The Global Product Development and the Export and Import Activities of

Paxar Bangladesh Limited

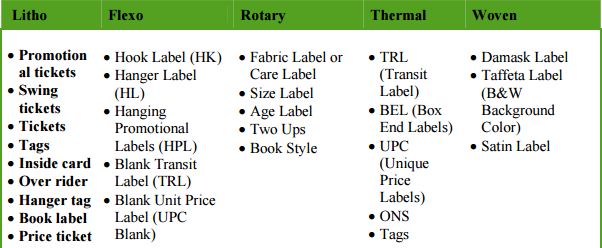

The study has done for the Paxar Bangladesh Limited. The report gives an overall idea about the activities of Paxar Bangladesh Limited and specially their export and import activities. Paxar Bangladesh Ltd is a subsidiary of Avery Dennison. It started its journey in Bangladesh in 2002. Since then it has been dominating in its own business sector. The main products of the company are of five types. These are- Litho, Woven, Flexo, Rotary and Thermal. The company imports its raw materials from foreign countries and exports its products in abroad.

Therefore, the export team of Paxar Bangladesh Ltd plays an important role in its success. This report entails information regarding the product development and oracle transformation process. Ever since Avery Dennison started its operation in Bangladesh, it never had any user friendly ERP system. They had one very basic ERP system called Texas which does not comply all the necessary function. So in order to set up this new ERP system the data used in Texas is required to transfer. This report also has enriched with the credit control activity of Paxar Bangladesh Limited. When the order is recorded, is updated to the AR that is sales report. Every day the sales report is updated and the data is used by the credit control department. According to the AR credit control sets the contracts as per the maturity of the contract. Then the follow up process starts. Before going to follow up, the credit manager sets a projection target for individual collector. The accumulated is the collection target of the specific month for the company. The individual collector starts the collection by a soft call to the customer on and after immediate maturity of the contract. The contract may be two types, sales contract and letter of credit. These contracts are 30 days, 45 days, 60 days or 90 days. If the first reminder is successful and the collector is satisfied then the collectors update the data to the “To Be Credit” file and submit to the credit manager. If it’s not then the collector goes for the second reminder, third reminder. At last if the customer is not able to pay the credit then the controller holds the goods by the fourth and final reminder. And the information is passed to the CC Team, Bank, Credit Control Manager. Thus the Paxar Bangladesh Limited operating successfully in Bangladesh as a subsidiary of Words renowned Avery Dennison Corporation.

Objectives of the Study

Broad Objective: The Broad or General Objective of this report is to have a thorough understanding about the Global Product Development and the Export-Import activities of Paxar Bangladesh Ltd.

Specific Objectives:

- To understand product development process.

- To understand the product lines and the types of products.

- Complying with Oracle System and understanding data validation.

- To be acquainted with the activity of the credit control department in an organization.

- To assess the company’s monthly collection target and to evaluate how much the company successful to achieve target collection.

- To identify how much credit policy effective for Paxar Bangladesh Ltd.

Methodology

Primary: The primary information is collected through face to face interview, observation and by participating in the recruitment process directly along with a survey amongst the employees of different departments.

Secondary: The secondary information collected from website, magazine, memorandum, journals, internal database and some other relevant sources. Both primary and secondary data sources were used to generate this report. Primary data sources are scheduled survey among the employees of the different departments of the organization, informal discussion with professionals’ and observation while accomplishing day to day jobs. The secondary data sources are website, different published reports, manuals, different publications of “Paxar/Avery Dennison”.

Preface:

Paxar Bangladesh Ltd. 100% Export oriented US based garments label manufacturing Company approved by Bangladesh export processing Zone (BEPZ). Paxar Bangladesh Ltd. has been motivated to provide “best-in-the-class” That’s why BEPZ recognized as a class “A” type investor in DEPZ.

Today, Paxar Bangladesh Ltd. Global Leads in Providing Innovative Merchandising Systems. Customers are World’s Major Retailers, Branded Apparel Companies & Contract Manufacturers. In order to Support the planned growth of its distribution, network and for its various business segment, Paxar Bangladesh Ltd. is currently looking for impressive goal oriented, enthusiastic, individual for various business operations.

Paxar Bangladesh Ltd. has built up a profitable and socially activated organization in the business field that helps to make the communities and economical condition of Bangladesh stronger and help people to achieve their imaginings. Paxar fulfill the purpose by reaching high standards in everything.

