Introduction:

The Malcolm Baldrige National Quality Award is one of three global quality awards coveted by companies all over the world. While the award is largely US-centric, the basic parameters for selection of companies have been adapted by several organizations across the globe to evaluate quality.

History of the Award:

The Malcolm Baldrige Award, established by the U.S. Congress, was first implemented in 1988 to recognize quality achievement and excellence of U.S. Companies.

The award has been instituted in the memory of Malcolm Baldrige, the famous industrialist and also served as the US secretary of commerce for seven years in the Ronald Reagan administration.

Baldrige’s award-winning managerial excellence contributed to long-term improvement in the US economy, and efficiency and effectiveness in the government. Prior to entering government service, he served as chairman and chief executive officer of Scovill Inc, where he is credited with leading its transformation from a financially troubled brass mill to a highly diversified manufacturer of consumer, housing and industrial goods.

Purpose of the Award:

The Malcolm Baldrige National Quality Award is an annual Award to recognize U.S. companies for business excellence and quality achievement. The purposes of the Award are to promote awareness of quality as an increasingly important element in competitiveness, understanding of the requirements for performance excellence, and sharing of information on successful performance strategies and the benefits derived form implementation of these strategies.

Appearance of the Award:

The award, composed of two solid crystal prismatic forms, stands 14 inches tall. The crystal is held in a base of black, anodized aluminum with the award winner’s name engraved on the base. A solid bronze, 22-karat, gold-plated, die-struck medallion is captured in the front section of the crystal. The medal bears the inscriptions: “Malcolm Baldrige National Quality Award” and “The Quest for Excellence” on one side and the presidential seal on the other.

Category of the Award:

The award is traditionally presented by the president of the United States at a special ceremony in Washington, D.C., to companies in three categories:

- Manufacturing Companies

- Service Companies

- Small business

Also, to publicizing the receipt of the Award, recipients are expected to share information about their successful performance strategies with other U.S. organizations.

The Qualification to get the Award:

Businesses located in the United States may apply for Awards. Subsidiaries are defined as divisions of business units of larger companies. Subsidiaries must primarily serve either the public or businesses other than the parent company. For companies engaged in both services and manufacturing, classification is determined by the larger percentage of sales. Small businesses are independently owned with not more than 500 full-time employees.

The evaluation Process:

Members of the Board of Examiners evaluate the examination process. High-scoring applicants are selected for site visits by a Panel of Judge recommend Award recipients to the Secretary of commerce from among the applicants’ site visited. Applicants receive a written feedback summary of strengths and areas for improvement in their quality management. The American Society for Quality Control assists in the administration of the examination process.

The evaluation Criteria:

The Malcolm Baldrige National Quality Award Criteria are the basis for making Awards and for giving feedback to applicants. The Criteria has three important roles in strengthening U.S. competitiveness. (1) To help improve performance practice and capabilities. (2) To facilitate communication and sharing of best practice information among and within organizations of all types based upon a common understanding of key performance requirements. (3) To serve as a working tool for managing performance, planning, training, and assessment. The Criteria was to design to help companies enhance their competitiveness through delivery of ever-improving value to customers, resulting in marketplace success; and improvement of overall company performance and capabilities.

Malcolm Baldrige Award Criteria perhaps provide the most acceptable approach to adoption of TQM in any organization. These criteria are built upon a set of ten core values and concepts.

Customer-driven Quality

Customers judge quality. All product and service characteristics that contribute value to customers and lead to customer satisfaction and preference must be a key focus of a company’s management system. Value, satisfaction, and preference may be influences by many factors throughout the customer’s overall purchase, ownership, and service experiences. These factors include the company’s relationship with customers that help build trust, confidence, and loyalty.

Customer-driven quality is thus a strategic concept. It is directed toward customer retention and market share gain. It demands constant sensitivity to emerging customer and market requirements, and measurement of the factors that drive customer satisfactions and retention.

Leadership

A company’s senior leaders need to set directions and create a customer orientation, clear and visible values, and high expectations. The leaders’ basic values and commitment need to include areas of public responsibility and corporate citizenship. The leaders need to take part in the creation of strategies, systems, and methods for achieving excellence and building capabilities. The senior leaders need to commit to the development of the entire work force and should encourage participation and creativity by all employees.

