Main objective of this report is to analysis Marketing practices of commercially available Poultry feeds in Bangladesh, here focus on United Feeds Limited (UFL). In this report, a special attention is kept to highlight the existing input procurement and output distribution system and identity the problems regarding this industry. Finally find out the problem of distributor handling in United Feeds Limited and give some Guidelines to the policy maker to improve the distributor handling, marketing practices.

Introduction

Generally the term ‘livestock’ is used to designate those domesticated animals such as cattle, horses, pigs, poultry, sheep etc. In the Agricultural Act 1947, the term ‘livestock’ was defined as ‘any creature kept for the production of food, wool, skins or fur, or for the purpose of its use in the farming of the land’ (Somani, 1989, p. 308).

Livestock rising or in other words ‘Animal Husbandry’ is as old as civilization itself. Common farm animals were domesticated before the beginning of written history. Paleolithic man hunted animals for food and his successor, the Neolithic man, tamed and confined them. It was the Neolithic or the New Stone Age men that first practiced agriculture, which included the raising of domestic animals. Since then livestock becomes a part of human civilization (Mahanta, 1987, p.2).

Livestock in Bangladesh

Present status and contribution

Livestock contributes a vital part in agricultural resource in Bangladesh. The total livestock wealth of Bangladesh is estimated at about 23.40, 0.85, 1.16, 33.50 and 13.00 million heads of cattle, buffaloes, sheep, goats, chicken and duck respectively (FAO, 1998, pp. 187, 190 and 193).

Probably the most important and significant role played by the livestock sector is to produce food for human consumption. Every man needs to take protein in his diet. Meat, milk and egg produced by livestock are good sources of animal protein.

Livestock sector also produces another valuable asset i.e. hides and skins. This sector provides annually 72 thousand tonnes of hides and skins (FAO, 1998). Hides and skins, leather and leather products are considered as one of the leading export items of Bangladesh and earn a mentionable amount of foreign exchange in every year. Livestock sector is also a highly viable sector for generating income and employment for the landlessness, unemployed youths, destitute women and thereby reducing poverty level.

Livestock farm in Bangladesh

From the time immemorial, livestock like cattle, goats, poultry etc. are being raised by the farmers. Most of these raisings are traditional in methods and subsistent in nature and, therefore, productivity is very low. To increase the productively as well as profitability in livestock rising, the Government of Bangladesh (GOB) have taken some initiatives in the recent past.

The 1980s, the GOB with the assistance of some donor-assisted projects began to address the needs of cattle farmers and undertook development programmes for the dairy sector. The government initiative has encouraged many farmers in the 1980s and 90s to start commercial dairy farming. In order to patronize this sector the government also introduced a subsidy programme for the establishment of mini—dairy farms and offered liberal credit. The commercial poultry farming was started in the 1980s and thereafter, expanded as a potential agribusiness sector. The Small Farmers Livestock Development Project (SLDP) was started in July 1993 by the Department of Livestock Services (DLS), in collaboration with three national NGOs, namely, BRAC, PROSHIKA and Swanirvar Bangladesh. So far, the project has concentrated mainly on poultry development (CPD, 1997, p, 259)

Due to the patronization from the government, people from different classes became interested in commercial dairy and poultry farming. The number of dairy arid poultry farms in the country gradually started to increase since the later half of the l980s. Now-a-days poultry farming on small scale is a popular farm activity in urban and semi- urban areas in Bangladesh. At present there are about 1, 21,079 dairy and poultry farms and 31,022 sheep and goat farms in the country which are maintained by the private entrepreneurs.

Feed Production and Feed Shortage in Bangladesh

Any material eaten by an animal as a part of its daily ration can be defined as feed (Somani, 1989, p.198). In other words, feed is any edible material which is capable of being digested and utilized by livestock. Feed can he categorized in two broad categories – roughage and concentrates. Feed in roughage category is bulky, fibrous and relatively low in energy. Examples include straw, pasture, silage and forage. Concentrates, as the name suggest, have more concentrated source of energy or protein with less fiber content. Corn, barley, wheat, soybean, bran, molasses are all included in this category. In a traditional and non-commercial condition, people usually raise their cattle mainly on roughage. Though it is economical for an indigenous low-productive animal, but in case of a high- productive animal in commercial farms, it is essential to add sufficient concentrates in its feed ration to maintain the desired level of productivity. In case of poultry, different types of concentrates as well as vitamin and mineral premixes are used intensively as feed.

There is acute shortage of feed in Bangladesh. Major constraints to the development of livestock sector in Bangladesh are identified and stated by many scientists and specialists. Among them, the most common and important constraints is shortage of feed resources. There is a general agreement that low livestock production in Bangladesh is mainly due to lack of feed staff. This situation of feed short is getting worse day-by-day.

In the. Financial year 1994-95, the Government of Bangladesh has taken some steps to meet the increasing deficit of livestock feed. In this regard, the following steps hare been taken –

- Withdrawal of tax on imported feed and feed ingredients.

- Restriction on export of rice bran, rice polish, wheat bran and molasses.

- Taking initiatives to enhance fodder cultivation in fellow lands.

- Conducting research in order to use different non-conventional feed.

- Arranging training programmes on feed processing and preservation.

- Taking initiatives to develop private entrepreneurship in production and marketing of balance feed.

- Taking initiatives to cultivate maize and soybean.

- Establishing seed / cutting nursery at upazila level to promote fodder cultivation in private sector (p. 6).

Though, due to the government’s initiatives, supply situation of feed has improved slightly, but still supply is very much inadequate in relation to high increasing demand.