About Paxar

Paxar is a global leading organization in providing innovative merchandising systems for the retail and apparel industry. It is doing business in more than 75 countries all over the world and continues to expand worldwide. Paxar designs and manufactures tickets, tags and labels, and provides the technology, including the printers, software control systems and necessary suppliers for retail product identification. Paxar is generating new ideas, creating new products, making sales, purchasing raw materials and components, producing goods and providing service to Paxar’s customer. Paxar customers include the world’s major retailers, branded apparel companies and contract manufacturers.

Paxar focus is on working with their customers and adding value for them in everything Paxar’s do: Paxar help build their brands, manage their data and distribute their merchandise throughout supply chain. Within the framework of global operations, Paxar’s objectives are to complete aggressively but fairly deliver one-stop service to our customers. “From concept to checkout,” Paxar offers good working conditions and competitive compensation and benefits to all employees, comply with all laws and corporate governance obligations, and provide value to its shareholders. Within the retail supply chain; Paxar can handle Global Data Distribution, Security Solutions and Inventory Tracking needs. And to the final sale at the Retail In-Store level, Paxar offers Inventory Tracking System, Retail Control Systems, and Pricing Systems to meet the needs.

History

A Family Business Gets Underway

Paxar Corporation has a long, rich history of growth, innovation and timely response to industry trends. While the company has divisions dating back as far as the late 1800’s, the central Paxar story begins in 1918 with the launch of Meyer Tag and Label Company in New York City. Paxar’s founder, Leon Hershaft, a young immigrant from Europe worked at Meyer Tag and Label as a pressman. The company grew to become a well-respected business, and Leon was appointed General Manager. His brother Fred also joined the company, and in the 1940s, the two brothers bought the company. Other family members joined the business, including Arthur Hershaft, Leon’s oldest son who served as Paxar’s Chairman of the Board from 1986 to December 2006. During the 1960’s, as more and more retailers began to adopt self-service product packaging, Paxar began a secondary, carded visual packaging business in response. In 1969, it changed its name to Packaging Systems Corporation and became a publicly held company.

Innovation Leads to Growth

The manufacture of apparel tags and labels continued to prosper. This was in part driven by changes in textile legislation, which required clothing to be labeled with fiber content and care instructions. The opportunities for further growth were evident, and the company began working on a revolutionary, high-speed printing technique that would help label manufacturers effectively comply. In 1971, Paxar introduced its first patented printing system called Fasco™, which increased label printing output dramatically. Importantly, this new technology positioned the company to become the dominant printed label supplier to apparel manufacturers in the United States.

As other countries passed similar labeling laws, Paxar’s Fasco technology was licensed to printing companies in Europe, Asia and Africa. Not long after, the company engineered a hot stamp printing system incorporating the new technology.

This breakthrough promised even greater efficiencies for apparel manufacturers, who would benefit from printing labels as needed in their own facilities.

Acquisitions Expand Product Breadth and Global Reach

In 1987, an important strategic decision was made to alter the company’s business course. The carded visual packaging division was sold and resources were reallocated to growing the company’s tag and label business. At this time also, the company’s name was changed to Paxar Corporation.

Following this important milestone, Paxar opened its first European operations in England, Germany and Italy and an era of rapid growth ensued worldwide as the company sought to position itself as the vendor of choice for apparel companies and retailers. Over the next 17 years, businesses were acquired and companies established in Asia, Europe, the Middle East and Africa, Latin America and North America.

Paxar’s product and service offering also expanded to include woven labels, bar code products, graphic tags, soft apparel labeling, including transfers, and more.

New electronic printing systems were engineered such as the high-performance Monarch series of bar code printers and a ground breaking apparel labeling system called LOKPRINT. Just-in-time delivery options were enhanced; online services were introduced; and niche-retail labeling opportunities explored in areas as diverse as security labeling and food safety management.

Avery Dennison completes acquisition of Paxar Corporation

Pasadena, Calif. –June 15, 2007 — Avery Dennison Corporation (NYSE: AVY) announced that it completed its acquisition of Paxar Corporation today following the approval of the transaction by Paxar’s shareholders at its Annual Meeting on June 14, 2007.

On March 22, 2007, Avery Dennison announced a definitive agreement to acquire Paxar for $30.50 per share in a cash transaction valued at approximately $1.34 billion.

With the acquisition of Paxar, Avery Dennison’s Retail Information Services (RIS) business is expected to represent about 24 percent of Avery Dennison’s revenues – up from 12 percent before the combination. Paxar reported sales last year of $881 million. Avery Dennison said it will provide additional information on the anticipated financial benefits of the transaction, including expected sources and timing of cost synergies, during its regularly scheduled quarterly earnings release on July 24, 2007.

