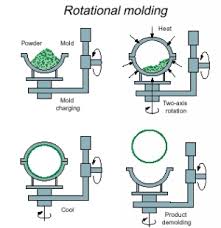

Rotational Molding involves a heated hollow mold which is filled with a new charge or photo weight of product. It is subsequently slowly rotated creating the softened product to disperse and adhere to the walls of the mold. In order to keep even thickness throughout the part, the mold continues to rotate constantly during the heating phase also to avoid sagging as well as deformation also over the cooling phase. Simplicity and cheaper tooling enhance the wonder of rotational molding. And they also make it less difficult to get any project off the soil. Parts can end up being prototyped at sensible cost so a design can be tweaked to utmost efficiency.

Rotational Molding