Feed Mill as an Agribusiness Enterprise

The term ‘agribusiness’ was introduced by John Davis and Ray Goldberg during the mid 1950s. Agribusiness is a name given to the farm inputs, farm, and associated consumer products’ business and their study as an economic and business system (Walter, 1992, p.1) Agribusiness includes all the vital activities performed both on and off the farm that contribute to the food and fiber system’s overall success. This three-part system is made up of (i) the agricultural input sector, (ii) the production sector, and (iii) the processing-manufacturing sector (Beierlein and Woolverton, 1991, p.6). On the other land, an agribusiness product is a product that has significant agricultural origins or is used in agricultural production (Branson and Norvell, 1983, p. 323).

Whereas, ‘Feed mills” are those industrial units where feeds are formulated and manufactured for different productive purposes. It consists of different plants, e.g. receiving of feed ingredients, storage, and mixing, blending, grinding, pelleting, packaging, quality control etc. Feeds are formulated to get maximum nutrient concentration, obtainable at reasonable price for optimum growth, production and efficiency of feed utilization.

The raw materials, those are used as inputs in feed mill, are mainly agricultural products and by-products. After processing these inputs, feed mills produce feeds as their output. This output is used by the non-crop agricultural sector (e.g. Livestock, Fisheries etc.) and considered as the most important input. That is; in one hand feed mills are processing agricultural products and by-products and in other hand producing another agricultural input. So conceptually it is clear that feed mill is an important and significant agribusiness sector. in fact, feed mills act as a linkage between feed ingredients producers and livestock farmers and play a significant role in the over all development of agriculture.

Feed Mills in Bangladesh

Feed mill industry as an agribusiness enterprise is comparatively new in Bangladesh. There was no special feed producer i.e. feed mill in the country before the decade of eighty. Total feed business, especially, the business of concentrates was controlled by some feed traders who had neither any scientific knowledge on feed formulation nor any mechanical devices to prepare balanced feed. Mainly they collected different agricultural products and by-products from different parts of the country and sold those items as feed to the livestock farmers. Occasionally, they used to mix up those items together by manual methods without maintaining balance proportion. In fact, they generally added only place utility and sometimes form utility in a small degree.

The Government of Bangladesh is the pioneer in establishing feed mill in the cctntry. L order to supply feed to the public sector farms, the Government established feed mills at ‘Regional Poultry Farm’ in Chittagong city and ‘District Pou1t Farms’ at Jessore and Rangpur district in the early f980 Two large feed mills in private sector, namely, Monnu Garimexpexpal and Solvent, were also set up in the early 1980s, but they were closed down before 1990. In 1987 ‘Saudi Bangla Fish Feed Ltd.’ was established at Bha upazila in Mymensingh district with the assistance from Saudi-Bangladesh Industrial and Agricultural Investment Company Ltd. (SABINCO). In fact, it was the first well organized private sector feed mill in the country. At present there are 23 feed mills using mechanical devices for mixing and or pelleting the feed.

Importance of Feed Mill

Feed mill plays an important role in the development of livestock sector and thereby it contributes a lot in the national economy of Bangladesh. (As feed is the key input having strong influence on the productivity of livestock, balanced feed with superior quality is essential for the successful farm operation) Feed intake accounts for approximately 65-70 per cent of the total cost of a farm p. 257) the most significant constraint in the development of livestock sector is the acute shortage of balanced feed, which has been discussed earlier. In recent past, many small scale dairy and poultry farms were established in the country, but 20 to 25 per cent of dairy farms and 25 to 30 per f poultry farms dropped out in their out in their stage (CPU, 1997, p 257). Among the major causes of this drop out, one was the unavailability of feed.’

Though there is a scope to meet the shortage of feed ingredients through import, the farmers have not adequate technical know-how and mechanical devices to prepare balanced feed for their livestock at farm 1evel. are some micro ingredients like vitamins, minerals, enzymes etc. which are needed to add in a very small proportion, say as in 1:10,000 ratio, in feed formulation, hut have a great impact on the productivity. It is not possible to mix these micro ingredients homogeneously and maintain the feed quality properly without using automatic machine. In feed formulation, highly sophisticated method of calculation and different chemical testing is necessary which require a huge investment and no doubt it is out of reach of the farmer. The feed mills are specialized in such kind of job. They have adequate capital, modern mixing plants, and well equipped laboratories, technical and skilled personnel to perform these works. Moreover, feed mills not only use modem hardware and specialized people but also import technology related to production, grain handling, storage, feed formulation etc. Thus, by ensuring the supply of quality feed for livestock sector, the feed mill industry is enhancing the whole economy significantly through its forward linkage effect.

The feed mill industry improves the efficiency and digestibility of feed through scientific formulation and processing and helps efficient use of scarce feed resources

This industry also generates a number of employments in the processing plants and involves a number of people in feed distribution channels.

Rapid urbanization, population growth, increased income etc. would lead to higher demand for livestock and livestock products in the future, the capability to meet that demand will greatly depend on the ability to feed those livestock in an efficient and balanced way, which can only be done through well equipped feed mills. This increases the importance of the industry day by day. Realizing the in1portance of this industry, the GOB is trying to make involved more private entrepreneurs here. To develop this industry the GOB has undertaken ‘Feed and Fodder Development Programme’ in the Fifth Five Year Plan. Under this programme feed mills will be established in the private sector at important places of the country and the government will provide support services in the form of credit and technologies (GOB, 1998, p. 255).

