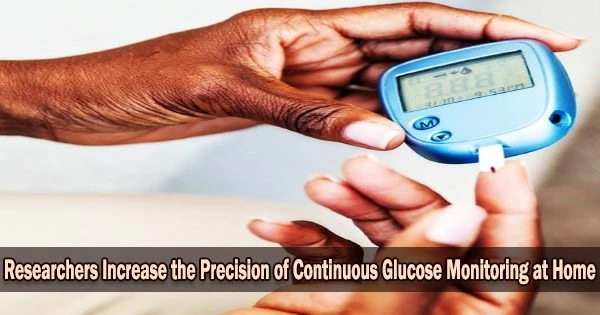

For diabetics, home-based continuous glucose monitoring has always required a trade-off between mobility, affordability, and ease of use for a slightly lower sensitivity and consequently accuracy when compared to systems in clinics or hospitals. Now, a group of scientists has created a biosensor for these monitors that uses gold nanospheres (AuNSs) and “zero-dimensional” quantum dots (QDs) and does not have to give up precision.

A paper describing the biosensor design and its enhanced performance appeared in the journal Nano Research on Nov. 9, 2022.

People with diabetes have benefited greatly from the advancement of continuous glucose monitoring (CGM) technology in recent years. The always-on CGM systems’ real-time, quick, and accurate detection of glucose levels has greatly improved diabetic care compared to pre-meal and pre-bedtime blood sugar tests.

Glucose trends are easier to track, making dietary, exercise, and medication changes to a diabetic care plan easier to apply throughout the day. Alarms sound when glucose levels soar or plummet, informing the person or notifying parents, partners, or carers.

Typically, CGMs operate by measuring the level of glucose in the intercellular fluid using a small biosensor inserted beneath the skin. Every few minutes, this sensor analyzes these levels and relays the results to a monitor. Additionally, an insulin pump can be attached to the monitor.

The detection of glucose can be accomplished using a number of methods, including as colorimetry, infrared spectroscopy, fluorescence spectroscopy, and mass spectrometry. However, electrochemical glucose detection is the most generally used method for usage at home rather than in a clinic or hospital due to its quick reaction, simplicity of use, low cost, and mobility.

“It also has decent sensitivity, but not excellent sensitivity,” said Huan Liu, a microelectronics specialist with the School of Optical and Electronic Information at Huazhong University of Science and Technology. “Not compared to other techniques used in a health care setting. So we wanted to see if we could bring a bit of a boost to that sensitivity and thus improve its accuracy.”

There are two types of electrochemical glucose sensors: enzyme-based sensors and non-enzyme-based sensors. Glucose oxidase (GOx), an enzyme that accelerates (catalyzes) oxidation-reduction chemical reactions, is frequently utilized to oxidize glucose on the surface of the CGM sensor electrode for enzyme-based glucose electrochemical sensors.

It also has decent sensitivity, but not excellent sensitivity. Not compared to other techniques used in a health care setting. So we wanted to see if we could bring a bit of a boost to that sensitivity and thus improve its accuracy.

Huan Liu

The electrode draws electrons from the glucose, oxidizing them, and creating an electric current that changes with the glucose concentration. Due to its strong selectivity for glucose (ability to select only for glucose and not other molecules), high stability, and high activity over a wide range of pH levels, GOx is frequently employed for this purpose.

However, GOx is quickly exfoliated (stripped of some of its layers) when it is mixed directly with the bare electrode surface, and both its biological activity and stability may be impacted. The sensitivity of the sensor is also significantly influenced by the effectiveness of electron transmission between the GOx and the electrode surface.

Numerous attempts have been made thus far to improve the direct electron transfer between the electroactive centers (sites of electron activity) and the electrode surface by making the GOx enzyme more securely adhered to the electrode. One noteworthy endeavor uses electrodes with structures created at the nanoscale to have electrodes with greater surface areas and high electrocatalytic activity.

Unfortunately, these nanostructures increase the complexity of fabricating such electrochemical biosensors. Their construction also relies on the synthetic polymer Nafion as a scaffold, which creates a barrier for the charge transfer across the interface between the sensor and the fluid being tested.

The researchers have therefore gone in a completely different direction. By altering the electrode with colloidal quantum dots (CQDs), the researchers hoped to increase the performance of glucose sensing.

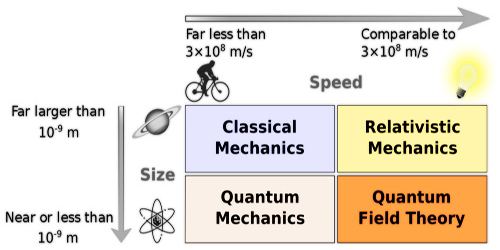

CQDs are “zero”-dimensional semiconductor nanoparticles. (They are not actually zero dimensions, but rather just extremely tiny diameters typically ranging from 2 to 20 nm). These possess an abundance of active sites locations where chemical reactions can occur and bind very stably to biological protein molecules.

And even better, the charge transfer at the CQD-protein interface can be controlled by the application of an external electric field since CQDs experience quantum effects including quantum tunneling due to their extremely small size. Additionally, a variety of various rigid and flexible substrate materials are compatible with CQDs, making it simpler to manufacture them.

The scientists added gold nanospheres (AuNSs) to the sensor electrode’s design to enhance this result. These are incredibly tiny, spherical nanoparticles, with sizes between 10 and 200 nm. They are being used in biosensing applications more frequently as a result of their distinctive physical and chemical characteristics.

In instance, AuNSs lessen the insulating effect of the protein shell for direct electron transfer when used as a component in enzymatic electrochemical biosensors, allowing protein enzymes to maintain their biological activity following adhesion to surfaces. This significantly boosts the signal amplitude of the electrochemical biosensors in a CGM.

The researchers built a proof-of-concept CGM using the AuNSs-modified electrode and lead sulfide-based CQDs. They discovered that, as anticipated, the addition of the AuNSs specifically considerably increased the current signal picked up by the electrochemical sensor.

Together, these modifications demonstrated significant promise for detecting glucose in various samples like blood, sweat, and other body fluids. They also produced an electrochemical biosensor quickly (in less than 30 seconds), with the sort of ultra-high sensitivity the research team was looking for.

The researchers now aim to take their proof-of-concept CGM and make it manufacturable at commercial scale.