The purchase of Paxar has been initially funded through the commercial paper market, supported by a bridge facility arranged by JPMorgan Chase Bank, N.A. The Company remains committed to retaining a strong investment grade credit rating and to returning its financial ratios to target levels. The Company will work with JPMorgan Chase Bank, N.A., as arranger, and with the rating agencies to complete the permanent financing in the coming months.

About Avery Dennison Corporation

Avery Dennison is a global leader in pressure-sensitive labeling materials, office products and retail tag, ticketing and branding systems. Based in Pasadena, Calif., Avery Dennison is a FORTUNE 500 Company with 2006 sales of $5.6 billion. Combined with Paxar, Avery Dennison now employs more than 30,000 individuals in approximately 50 countries worldwide who develop, manufacture and market a wide range of products for both consumer and industrial markets. Products offered by Avery Dennison include: Fasson brand self-adhesive materials; Avery Dennison and Paxar brand products for the retail and apparel industries; Avery brand office products and graphics imaging media; specialty tapes, peel-and-stick postage stamps, and labels for a wide variety of automotive, industrial and durable goods applications.

Avery Dennison’s Value Proposition

- To be an industry leader with clear competitive advantages in large growth markets

- To provide a balanced strategy for value creating growth

- To maintain a strong balance sheet and cash flow combined with a disciplined investment strategy

- To focus on experienced management and high performance organization focused on the creation of shareholder value.

Locations of Avery Dennison

Avery Dennison is now serving the major portion of the world by its distinguished. The location of the company’s customers is provided below:

Types of product

Paxar/Avery Dennison is a part of the garments industry manufacturing the labels of the garments. They are in the business of manufacturing different types of label

RFID: Apart from the above products there is a special product on which the company is a global leader and the product is RFID (Radio Frequency Identification). As a global leader in RFID, our track-and-trace technologies can help accelerate inventory process speeds, prevent losses and improve efficiencies throughout the stages of our customers’ supply chains. Healthcare facilities, factories, libraries, airlines, retailers and document management services are just a few of the industries that have enhanced the effectiveness of their operations with our RFID solutions.

Strength and Weakness of the organization

The strength and weakness that helps the organization to draw the future plan of the business entity. The company runs SWOT analysis to update the organizational strategy.

Strength:

Value & Ethics: Values and Ethics are strictly followed by the employees of Paxar

Bangladesh Limited. The terms are introduced with the consideration of the organizational environment and structure.

RFID: As a global leader in RFID, its track-and-trace technologies can help accelerate inventory process speeds, prevent losses and improve efficiencies throughout the stages of our customers’ supply chains.

Market Leader: Paxar Bangladesh Limited is the market leader in the respected sector in Bangladesh. Almost all the top ranking local garments and branding textiles companies are the dependent on PBL for their world standard service.

Weakness:

Documentation: In Bangladesh the local customers are willing to have an urgent delivery with a short time period. But the company is not able to deliver the goods without documentation with the system support. So sometimes the company loses the local customers from their update services.

Time zone: Paxar Bangladesh Limited is interlinked with the practices of Avery Dennison. Because of regional operational conflict they have to face difficulties reporting with the parent company.

An overview of the Department

Avery Dennison has different activities around the world however in Bangladesh this company basically operates on the foundation of RBIS (Retail Branding information Solution). All the departments here work based on RBIS. There are several divisions among which the activities of Avery Dennison are divided. The organization follows a horizontal hierarchy for the ease of decision making process and minimization of complexity. Currently the functional departments of Avery Dennison are Commercial, HR & Administration, Finance and IT. The Commercial Division is consisted of five more departments such as Customer Service (CS), Factory Sales (FS), RBO Sales, Global Product Development (GPD) and Technical Sales (TS).

Global product development

Globalization pressures have begun to have a major impact on the practice of product development in Avery Dennison. This is a new paradigm which has emerged whereby Avery Dennison is utilizing skilled engineering teams dispersed around the world to develop products in a collaborative manner. Best practice in product development (PD) is now rapidly migrating from local, cross-functional collaboration to a mode of global collaboration. Global product development (GPD) therefore represents a major transformation for business, and it applies to a broad range of industries.