Continuous Improvement and Learning

Achieving the highest levels of performance requires as well-executed approach to continuous improvement. The term “continuous improvement” refers to both incremental and “breakthrough” improvement. The approach to improvement needs to be “embedded” in the way the company functions Thus improvement is driven not only by the objective to provide better products and services, but also by the need to be responsive and efficient both conferring additional marketplace advantage. To meet these objectives, continuous improvement must contain cycles of planning, execution, and evaluation. This requires a basis preferably a quantitative basis or assessing progress and for deriving information for future cycles of improvement.

Employee Participation and Development

A company’s success in improving performance depends increasingly on the skills and motivation of its work force. Employees’ success depends increasingly on having meaningful opportunities to learn and to practice new skills. Companies need to invest in the development of the work force through ongoing education, training, and opportunities for continuing growth. Such opportunities might include classroom and on-the-job training offers a cost effective way to train and to better link training to work processes. Work force education and training programs may need to utilize advanced technologies, such as electronic support systems and “information highways “. Addressing these challenges requires acquisition and use of employee-related data on skills, satisfaction, motivation, safety, and well-being.

Fast Response

Success competitive markets increasingly demands ever-shorter cycles for new or improved product and service introduction. Also, and more flexible response to customers is now a more critical requirement. Major improvement in response time often requires simplification of work organization and work processes should be among the key process measures. There are other important benefits derived for this focus: response time improvements often drive simultaneous improvement in organization, quality, and productivity. Hence it is beneficial to consider response time, quality, and productively objectives together.

Design Quality and Prevention

Business management should place strong emphasis on design quality problem and waste prevention achieved through building quality into products and services and into products and services and into production and delivery processes. In general, costs of preventing problems at the design stage are much lower than costs of correcting problems, which occur “downstream”. Meeting the demands of rapidly changing markets requires that companies carry out stage-to-stage coordination and integration of “concurrent engineering” of functions and activities from basic research to commercialization. Consistent with the theme of design quality and prevention, continuous improvement needs to emphasize interventions “upstream’ at early stages in processes. This approach yields the maximum overall benefit of improvement and corrections. Such upstream intervention also needs to take into account the company’s suppliers.

Long Range Outlook

Pursuit of market leadership requires a strong future orientation and a willingness to make long-term commitments to all stakeholders’ customers, employees, suppliers, stockholders, the public, and the community.

Planning needs to anticipate many types of changes including those that may affect customers’ expectations of products and services, technological developments, changing customer segments, evolving regulatory requirements, community/societal expectations, ands trusts by competitors.

Plan, strategies, and resource allocations need to reflect these commitments and changes. A major part of the long-term commitment is developing employees and suppliers, fulfilling public responsibilities, and serving as a corporate citizenship role model.

Management by Fact

A modern business management system needs to be built upon a framework of measurement, information, data and analysis. Measurements must derive from the company’s strategy and encompass all key processes and the outputs and results of those processes. Facts and data needed for performance improvement and assessment are of many types, including: customer, product and service performance, operations, market, competitive comparisons, supplier, employees-related, and cost and financial.

Analysis refers to extracting larger meaning from data to support evaluation and decision-making at various levels within the company. A major consideration in the use of data and analysis to improve performance involves the creation and use of performance measures or indicators. Performance measures or indictors are measurable characteristics of products, services, processes, and operations the company uses to track and improve performance.

Partnership Development

Companies should create partnership with customers, employees, labor unions, suppliers and educational organizations. Often partners seek to develop long-term objective and approaches for regular communication to evaluate progress in achieving those objectives. Companies should seek to build internal and external partnerships to better accomplish their overall goals. Internal partnerships might include those that promote labor-management cooperation, such as agreements with unions.

Agreements might entail employees’ development, cross-training, or new work organizations, and such high performance work teams. External partnership may be with customers, suppliers, and education organizations or a variety of purposes, including education and training. An increasingly important kind of external partnership is the strategic partnership alliance. Such partnership might offer a company entry into new markets or a basis for new products or services. In some cases, joint education and training initiative could offer a cost-effective means to help ensure the success of an alliance.

Corporate Responsibility and Citizenship

A company’s management should stress corporate responsibility and citizenship. Corporate responsibility refers to basic expectations of the company business ethics and protection of public health, safety, and the environment. Health, safety, and environmental consideration need to take into account the company’s operations as well as the life cycles of products and services. Companies need to address factors such as resource conservation and waste reduction at their source.

