In the ignition system of a spark-ignition engine, an ignition coil converts the battery voltage to the much higher voltages required to operate the spark plug(s). This burst of high-voltage electricity is then used by the spark plugs to ignite the air-fuel mixture.

An ignition coil is an internal combustion engine component that generates the high-voltage current required to ignite the air-fuel mixture in the engine’s cylinders. It essentially functions as a transformer, converting the battery’s relatively low voltage into the much higher voltage required by the spark plugs.

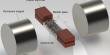

The ignition coil is made up of two sets of coils that are wound around an iron core. Older engines frequently use a single ignition coil whose output is directed to each cylinder by a distributor, a design that is still used by some small engines (such as lawnmower engines). Modern automobile engines frequently employ a distributorless system (such as coil-on-plug), in which each cylinder has its own ignition coil.

The ignition coil is made up of two wire coils wrapped around a soft iron core. These coils are referred to as the primary and secondary windings, respectively. The primary winding is connected to the low-voltage circuit of the battery, while the secondary winding is connected to the high-voltage circuit that powers the spark plugs.

When the ignition system of the engine is turned on, current flows through the primary winding, creating a magnetic field around the iron core. When the current is interrupted, the magnetic field rapidly collapses, inducing a high voltage in the secondary winding via electromagnetic induction. The high voltage from the secondary winding is then sent to the distributor or directly to the spark plugs, where it produces a spark across the spark plug gap, igniting the air-fuel mixture.

Diesel engines use compression ignition and thus do not have ignition coils.

An ignition coil is made up of an iron core surrounded by two coils (windings) made of copper wire. The primary winding has a few turns of heavy wire, whereas the secondary winding has thousands of turns of smaller wire and is insulated from the high voltage by enamel on the wires and layers of oiled paper insulation.

The ignition coil in modern vehicles is frequently controlled by an engine control unit (ECU), which precisely regulates the timing and duration of the spark. This allows for improved engine performance, greater fuel efficiency, and lower emissions.

When an ignition coil fails or malfunctions, it can cause engine misfires, rough idling, reduced power, and even engine stalling. In such cases, the faulty ignition coil must usually be replaced in order to restore proper engine operation.