Rationale of the Study

In recent years the feed mill industry is emerging as a prospective agribusiness sector. Its importance in national economy is increasing day by day. But this industry is still very much unorganized. As the time progresses, the demand for complete feed increases rapidly. According to the available information, the country needs about 3.6 lakh tonnes of feed annuals for the poultry in private sector only. If the poultry in public and NGO sector are include in calculation, the figure will not be below 5 lakh tonnes per year. If the current growth rate in poultry sector can be maintained, the annual demand for feed will be about 10 lalch tonnes within the year 2005. The available information also supports that all feed mills produced collectively only about 15 per cent of the animal feed demand in the year 1999 (2ooo, p. 6). So there is a large untapped market of feed and it seems that the feed mill industry offers the greatest opportunity to the agribusiness entrepreneurs and investors for profitable investment. But due to unorganized nature of the sector, there is a huge information gap. The present study is an attempt to fill this gap.

To have a clear understanding about such a potential industry, the present study is a modest attempt to examine the structure, conduct and performance of feed mills in Bangladesh. In this study, a special attention is kept to highlight the existing input procurement and output distribution system and identity the problems regarding this industry. So, this study may be useful both at micro and macro levels.

The information provided by the study may be helpful to the existing and potential entrepreneurs and market participants to improve their performance and take decisions. This study may help the policy makers in national level and relevant government and NUG agencies in the formulation of policies aimed at the development of livestock sector. The prospective researchers can also find the study useful in conducting further research.

Though foci processing is an important agribusiness sector of the country, neither economic nor market oriented study has so far been conducted in this sector. On these grounds this study is important and justified one and may play a vital role i;i the development of livestock sector in the country.

Objective of the Study

The growth potential of the poultry feed industry is very good in Bangladesh. Inspite of the existence of the high growth potential, to be one of the largest industries in Bangladesh, a lot of strategic initiatives are yet to be taken for the industry. The broad objectives of this report are to analyze the current situation of the industry in terms of strategic position and moves. This broad objective can be subdivided into specific ones, which would be coverd in this report, are as follows:

A) A generic process flow for the enterprise would be derived through the identification of different actors of the enterprise, their operation, linkages and interdependencies.

B) To find out the problem of distributor handling in United Feeds Ltd.

C) To give some Guidelines to the policy maker to improve the distributor handling, marketing practices in United feeds LTD.

Methodology of the Study

As this study only intends to cover the present situation regarding the knowledge and practices within the Fisheries industry as a whole and key players of industry surrounding issues like external environment, internal environment, key generic strategies, driving forces etc., the research has been a cross-sectional one which is exploratory in nature.

The research encompassed qualitative study both at primary and secondary level of the research. In depth interviews I conducted on some of the Fish feed consultants to get a broader picture of the industry.

The major source for the Secondary Study has been internet, text books, business Journals, and brochures of enterprises within the industry.

Theoretical of the Discussion

Back Ground of the Company:

Started in 1976, entrepreneur by Mr. Mostafa Kamal, MEGHNA GROUP OF INDUSTRIES is one of the largest and very fast growing industrial conglomerates in Bangladesh. Meghna Group of Industries produces most essential food and beverage for human and animal consumption, construction material, packing materials and electric power in its plants located at Meghna Ghat, Sonargaon, Narayangonj. The group has about 6000 permanent employees and around 2000 casual labour force. Its annual turnover is approximately TK.2,000.00 crores (around US$ 300.00 Millions) and thus contributed much to the industrialization and development of the socio-economic condition of the country in terms of reducing unemployment, saving valuable foreign currency and reducing import dependencies and earning foreign currencies through exports of its products . For the uncompromising product quality and strong management policy most of the industrial units of the Meghna Group has been awarded ISO9001; 2000 certification. The group has been awarded the Nawab Sir Salimullah Gold Medal presented by the Honorable President of the People’s Republic of Bangladesh for its magnificent performance in the industrialization of the country and also awarded the International Star Award for Quality (ISAQ) in Gold Category by BID (Business Initiative Directions) in Geneva on October 10, 2005 for commitment.

Meghna Group of Industries is entirely a customer focused company and has set a new standard since its emergence. It promises to deliver: Purity Quality Safety Freshness to its consumers at all times

Its brand name, FRESH under which most of its products are available in the market, denotes the promises rightly to the consumers. The FRESH brand assures to deliver with superior taste enhanced health and wellness benefits.

MGI brings few products in the name of Super FRESH which gives more of the direct understanding of the refining process. MGI has few other brands in its portfolio – Pure, Super Pure and Golap. The Products & Services of MGI are

FRESH brand :

- Full Cream Milk Powder

- Sugar

- Atta-Maida-Suzi

- Tea

- Spices

- Salt

- Mustard Oil

- Cement

- Poultry & Fish Feed

Super FRESH brand:

- Natural Drinking Water

- Soybean Oil

Others:

- SUPER PURE Vegetable Oil

- Paper

- Woven PP Bags

- Power Plant

- Dockyard

- Steel Drums

- Real Estate

- Chemical

- Condensed Milk

- Soymeal & Rapeseed Cake

Services:

- CNG Refueling & Conversion

- Printing & Packaging

- Shipping

- General Insurance

- Stock Securities

- Logistic Support

OPERATION IN BANGLADESH:

United Feeds Limited has divided the whole Bangladesh into 11 regions. There are four sales depots into the specified region. No. of Feed Mills two. Production Capacity in Commercial Feed Mill Around 3,000ton/month & 7 ton/ hour.

MARKET PROFILE:

- Total Investment: Tk 100 million.

- Fixed Asset: Tk 400 million.

- Market Growth Rate: 10%.

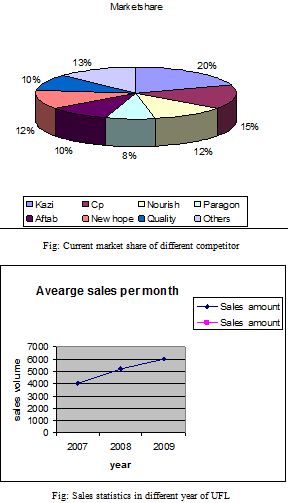

- Market share: 20 % (2010) in Poultry feed sector. .