Corporate citizenship refers to leadership and support within reasonable limits of a company’s resources of publicly important purposes, including the above mentioned areas of corporate responsibility. Such purposes might include education improvement, improving health care value, environmental excellence, resource conservation, and community services, improving industry and business practices, and sharing nonproprietary quality-related information.

Results Orientation

A company’s performance system needs to focus on results. Results ought to be guided by and balanced by the interests of all stakeholders’ customers, employees, stockholders, suppliers and partners, the public, and the community. To meet the sometimes conflicting and changing aims that balance implies, company strategy needs to explicate address all stakeholders requirements to ensure that actions and plans meet the differing needs and avoid adverse impact on the stakeholders.

The core Value & the concept of the Award:

The core value and concepts of Malcolm Baldrige Award criteria are embodied in seven categories:

Senior Executive Leadership (125 points)

The leadership category examines how an organization’s senior leaders address values and performance expectations, as well as a focus on customers and other stakeholders, empowerment, innovation, learning, and organizational directions. Also examined is how the organization addresses its responsibilities to the public and supports its key communities.

This Item addresses how the company’s senior executive set strategic directions and build and maintain a leadership system conducive to high performance, individual development, and organizational learning. Executive leadership needs to take into account all stakeholders customers, employees, suppliers, partners, stockholders, the public, and the community.

A company’s senior leaders need to set directions and create a customer orientation, clear and visible values, and high expectations. The leaders’ basic values and commitment need to include areas of public responsibility and corporate citizenship. The leaders need to take part in the creation of strategies, systems, and methods for achieving excellence and building capabilities. The senior leaders need to commit to the development of the entire work force and should encourage participation and creativity by all employees.

Strategic Quality Planning (85 Points)

The strategic planning category examines the organization’s strategy development process, including how it develops strategic objectives; action plans, and related human resource plans. Also examined are how plans are deployed and how performance is tracked.

Strategic Quality Planning addresses strategic and business planning and deployment of plans, with a strong focus on customer and operational performance requirements. The Category stresses that customer-driven quality and operational performance excellence are key strategic business issues, which need to be an integral part of company planning. Specially, customer-driven quality is a strategic view of quality.

Customer and market focus (85 points)

The customer and market focus category examines how the organization determines requirements, expectations, and preferences of customers and markets. Also examined is how it builds relationships with customers and determines their satisfaction.

Customer Focus and Satisfaction is the focal point within the Criteria for understanding in detail the voices of customers and the marketplace. Much of the information needed for this understanding comes form measuring results and trends. Such results and trends provide hard information on customs’ view and their marketplace behaviors. This provides a useful foundation for setting priorities and focusing improvement activities. The results and trends offer means to determine whether or not priorities and improvement activities are appropriately directed.

Information and analysis (85 points)

The information and analysis category examines the organization’s performance measurement system and how it analyses performance data and information.

Information and Analysis is the focal point within the criteria for all key information to drive the improvement of overall performance. In simplest terms, is the “brain center” for the alignment of a company’s information system with its strategic directions. The Category addresses the information and analysis requirements for performance improvement based upon the improvement of key processes.

Human resources (85 points)

The human resource focus category examines how the organization enables employees to develop and utilize their full potential, aligned with the organization’s objectives. Also examined are the organization’s efforts to build and maintain a work environment and an employee support climate conducive to performance excellence, full participation, and personal and organizational growth.

Human Resource Development and Management is the focal point within the Criteria for all key human resource practices those directed toward the creation of a high performance workplace. The Category addresses human resource development and management in an iterated way. This integration is concerned with how well the human resource practices tie into and are aligned with the company’s strategic directions.

Process management (85 points)

The process management category examines the key aspects of the organization’s process management, including customer-focused design, product and service delivery, support, and supplier and partnering processes involving all work units.

Management of process quality is the formal point within the Criteria for all key work process. Built into the Category are the central requirement for efficient and effective process management effective design, a prevention orientation, evaluation and continuous improvement, linkage to suppliers and overall high performance.

Business results (450 points)

The business results category examines the organization’s performance and improvement in key business areas — customer satisfaction, product and service performance, financial and marketplace performance, human resource results, supplier and partner results, and operational performance. Also examined are performance levels relative to competitors.

