Foldable phones are widely used today. University of Wisconsin-Madison and University of Texas at Austin researchers could usher in a new era in which these bendy devices can smoothly integrate with portions of the human body utilizing models that anticipate how effectively a flexible electronic device will adapt to spherical surfaces.

Future technologies could help restore eyesight, such as a flexible bioelectronic prosthetic retina implanted in a person’s eyeball or a smart contact lens that continuously monitors blood glucose levels.

“With our powerful simulation model, we can now predict the conformability immediately, which dramatically speeds up the design process for flexible electronics,” says Ying Li, an associate professor of mechanical engineering at UW-Madison, whose research group developed the computational models. “The simulation results give very clear guidance for experimentalists, who can now determine the optimal design without needing to do a lot of extremely time-consuming experiments.”

The researchers detailed their work in a paper published April 19, 2023, in the journal Science Advances.

Bioelectronic devices need to be in very close touch with living tissue and keep from buckling or creasing in order to function as planned. The human body is covered in surfaces known as “non-developable surfaces” that can’t be flattened without breaking or creasing. Researchers have struggled to make flexible electronics to entirely conform to these surfaces.

With our powerful simulation model, we can now predict the conformability immediately, which dramatically speeds up the design process for flexible electronics. The simulation results give very clear guidance for experimentalists, who can now determine the optimal design without needing to do a lot of extremely time-consuming experiments.

Professor Ying Li

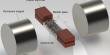

In this study, the research team carefully investigated how circular polymer sheets (which mirror the mechanical properties of flexible electronics), as well as partially cut circular sheets, conform on spherical surfaces using a combination of experimental, analytical, and computational methodologies.

The researchers were able to derive a practical formula from the analysis of those findings that explains the underlying physics and forecasts the conformability of flexible electronics.

“The results from our three different methods all pointed to the same physics, which is exciting,” says Nanshu Lu, a professor in the Department of Aerospace Engineering and Engineering Mechanics at the University of Texas at Austin, who led the experimental research. “We formulated a very simple mathematical equation to guide the design of flexible electronics for maximum conformability, and this should have a significant impact in the field.”

The researchers also showed a straightforward and sophisticated technique for significantly improving the flexibility of flexible sheets on spherical surfaces. In order to increase the circular sheet’s conformability from 40% to more than 90%, the researchers made the simplest radial incisions in it, drawing inspiration from the Japanese art of kirigami, which involves cutting and folding paper.

According to Li, this development will spur innovation in the sector by making it possible for numerous other researchers to create better flexible electronics.

“This is the first work to provide a full picture to understand the complex process of how flexible electronics conform to these complicated surfaces,” Li says. “This advance will pave the way for all the future studies in the area of developing bioelectronics that can better conform to the human body.”