- Market Demand: 250000 tones Poultry feed in a month.

COMPANY’S MISSION, VISION, STRATEGY & DICISION MAKING PROCESS:

Mission

The mission of the UFL is “To Produce best quality Poultry feed of the country, compatible with International standards”. The future of Poultry industry in Bangladesh is promising and dynamic. Foreign companies are setting up and expanding operation here. Competition is becoming harder. Only the fittest will survive. Procedures must focus on quality and productivity. UFL has prepared for the future by building world class facilities and mastering new technologies.

- UFL is committed to the well-being, proper handling and human slaughter of all the fry which we manage internally, or produce for sale to the poultry industry worldwide.

- This has been a long-standing commitment, and will continue to be a focal point for our future.

- We pledge our diligence in leading the industry not only in the pursuit of new and improved genetics and technology, but also to lead in enhancing animal well-being.

- This is not only the right thing to do, but it is an important obligation we owe to our customers.

Vision

The vision of the UFL is “To be one of the best managed commercial organizations in Bangladesh in terms of quality, technology, innovation, operational excellence and growth. To produce poultry feed the highest international standards”.

- UFL are devoted to build a regulated, environment friendly and world class leading agribusiness enterprise.

- UFL believe, as a leading agribusiness enterprise in Bangladesh will become a major player in the world.

- UFL are committed to create distinctive values for all stakeholders including employees, suppliers, clients, debt holders, shareholders and communities.

- UFL share the opportunities both in Bangladesh growing economy and society and seek to achieve profitable and sustainable growth.

UFL strengthen our market position and develop momentum by building solid domestic and international partnerships.

UFL’s Values

At UFL, we adhere to our basic values: to be positive, normative and innovative, which guide us to believe in our culture.

In this cultural system, UFL is like a family where we are treated with warm and broad hearts; a school where we are devoted to studying and promoting our skills; and an army where we strictly follow the disciplines to ensure the healthy order of business management.

UFL’s Targets

We create and deliver solutions to help customers meet their goals. We provide value through products, services and innovation. We measure success by consistent growth, commitment to our customers, society, a rewarding employee experience and financial benefits to our shareholders.

Corporate Strategies

- Quality and Customer acceptance– Achieve business vision through quality and customer acceptance by providing quality full day-old chicks.

- Good manufacturing practice- Strictly maintained GMP (Good Manufacturing practice).

- Compliance-With regulatory requirements, corporate quality requirements and other applicable standards.

- Added Value- Through continuous improvements and error-prevention to benefit customers and company.

- Dedicated Human Resources- Develop a pool, of dedicated human resources through regular training.

Quality Statement

Quality is at the heart of everything we do- from the discovery of the module, through product development, manufacture, supply and sale- and is vital to all the service that supports our business performance.

Commitment

- To produce high quality product.

- Delivering competitive business advantage.

Responsibility

- The health and safety of employees, contractors, visitors.

- The protection of the environment and our communities.

- Compliance with laws and UFL standards.

UFL Functional Departments

UFL comprises of seven major departments. They are as follows:

- Sales & Marketing

- Finance

- Human Resource

- Technical

- Production

- Customer Care

Each department at UFL operates in different aspects but they are inter-related and complement each other. The main functions of these departments are shown below:

Marketing

- Designing and implementing sales strategies.

- Controlling and updating distribution network.

- Designing and carrying out promotional programs.

- Providing marketing information services.

- Carrying out different awareness programs.

- Keeping records of data regarding marketing activities.

- Building up public communication network.

- Conducting marketing surveys as needed.

Finance

- Controlling the accounts

- Completing the annual budgets.

- Allocating all kinds of payments to the staffs and managers.

- Looking after all the revenues and expenses.

- Conducting internal audits.

- Keeping records through IT.

- Facilitating local production cost.

Human Resources

- Recruiting and training the best pool of employees needed for the company.

- Managing smooth workflow in the organization.

- Managing demands of the labors in the factory.

- Allocating annual holidays.

- Arranging for employees motivational programs.

- Looking after the wage structure and waivers.

Technical

- Producing precise amounts of products as per the year plan.

- Ensuring total quality management.

- Following good manufacturing practice.

- Implementing raw material management.

- Procuring and allocating assets efficiently.

- Prioritizing best possible observations over the produced goods.

Production

- High Quality

- Maximum volume of production

- Follow TQM in the production

Consumer Care

- Making sales planning.

- Arrange agent conference.

- Spot meeting.

- Problem solution of agents or farmer.

- Market Survey.

- Arrange training program.

Administration

- Create good officer environment

- Store the all information.

- Evaluation of departmental performance.

- Generate plan.

- Organize official meeting.

Products and services

- UFL has been engaged in agribusiness for 11 years. We are one of the largest poultry feed producer in Bangladesh with annual production capacity of 60 thousand tonnes.

- UFL is an important platform for promoting the development of Bangladesh

agribusiness industry.

- UFL is one of the earliest and most successful private investors in the financial service. We also hold the trust companies, insurance companies and equity of listed companies

Types of UFL product:

- Broiler feed

- Layer feed.

- Cattle feed.

Nature of United feeds Ltd

- Broiler feed: Especially for broiler. It is a very high quality feed .It is three types.

- Broiler starter(0-14 days):

-small bird, needs less energy to maintain body temperature.

-Grows quickly, needs more protein, vitamins, and minerals.

- Broiler grower(15-22 days):

-Medium size bird

-still growing quite fast, so needs some protein

-Already has fairly high body weight, so needs some energy

- Broiler finisher(22-30 days):

-Big bird, needs a lot of energy

-Grows slowly, needs less protein etc.

