Off-road enthusiasts frequently find themselves driving at low speeds and idling for extended periods of time. While this allows users to appreciate their surroundings and take in the beauty, it can also be taxing on the vehicle’s charging system. Most off-road vehicles’ standard alternators are built to work effectively at higher RPMs, leaving them unprepared to manage the power demands of different aftermarket components typically added by off-road enthusiasts.

Powerful lighting, recovery winches, electric fridges, and complex vehicle electronics all consume a large amount of power, putting a strain on the vehicle’s charging system. Inadequate alternator output can lead to exhausted batteries, decreased accessory performance, and probable breakdowns in remote regions.

Recognizing the problem, Powermaster Performance created a solution in the shape of their HPR series high output alternators. These alternators are intended for off-road vehicles such as Jeeps and other current engine platforms. They are designed to provide strong current output over a wide range of engine RPMs, including idle and low RPM conditions.

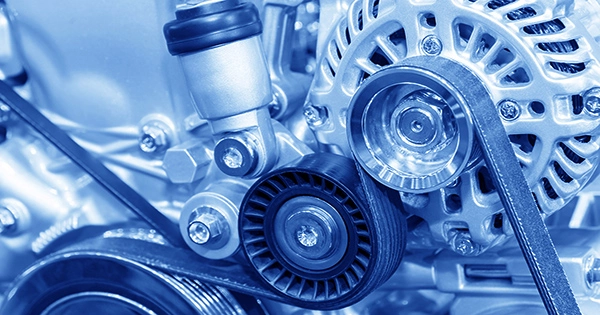

Powermaster’s HPR alternators’ fundamental innovation is their winding design. They use a distinct hairpin winding process, which allows for more material on the rotor and stator. This design improves the alternator’s output and efficiency, allowing it to provide significant current even at low RPMs. Furthermore, these alternators provide a balanced output from idle to high RPMs, making them perfect for off-road vehicles that operate at low idle and cruising engine speeds often.

The HPR alternators have the advantage of being direct-fit, which means they use a stock-diameter pulley and do not require overdriving. Overdriven alternators can generate excessive heat and wear, requiring a different belt length. Powermaster also comes with a factory-spec decoupler pulley, which ensures compatibility with the vehicle’s existing system.

It is critical to examine the charge connections and grounds when upgrading to a high-output alternator such as the HPR series. The charge wire should be long enough to accommodate the alternator’s current requirements. To achieve optimal current flow, a multi-strand copper wire is recommended. Furthermore, attaching a ground wire from the alternator to the engine block or negative battery terminal is advised, especially in vehicles with a lot of electronics, because good grounding is critical for reliable operation.

Finally, Powermaster Performance’s HPR series high-output alternators provide a solution to the insufficient alternator output that many off-road enthusiasts encounter. These alternators deliver strong current output at low RPMs, ensuring that off-road accessories work properly and reliably.