Business Results provides a results focus for all processes and process improvement activities. Through this focus, the Criteria’s dual-purpose superior company performance reflected in productivity and effective indicators is maintained. Thus provides “real time” information for evaluation and improvement of process, aligned with overall business strategy.

The results and trends offer means to determine whether or not priorities and improvement activities are appropriately directed.

The Award Winners:

The Award have been presented to different Companies,

1988: Motorola & Westinghouse

1989: Milliken & Company, Xerox

1990: Cadillac Motor Car Division,

1991: Marlow Industries,

1992: AT&T,

1993: Ames Rubber Corporation,

1994: AT&T Consumer Communications, and

1995 Armstrong World Industries.

Winning companies are required to share their successful quality strategies at the annual Quest for Excellence Conference.

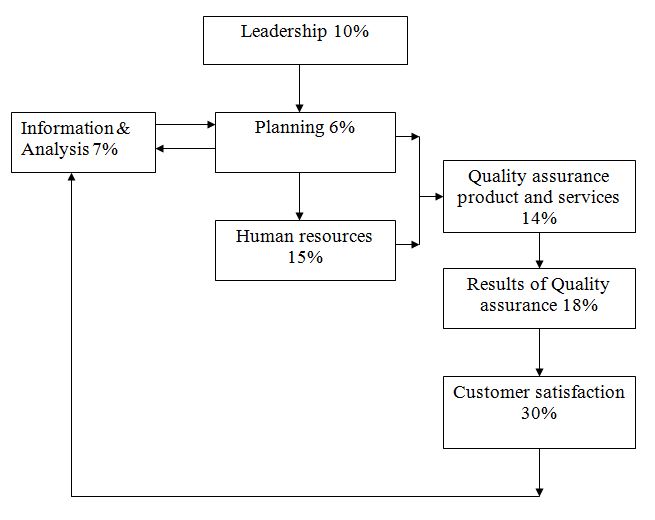

Examination Categories for the Malcolm Baldrige National Award

Examination categories, items, and point values for the Malcolm Baldrige National Quality Award

1991 Examination Categories/Items Maximum Points

1.0 Leadership 100

1.1 Senior executive leadership 40

1.2 Quality values 15

1.3 Management for quality 25

1.4 Public responsibility 20

2.0 Information and Analysis 70

2.1 Scope and management of quality data and information 20

2.2 Competitive comparisons and benchmarks 30

2.3 Analysis of quality data and information 20

3.0 Strategic Quality Planning 60

3.1 Strategic quality planning process 35

3.2 Quality goals and plans 25

4.0 Human Resource Utilization 150

4.1 Human resource management 20

4.2 Employee involvement 40

4.3 Quality education and training 40

4.4 Employee recognition and performance measurement 25

4.5 Employee well being and morale 25

5.0 Quality Assurance Products and Services 140

5.1 Design and introduction of quality products and services 5

5.2 Process quality control 20

5.3 Continuous improvement of process 20

5.4 Quality assessment 15

5.5 Documentation 10

5.6 Business process and support service quality 20

5.7 Supplier quality 20

6.0 Quality result 180

6.1 Product and service quality result 90

6.2 Business process, operational, and support service quality results 50

6.3 Supplier quality results 40

7.0 Customer Satisfaction 300

7.1 Determining customer requirements and expectations 30

7.2 Customer relationship management 50

7.3 Customer service standards 20

7.4 Commitment to customer 15

7.5 Complaint resolution for quality management 25

7.6 Determining customer satisfaction 20

7.7 Customer satisfaction results 70

7.8 Customer satisfaction comparison 70

TOTAL POINTS 1000

Source : 1991 Application Guidelines Malcolm Baldrige National Quality Award, U.S Department of Commerce, National Institute of Standards and Technology, Gaithersburg, MD. (1991).

Bibliography

Chandra, Mahesh “Total quality management in management development” Jornal of Management Development 1993: vol. 12 p:19-31.

J.S. Finlay. “ISO 9000, Malcolm Baldrige Award Guidelines” Quality System Update Aug. 1992:

Cap, Frank. “Quest For Excellence VII” Journal of Research of the National Institute 1993: vol. 100.

Access to Netscape “Malcolm Baldrige National Quality Award” http://www.nist.gov/quality-program/