Nature of UFL layer feed:

It also a high quality feed. It contains moisture, crude protein, crude ash, crude fiber, fat, calcium, phosphorus, salt, methionine. It has five classes:

- Layer pre-starter feed: 0-10 week

- Layer starter : 10-17 week

- Layer grower : 17-18 week

- Layer layer : 18 week –upto week

- Layer layer : 18 week –upto week

Character of layer feed:

- Apply advanced production technology, decrease ant nutritional factors, improve absorption-utilization rate of nutrients.

- Add probiotics or antibacterial agent, anticoccidial agents which can improve the resistance power against disease and survival rate of layer, specially reduce sudden death by coccidiosis.

- Layer group has high uniformity.

- Layer has higher-egg production rate and a longer laying period and high feed conversion rate. In case of good breeding condition and disease prevention in all phase feed conversion rate is about 2:1(feed: egg).

Results and discussion

Overview of UFL

Originated from Mr. Mostafa Kamal family business commenced in 1982, In addition to the operation in agribusiness, we have also developed a diversified investment portfolio in chemical industry, financial institutions, real estate and other utilities. As in its 19th year, UFl has a clear industrial pattern within which the four major industrial clusters are effectively operated: agribusiness and food, chemical industry and resources, real estate and infrastructure, finance and investment, all of which are like four wheels driven the business move forward

With annual sales of around $3.5 billion, Ufl operates agribusiness and over 20000 employees. As one of the largest agribusiness enterprises and the leading agribusiness operator in bangladesh, Ufl is devoted to building a long-term service of agribusiness, creating a better life for our consumers, providing a platform both for our employees and partners.

UFl has been engaged in agribusiness for 11 years. We are the largest feed producer in Bangladesh with annual production capacity of 72 thousand tonnes.

Products and services

UFL is one of the earliest and most successful private investors in the financial service industry. We also hold the Media companies, insurance companies .

Objectives of UFL

UFL strongly believes that international partnership will help to upgrade its corporate governance and add to its competitive advantages. UFl can help international investors by its deep understanding on indian market and society, extensive market network, cost-effective management and working force, sensibility to the changes in indian market and regulatory environment.

SWOT ANALYSIS OF UNITED FEEDS LIMITED

SWOT analysis is a tool for auditing an organization and its environment. It is the first stage of planning and helps marketers to focus on key issues. SWOT stands for strengths, weaknesses, opportunities, and threats. Strengths and weaknesses are internal factors. Opportunities and threats are external factors.

Strengths of United Feeds Limited (UFL)

- UFL unique strength is his product quality. At present their quality of product is best in Bangladesh. Customer is getting expected result of ufl feed. Ufl are maintaining their feed quality same . For that reason their sales volume has been increasing day by day.

- UFL marketing department is highly experienced. All the personnel of marketing department are recruited of the graduate of Bangladesh Agricultural University. They are very skilled in technical side as well as sales & marketing.

- UFL product delivery system is very smooth. Customer can easily get their goods without any hazard. Ufl feed mill production capacity is 20 metric ton per hour which helps their delivery system.

- UFL believes good relationship with customer. They keep the good relationship with customer all the time. Customers are also satisfied.

Weakness of United Feeds Limited

In Bangladesh poultry industry is very much competitive. Every company tries to strength their position. Kazi farms, CP, Nourish, Aftab, ACI-GODREJ, Quality feed are the major competitor of Ufl. Customer needs chicks & feed. At first they need chick .Then feed. Every company above mentioned both have chicks & feed. That’s why this company’s sales volume remains steady. But ufl sales volume does not remain same. When chick’s crisis is come then ufl sales volume is declined Because ufl don’t have chicks. This is ufl weakness.

Opportunities of United Feeds limited

- There is a big market of poultry feed in Bangladesh. Day by day the market size is increasing .There are 50 thousand tons poultry & fish feed market in Bangladesh. UFL has a great opportunity to capture maximum market share indeed. For that reason they have to setup hatchery for chicks. After bringing chicks UFL Sales volume must be increased & will be able to gain maximum market share.

- There is also a big emerging market of chicks. Kazi farm, CP, Paragon are dominating the market. Around 55 lac DOC (Day Old Chicks) is needed every week in Bangladesh poultry market.UFl can easily enter this chicks market if they bring DOC& able to do enormous profit

Threat of UFL

- There is a big threat for UFL is Bird Flu. When this bird flu is breakout the market face great difficulties. Broiler & Egg price is declined. Farmer doesn’t want to take chicks. Finally UFL sales affected badly. Other competitor company also faces same kind of problem.

- Competitor Company is trying to increase their feed quality & also strengthen their chick’s side. It is also big threat for UFL if they don’t setup hatchery for chick’s production.

About United Feeds Ltd:

UFL invests 100,000,000 TK. And establishes a modern feed mill with yearly output of 60,000 Tons. The products of poultry feed and fish feed are fit for the breeding environment in Bangladesh. Covering an area of 40 bigha, our company is located in Meghna ghat sonarghaon with convenient transportation. Having received great supports from Bangladesh government and all circles of the society, we will do utmost to seek a development path with the diligent opportunities to our dealers and customers. The establishment of UFl Mill Bangladesh Ltd will bring huge improvement for the poultry and aqua feeding business in Bangladesh.

Advanced Production equipments and Nutrition technique:

Our company fetches in two sets of UMT600 floor-style feed equipments which are the most modern all over the world including different diameter cylinder conditioner, high-powered hammer mill, double-shaft paddle mixer, liquid adding equipment. Full computer controlled system, special fish feed production line to produce high quality poultry, fish, shrimp and animal feed. United Feeds Ltd is formulated by Feeds Research Center of Meghna Group is consideration of special conditions in Bangladesh like local climate, available raw materials, breeding practice, etc. Which can help poultry and fish improvement, disease resistant, get the best nutrition-absorption, improve growth and be able to endure high temperature and long distance transportation? Our product covers the whole Bangladesh benefit millions of farmers.