By 2000, Global Product Development in Avery Dennison had become widely accepted that highly effective product development included co-location of cross-functional teams to facilitate close collaboration among engineering, marketing, manufacturing and supply-chain functions. Co-located PD teams could concurrently execute the range of activities involved, from understanding market and customer needs, through conceptual and detailed design, testing, analysis, prototyping, manufacturing engineering and post sales technical product support/engineering. This concurrent engineering practice resulted in better product designs, faster time to market and lower-cost production. PD activities were generally located in corporate research and development centers, which maintained linkages to manufacturing sites and sales offices around the world.

By contrast, the emerging best practice in PD today utilizes a highly distributed, networked development process facilitated by a fully digital PD system. Global product development combines certain centralized functions with some engineering and related PD functions distributed to other sites or regions of the world. This practice may involve outsourced engineering work along with captive offshore engineering facilities. The benefits of GPD are beginning to become clear. They include greater engineering efficiency (through utilization of lower-cost resources), access to technical expertise that is distributed internationally, design of products for more global markets and more flexible PD resource allocation.

GPD (Global Product Development) Bangladesh:

In Bangladesh GPD does a great effort in terms of developing and designing the products. Some of the main facts of Global Product Development in Bangladesh is given below-

Globally distributed teams.

- Takes advantage of engineering in multiple geographic locations, including low, medium and high-cost regions.

- Uses an entirely digital PD process to facilitate distributed, collaborative engineering features a highly distributed, networked development process facilitated by a fully digital PD system.

Avery Dennison has built its GPD for the below reasons-

- Lower Cost: Avery Dennison strives to reduce PD operating costs by redistributing activities to take advantage of labor arbitrage or to access more affordable capabilities.

- Improved Process: Many engineering managers can recall the key lesson learned from both the 1980s emphasis on design for manufacturing (DFM) and the 1990s emphasis on time to market (TTM). This lesson was that co-locating development teams — particularly the design engineers with the manufacturing engineers — yielded both the cost benefit of DFM and the agility benefit of TTM. The prospect of moving design engineering to global manufacturing locations can be attractive.

- Global Growth: Locating some PD activities in selected international locations can give access to critical information about markets in those regions. By using local engineers, companies make direct connections with potential new markets.

- Technology Access: Avery Dennison is using GPD to develop integrated PD processes that include engineers in regions where critical new technology has been developed and where technical experts reside.

Complying with Export-Import Activity

Paxar Bangladesh Ltd is 100% export and import oriented business organization. They need to import the raw materials from abroad and export the products to foreign countries. Paxar Bangladesh Ltd has an expert team on Supply Chain Management who are basically controlling this important tasks of export and import. I had to work in Credit Control Team of Paxar Bangladesh Ltd for my internship purpose. Therefore, I could not get that much practical knowledge on export and import activities of PBL. For making this report fruitful, I talked with Senior Executive of export team Mr. Taufiq Elahi who provided me with necessary information. According to him, they maintain a safety stock in hand when they make any import order. The reason is that they do not want to hamper the normal production schedule by any inconvenience. When they select the suppliers, they think about the low cost provider with maximum quality. Since it is 100% export oriented organization, they need to export their products in foreign countries. When they select buyers, they think about the highest price provider. At the same time, they need to think about other benefits as well. For example- which buyer can maintain long-term relationship, which buyer is willing to buy a huge quantity etc. They basically exports five types of products. These are Litho, Woven, Thermal, Rotary and Flexo. However, for both export and import they need to follow the government rules and regulations strictly. PBL has their Factory in Savar EPZ. All of us know that in EPZ, the organization does the dealings of foreign business. More specifically, it is the place where the organization dispatches their produced products for exporting purpose.

Like other MNCs, their price is also affected by the price change in other countries of their wing. As a result, the export team needs to be very careful about this kind of information when making any agreement of buy or sell. In addition, any kind of discrepancy or misinterpretation of information can make the contract illegal or void. So, the export team always wants to give hundred percent of their effort. There can be a maximum difference of 99 cents in the contract value. Anything more than that will make the contract discrepancy.

For export and import purpose, PBL mostly use LC for the transaction benefits. The documentation charges and other charges are borne depending on the contract.

