An ecological protective coating is made of alternating layers of sugar and silica, which is stronger but less expensive than possibly harmful beryllium shielding. The straightforward solution, which resembles the structure of a seashell, should reduce the cost of pulsed power plants and space satellites.

The discovery of an extraordinarily cheap material that is lightweight enough to protect satellites against debris in the cold of outer space, cohesive enough to strengthen the walls of pressurized vessels experiencing average Earth conditions, and heat-resistant enough at 1,500 degrees Celsius or 2,732 degrees Fahrenheit to shield instruments from flying debris begs the question: what single material could do all of this? The solution, discovered at Sandia National Laboratories, is as sweet as sugar.

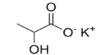

That’s because it’s sugar — very thin layers of confectioners’ sugar from the supermarket, burned to a condition known as carbon black, sandwiched between only slightly thicker layers of silica, the most prevalent material on Earth, then baked. The end effect is similar to a fine layer cake, or more exactly, the organic and inorganic stacking of a seashell, with each layer assisting the next in containing and mitigating shock.

“A material that can endure a range of insults — mechanical, stress, and X-ray — can be used to tolerate tough environmental conditions,” said Sandia researcher Guangping Xu, who led the novel coating’s development. “That information has not been widely available. We believe our layered nanocomposite, which resembles the structure of a seashell, is the solution.”

Most importantly, Xu stated, “The self-assembled coating is not only light and strong, but it is also thermally stable enough to protect equipment in experimental fusion machines from their own created debris at temperatures of up to 1,500 degrees Celsius. This was the project’s original focus.”

“And that may only be the beginning,” said consultant Rick Spielman, senior scientist and physics professor at the University of Rochester’s Laboratory for Laser Energetics, who was responsible for the initial design of Sandia’s Z machine, one of the destinations for which the new material is intended. “There are probably a hundred applications we haven’t considered.” He imagines potential electrode applications that delay, rather than block, surface electron emissions. Contributing to the mission of nuclear survivability.

The self-assembled coating is not only light and strong, but it is also thermally stable enough to protect equipment in experimental fusion machines from their own created debris at temperatures of up to 1,500 degrees Celsius. This was the project’s original focus.

Guangping Xu

The coating, which can be layered on a variety of substrates without environmental problems, was the subject of a Sandia patent application in June 2021, an invited talk at a pulsed power conference in December 2021 and again in a recent technical article in MRS Advances, of which Xu is lead author.

The work was completed in anticipation of the increasing shielding that will be required to safeguard test objects, diagnostics, and drivers inside future pulsed power devices. Sandia’s pulsed-power Z machine, currently the most powerful X-ray producer on the planet, and its successors will undoubtedly require even more debris shielding against forces comparable to many sticks of dynamite bursting at close range. Chad McCoy prepares samples for Sandia’s Z machine.

Chad McCoy, a physicist at Sandia National Laboratories, puts sample coatings into holders on the Z machine. When Z fires occur, researchers will examine how effectively specific coatings protect goods stacked behind them. (Bret Latter photo) A high-resolution image is available by clicking the thumbnail.

“The enhanced shielding should benefit our nuclear survival mission,” said Chad McCoy, article author and Sandia physicist. “Z is the world’s brightest X-ray source, yet the amount of X-rays released is only a few percent of the overall energy generated. The remainder is debris and shock. When we strive to understand how matter interacts with X-rays, such as metals and polymers, we want to know if debris is hurting our samples or has affected their microstructure. We are currently at the limit of our ability to shelter sample materials from undesired insults, but more powerful testing equipment will require greater shielding, and this new technique may offer adequate protection.”

Other, less specialized uses remain possibilities.

Because comparatively little material is required to achieve the same resilience as heavier but less effective shielding currently in use to protect against collisions with space junk, the inexpensive, environmentally friendly shield is light enough to ride into space as a protective layer on satellites. “Spacecraft are continually bombarded by debris moving at a few kilometers per second, the same velocity as junk from Z,” McCoy explained. “We can make the debris barrier thinner and lighter by using this coating.”

When extra ounces are not an issue, thicker shield coatings are durable enough to strengthen the walls of pressurized vessels. Significant cost savings are expected.

The material cost to create a 2-inch diameter coating of the new protective material, 45 millionths of a meter and microns thick, according to Guangping, is merely 25 cents. A beryllium wafer, which is the closest match to the thermal and mechanical properties of the new coating and is used as a protective shield at Sandia’s Z machine and other fusion locations, costs $700 at current market prices for a 1-inch square, 23-micron-thick wafer, which is 3,800 times more expensive than the new film of the same area and thickness.

Both coatings can withstand temperatures well above 1,000 degrees Celsius, but the new coating is also environmentally friendly. Only ethanol is used to speed up the coating process. Beryllium creates toxic conditions, and its environs must be cleansed of the hazard after its use. How testing proceeded

The Sandia coating is strengthened by the notion of alternating organic and inorganic layers, which is important in seashell longevity. According to Sandia manager and article author Hongyou Fan, the organic sugar layers that have been burned to carbon blackwork as a caulk. They also prevent cracks from spreading through the inorganic silica structure and give layers of cushioning to boost mechanical strength, as documented in an earlier Sandia attempt to duplicate the seashell mode 20 years ago.

Greg Frye-Mason, Sandia campaign manager for the Assured Survivability and Agility with Pulsed Power, or ASAP, Laboratory Directed Research and Development mission campaign that funded the research, was skeptical of the carbon insertion at first.

“I thought that the organic layers would limit applicability since most degrade by 400 to 500 C,” he said. But when the carbon-black concept demonstrated robustness to well over 1,000 C, the positive result overcame the largest risk Frye-Mason saw as facing the project.

The number of layers in the first seashell-like coverings studied at Sandia ranged from a few to thirteen. After being heated in pairs, these alternating materials were forced against each other, causing their surfaces to crosslink. The interlaced nanocomposite layers of silica with the burnt sugar, known as carbon black after pyrolysis, were found to be 80 percent stronger than silica itself and thermally stable to an estimated 1,650 C. Later sintering studies demonstrated that layers self-assembled using a spin-coating method could be batch-baked and their individual surfaces still crosslinked successfully, eliminating the need to bake each layer individually. The more efficient method produced approximately the same mechanical strength.