About marketing department of United Feeds Ltd

- Convenient marketing network and consummate technical service:

The high-effect marketing team of our company is shutting back and forth in each market place. We provide the convenient and effectual business liaison for extensive qualified customers to sell or use United Feeds ltd in Bangladesh, and we also build a fine cooperative relationship between customer and us.

- About Human re Resource of Marketing Department:

United Feeds ltd marketing department has very skilled and high efficient human resources. Including 30 excellent employees out of which is maximum Animal Husbandry graduate, Fisheries graduate, Veterinaries, Agriculture graduate from Agricultural University. We have a good grasp of advanced technology and professional research group with loyalty, high efficiency and honesty.

About Management of marketing department:

Management of marketing department is very experienced and reserves vast knowledge about Sales Marketing. One marketing manager is the main person in this Marketing department. He is highly experienced in sales and marketing and has lot experience acquired from other local company. One Asst Manager Sales always supporting him to executes Marketing Department works. With the assistance of Asst manager and two offices executive Marketing Manager conduct marketing department of United Feeds ltd Bangladesh Ltd.

Aim of Marketing Department Management:

- To provide best quality product to customer.

- Always try to give better service to our valuable customer for gain customer trust and satisfaction.

- Share success together with the customer.

- Develop together with the stuff.

- Advance together with the society.

- To establish United Feed Mill Bangladesh Ltd a trustworthy and one of the best company in poultry industry in Bangladesh.

Marketing Department services of United feeds Ltd :

- Let our company resemble a family, a school and a troop. Rely on tremendous strength of our group and company and credit standing to our extensive dealers and farmers getting rich and developing.

- United Feeds ltd Bangladesh Ltd technical services department is composed of professional staff of animal husbandry and veterinary to offer the breeding technique and training for extensive farmers in whole day.

- Arrange a scientific seminar on Poultry Management participants of some farmers where they can gather knowledge about best poultry management.

- Ensure 7 days in week product delivery service without facing any damarage.

- Training is given to the marketing executive in order to increase their ability to sell and strengthen their product knowledge.

- A dealers conference is arranged every year where participate all over Bangladesh dealer and rewarded them in order to encourage them about more selling.

Future plan of Marketing Department of United Feeds Ltd:

- To establish another Feed Mill in Bangladesh to expand their current business all over in Bangladesh.

- To set up hatchery in order to begin DOC means chicks business in Bangladesh.

- Meat processing plant and broiler intrigation will be started very soon.

- To become number one Feed and chicks producing company in Bangladesh.

The major companies that dominate poultry industry:

The poultry companies are mainly classified into three groups:

1) Feed companies, 2) Chicks (Broiler & Layer) companies 3) poultry medicine companies.

Feed companies: There are more than 50 commercial feed companies who dominate the industry. Beside these there is some small local feed mill that has very small volume of production to meet self and local poultry farms.

The major and giant feed companies are:

a) Quality feed mill

b) Nourish poultry & hatchery

c) Kazi farms ltd

d) CP Bangladesh ltd

e) New hope feed mill Bd. ltd

f) Paragon poultry ltd

g) Lion agro complex

h) Aftab feed ltd.

Most of the chicks companies have feed mils. These companies follow a unique marketing policy to sell chicks; that is- they sell the Day over chicks to those dealers who buy their feed. As for example Kazi chicks dealer are bound to take Kazi feed.

Findings of the study

Introduction:

Study of the problems related to an industry is necessary in order to acquire a clear idea about that industry. Generally the reason and causes those obstruct or hamper the achievement of objectives are denominated as problems. Whereas, suggestion are indication of some measure to overcome these problems. The main purpose of this chapter is to identify some major problems relating to the industry, those have strong influence in feed production as well as feed marketing and suggest some measures to overcome these problems. The discussion on the problems relating to the feed mills industry is done under three major heads:

- Problems faced by the poultry feed mills.

- Problems faced by the poultry feed traders

- Problems faced by the poultry feed using farms.

Problem faced by the Poultry feed Mills

In the present study, the Poultry feed mills in Bangladesh were found to face a number of crucial problems. Among which seasonality in feed demand, uncertainty in raw materials availability, lack of alternative grains, variation in price and quality off raw materials, absences of departmental quality control measures, faulty techniques of grain harvest and strong, high rate of tax and other charges, lack of database and other problems like political hazard and power failure etc. were treated as major problems by the responding feed mills. the responses of the poultry feed mills presented in table 6.2

A brief discussion on those problems is also presented in the succeeding paragraph.

Table : Problems faced by the feed mills

| Problems |

|

Seasonality of feed demand

All of the firms mentioned seasonality of feed demand as one of their major problem. The demand for feed was not equal in all the months of year. It was noticed that, the feed mills were using twice or more than twice of their plant capacity in the peak months, whereas, in the lean months they were found to use one or third or less of the plant capacity. The feed mills claimed that due to this seasonality they were not able to utilize their plant capacity fully throughout the whole year.

Uncertainty of raw materials’ availability

In the study, feed mills were noticed to face crucial problem arises from uncertainty of raw materials’ availability. All of the firms under the industry mentioned it as one of their major problems. In Bangladesh, maximum raw materials of feed industry were imported from abroad. The feed mills were found almost fully dependent on the imports of raw materials. Supply and availability of these raw materials in the local market were not smooth throughout the year. These raw materials were found very much scarce whenever any complexity arose in import and shipment and thereby production of the feed mills was hampered greatly.