Method of payment:

Paxar has three types of payment systems for its customers, such as:

Through bank by letter of credit (L/C) or sales contract on exceptional case subject to approval by General Manager

Sales contact: The customer can pay in advance for which the account will be credited with the progress of delivery. But these advance can pay in two way:

- a) Dollar draft (If any order less then USD 1000 then Customer have to provide USD Bank Draft before taking delivery of the goods) and

- b) Telegraphic Transfer Company policies: To streamline the existing credit to customers and ensure the internal control Paxar have a clear guideline regarding credit for the customer. The following credit policy has been proposed to the customer

1) General Credit Terms: 60 Days

2) Extended Credit Terms: 90 Days

3) Fixing Credit Terms: Credit Control department will finalize credit rating report with the information about volume of business and L/C terms from sales &marketing and commercial department respectively. An approval from General Manager may need for this report.

4) Grace period: 3 working days for banking purpose

5) Credit limit: Maximum USD125k

6) Mode of payment: Bank Draft, Telegraphic Transfer in advance or by Letter of Credit (L/C) in US Dollars only.

7) On hold transactions: Under the following cases Paxar Bangladesh will stop to accept further order or deliver any shipment:

- If customer fails to clear payment of 2 (two) consignments within a month after expiry of the credit term, or;

- If customer fails to clear payment of consecutive outstanding of 2 (two) consignment after expiry of the credit term, or;

- If the maximum credit limit exceeds.

8) Standard L/C term: All the customers have to incorporate the following terms and condition in L/C to be acceptable to Paxar Bangladesh Ltd before taking delivery of the goods:

- Irrevocable Letter of Credit

- At-sight Or 60/90 days deferred

- L/C value should be minimum US$ 1000.00, otherwise only S/C is acceptable.

- Value payable in US dollars

- Delivery term is CFR Ex-factory

- Partial Shipment is allowed

- Presentation Period is 15 days.

9) Other Conditions:

- All Bank changes outside the Applicant’s counter from Beneficiary’s A/C

- Maturity will be counted from the date of negotiation

iii. Applicant will pay interest at LIBOR (in case of 60 days credit) + 1% (in case of credit period is 90 days.) for the credit period from the date of negotiation.

- Advise through HSBC, Dhaka main office.

If there is any exception of the L/C term and Paxar need to deliver then Customer Service have to justify the reasons and prior approval to be taken from General Manager before delivery of the goods.

Findings

While working at Paxar Bangladesh Ltd, I have attained to a newer of experience. After the collection and analysis of data, I have got some findings. These findings are completely from my personal point of view. Those are given below:

- The analysis of the target collection statement 2014 shows that the company sets a secure collection target.

- From the collection chart 2014 they are successful to achieve the estimated collection target. The standard deviation analysis shows that the STD less than one so this study shows the team have an excellent corporate performance.

- While setting the collection target the company has to report the Paxar Hong Kong Ltd, so sometime it becomes difficult to adjust credit policy with the reporting company.

- Paxar Bangladesh Ltd. follows the master credit policy set by the higher authority, 30 days, 45 days, 60 days, 90 days.

- Credit Control team of this company is very efficient about their work. In last year, December 2014 they collected US $6.5 million of their outstanding sales. It was the record target achievements of this company.

Recommendations

For the probable solutions of the identified problems ensure better progress to Paxar Bangladesh Ltd. in future. Some necessary steps are recommended below on the basis of collected data, observation, expert staff’s opinion and my knowledge and judgment:

- After completing the survey findings I recommend that customers are satisfied regarding Global Product Development of paxar Bangladesh Ltd.

- Delay of System Upload (KEA). KEA does not upload timely in many cases. That’s why CSO are not found any Idea about production stutas. That makes the customer Unhappy.

- GPD should have the involvements on production.

- Delay process Of QC Department.(layout after approved by the customer not need to recheck the Positives or Negatives).

- Need to improved KEA system.

- Need to recruit Skilled Operator.

- Increase more machine and machinery to improve the production capacity of the factory.To maintain the technological support strong, hire more efficient IT expert.

- Though the over all process of documentation has decreased from 8 hours to 2 hours, the company should be more concern about decreasing the process timing.

- The company is following the standard credit policy but in the Bangladeshi perspective it will be more effective if it is relaxed by 7 days or 15 days.

- Software coordination will decrease the documentation timing. So the software’s should be linked up.

Conclusion

Paxar Bangladesh is the newest arena of Paxar family. They started their operation from 2002. In eleven years, they have established themselves as the leading labeling company of our country. All the departments are doing well to reach their goal. The environment of working in Paxar is really different from other organizations. The environment is very friendly and informal. So, there is no communication gap between the superiors and the juniors. There is also no communication gap between the departments. All are very cooperative to solve other problems. If they keep their current growth rate they will capture maximum portion of labeling market of our country.