out the cells have everything they need to do it; they just needed to be turned on and undesired pathways turned off,” Atsumi said.

UC Davis has filed patent applications on the process and modified organisms. Researchers are working with a commercial partner to discuss scaling up the process.