Lack of alternative grains

The most commonly used grain in feed preparation was maize. Locally produced maize could fulfill only a small portion of the total requirement. Sometimes wheat was also found to be used as an alternative of maize. But it was also a scarce grain having many alternative uses. No other alternative of maize and wheat was available in the local market. This scarcity of alternative grains was mentioned as an important problem by about 87 per cent of the responding firms of the industry.

Variation in price and quality of raw materials

Wider variation in price and quality of raw materials used in feed preparation was mentioned as a major problem by about 78 per cent of feed mills of the industry. The price and quality of processed feed greatly depends on the price and quality of the raw materials used. Due to variation in raw materials’ price and quality, the feed mills were not able to maintain the same price and quality of processed feed in every batch. Thus a way the feed mills were found to face serious problem in building reputation and goodwill of the firm and creating brand loyalty of the customer.

High rate of tax and other charges

About 74 per cent of feed mills mentioned that high rate of income tax and other charges like electricity, gas, fuel etc. were another important problem of the industry. Though the feed mills industry was declared a tax-holiday industry, but this tax exemption will be withdrawn in the year 2005. The respondents opined that it would create a serious problem for the whole industry. They also expressed that the existing high rate of income tax also discouraged the existing entrepreneurs and potential entrepreneurs for grater investment. In spite of its linkage with one important agricultural sub-sector, the industry did not get advantage of lower charges for electricity, gas, fuel etc. like other agricultural enterprises. It was found that normal commercial rate was employed on the industry for electricity, gas, fuel etc.: which was higher than the agricultural rate of charging.

Lack of database

It is a matter of common understanding that, proper and adequate data is necessary for the development of any sector, in Bangladesh, the previous survey report on livestock sub-sector was published in 1994 and after then no detail survey on this sub-sector was conducted. Moreover, data on livestock sub-sector provided by different organization were confusing and different. About 70 per cent of firms identified it as a problem. They claimed that due to absence of appropriate and adequate data they were facing problem is assessing future demand of feed and setting appropriate production plan.

Faulty techniques of grain harvest and storage

Sixty five per cent of the firms reported that they were facing problems from the existing techniques of grain harvest and storage. The harvest and storage techniques used for grain at farm level and intermediary level were faulty. In order to maintain good quality, the grain should be harvested after fill maturity, dried properly before store and stored in a well-controlled condition. But due to ignorance, farmers and intermediaries often neglected these prerequisites. As a result, grains were noticed to lose their desired quality, which affected the quality of prepared feed very much.

Political hazards

About 61 per cent of the feed mills claimed that they were affected seriously by the political unrest strikes and other political hazards.

Absence of quality control measures

Fifty two per cent of the firms mentioned that they were facing problem due to absence of quality standard or quality control measures of government to evaluate the quality of imported raw materials and processed feeds. For this reason, the importers did not bother about the quality and chemical composition of the raw material and often they were found to import low quality raw material to earn a higher profit.

These feed mills also mentioned that, there was no minimum quality standard or quality control measure of the government agencies for ensuring the quality level of processed feed marketed in Bangladesh. Due to this reason, some dishonest businessmen were using low quality feed ingredients intentionally to reduce their production cost of feed.

Power failures

Twenty six per cent firms mentioned that power Failure hampered their production and thus a way it created problem. It can be mentioned here that, majority of feed mills (74%) had generator facilities and as a result they did not face problem due to power failure.

Problems Faced by the Feed Traders

The feed traders in the sample of the study were found to face some problems. According to the statement of these traders, the main problems were inadequate supply of feed, tendency of purchasing feed on credit, price conscious nature of the feed using farms, price fluctuation of feed, lower profit of the business etc.

Inadequate supply of feed

All sample feed traders mentioned that inadequate feed supply was their main problem. They stated that the supply of feed by the feed mills were inadequate and irregular. In the peak months the supply of feed from the feed mills was found very much inadequate. They also claimed that due to inadequacy of feed supply they were not able to fulfill the customers’ demand and thereby lost their probable profit.

Tendency of purchasing feed on credit

About 83 per cent of the sample feed traders mentioned that another important problem of their business was the tendency of the feed using farms to purchase feed on credit. According to their statement, a large portion of their total sale was generally occurred on credit and they often faced serious problem to recover this money.

Price conscious nature of the Iced using farms

About 77 per cent of the sample feed traders stated that they were facing problem due to the price conscious nature of the feed using farms. They claimed that most of the feed using farms, especially the small and medium scale farms, were price conscious rather than quality conscious in nature. These feed using farms preferred low quality feed and feed ingredients due to the low price.

Price fluctuation of feed

About 67 per cent of the feed traders claimed that they were facing problem due to fluctuating nature of feed price. They stated that because of price fluctuation they were losing the trust of the customer on them and many of their valuable customers. Thus, the price fluctuation of feed curtailed the probable scope of business of the feed traders.

Lower profit of the business

About 63 per cent of the sample feed traders mentioned the lower profit of feed business as a problem. Generally the retail price of feed was fixed by the feed mills and the traders used to follow the price. The retailers generally got only Tk.0.30 to Tk. 0.80 off from the per kg retail price of feed which was about Tk. 14.00 per kg on an average. Along with this, transport and other associated costs were paid by the feed traders themselves. The feed traders expressed that after bearing the transport cost they earned a very small profit, which was not attractive enough in relation to other business.

Problems Faced by the Feed Using Farms in Relation to Feed

The sample feed using farms were found to face some crucial problems. Among these problems, unavailability of feed in the peak season, high price of feed, lack of quality testing facilities, lack of credit facilities, lack of government regulation etc. were mentioned as the main problems. The responses of the sample feed using farms are presented in Table 8.3. A brief discussion on these problems are also stated in the succeeding paragraphs.

High price of feed

All responding farms noted high price of feed as important problem of farming. The farms claimed that the price of prepared feed was high. Due to the high price of feed, their cost of production was also high. But the price they got for their product was comparatively low. As a result, the farms were facing the problem of’ ‘cost—price squeeze’

Unavailability of feed in the peak season

All the responding farms complained that there was unavailability of feed in the peak season. It was found that demand for feed usually increased very much in the winter season. The farms claimed that sometimes they were not able to collect feed in the winter though they were ready to pay a higher price. This unavailability of feed impeded their production very much and thereby created problem for them.

Lack of quality testing facilities

Ninety per cent of the selected feed using farms stated that they were facing problem of lacking of quality testing facilities. They mentioned that they did not have the facility to test the quality of feed at field level. Usually they used to purchase feed on good faith, but they claimed that sometimes the quality of feed was not satisfactory enough.

Lack of easy credit facility

Sixty per cent of farms stated that their capital was inadequate and they often suffered from acute shortage of working capital. According to their opinion short- term credit facility in easy conditions was very much necessary for their production. But such facility was not available to these farm and thereby facing problem.

Lack of government regulation

About 47 per cent of the responding farms expressed their opinion that lack of government regulation and quality standard for feed was another important problem. They argued that due to absence of any government regulation and quality standard, some feed mills were using low quality ingredients for feed preparation. They also claimed that the actual quality of feed often found to vary from the stated quality of feed.

Recommendation of the Study

Suggested Solutions

From the above discussion, it is clear that the feed mills, feed traders and the feed using Farms under the study were facing many problems. To overcome these problems the following solutions were suggested by the respondents:

(i) The Department of Agriculture Extension of the GOB and NGOs should lunch vigorous and comprehensive efforts to increase the production of maize, wheat, soybean, sunflower etc. throughout the country in order to reduce dependency on import.

(ii) The government should take initiatives to import major raw materials directly from abroad through Trading Corporation of Bangladesh (TCB) or other alike agency and supply it to the feed mills on actual cost basis.

(iii) Feed standardization and quality control act of feed should be formulated immediately and placed the activities under regulatory agency.

(iv) The quality level of the imported raw materials should be tested properly. Easy and low cost feed testing facilities should be established at the different poultry zones of Bangladesh.

(vi) Charges for land, electricity, gas, water etc. used by livestock farms and its allied industries like feed mills etc. should be at normal agricultural rate.

(vii) To reduce the information gap in livestock sub-sector, initiatives for a detail survey should be taken immediately. A decision of upgrading the information in every year can also be taken. The variation of information provided by different agencies should be removed through co-ordination.

(viii) To reduce the shortage of working capital of the small and medium poultry farms, a special short-term easy credit programme should be introduced through the institutional sources of credit.

Conclusion

The poultry industry in Bangladesh is very diverse. It comprises broiler chicken, layer chicken, native chicken, and ducks. The production of broiler and layer chicken is characterized by large-scale, intensive, commercial production systems with modern technology and imported hybrids. Native chicken production, on the other hand, is usually a backyard activity undertaken by rural households using minimal inputs. It appears that the Bangladesh chicken meat industry, including broiler and native chicken, stands to benefit from an increase in demand because of the anticipated growth in population and household income. However, it faces a number of challenges. For the commercial broiler sector, its main concern would be the threat from global competition because it is a high-cost producer by world standards. The future of the commercial sector will depend largely on the availability of cheap feed sources and improvements in production and marketing efficiency.

This is an expanding sector needing diversification in technology, production of feeds, medicine and vaccine, skilled manpower and above all wider scale of investment. In this respect poultry deserves to get more attention from policymakers.

In future Bangladeshi poultry industry stands to benefit from increase in demand because of the expected growth in population and income. However, it faces a number of challenges. Among others, the main concern is the increasing global competition. As the policymakers pursue deregulation of the poultry sector, the future of the poultry sector would depend on the availability of cheap imported inputs and improvement in production and marketing efficiency. These will require coordinated efforts from both the private and public sectors.

However, the backyard sector faces serious issues of low productivity and high mortality rates because of the lack of technical know-how and access to key inputs. In developing countries like Bangladesh, the backyard poultry sector represents the basis on which a sustainable, well adapted semi-commercial sub sector could be progressively developed. The key recommendation here is to undertake more research that would identify not only the constraints to subsistence backyard production but also the means for effective extension and technical assistance.

As the world broiler market is highly competitive, with an increasing number of efficient producers fighting for market share. Major broiler exporters such as the United States, Brazil, and Thailand, succeed in the international market by competitive pricing, aggressive marketing, and new product development. Their successes are based on well-managed and coordinated supply chains that meet changing consumer demand and increasing government regulations. To combat the threat of import from big players, the Bangladesh broiler industry requires improving farm productivity by adopting latest technologies and better management practices. In addition, there appears to be a need for the industry to become fully vertically integrated to benefit more from the economies of scale and scope. There is need to adopt the latest technology in poultry raising, particularly in the areas of environmental control and automation in feeding, drinking, and other management practices. Production inefficiency, along with the reliance on high-cost imported inputs has resulted in a higher production cost of live birds. Technical skills need to be considered at both farmer and extension levels. Training is essential for both farmers and extension officers in the following areas: disease control, housing and equipment, feeding, genetic improvement and marketing.

A basic knowledge in specific features of poultry anatomy/physiology is also important to understand the basis of the above topics. Housing and management could be improved through appropriate farmer training, preferably conducted on-farm. Local craftsmen could be trained to manufacture small equipment, like feeders, drinkers, etc.