Leather is a multibillion-dollar industry that requires more than 3.8 billion bovine animals per year – one for every two people on the planet – to sustain production. While the products – clothing, shoes, furniture, and so on – can be quite elegant and long-lasting, the environmental impact of leather production has been severe, resulting in deforestation, overuse of water and land, pollution, and greenhouse gas emissions.

Tufts University School of Engineering researchers set out to find an alternative to leather with similar texture, flexibility, and stiffness, but with a focus on materials that are sustainable, non-toxic, and environmentally friendly. It turns out that we’ve been wearing that material all along – silk – but instead of weaving the silk into fabric, Tufts engineers were able to break down the fibers from silkworm cocoons into their protein components and re-purpose the proteins to form the leather-like material. A study published in the journal Materials & Design describes the process of creating silk-based leather.

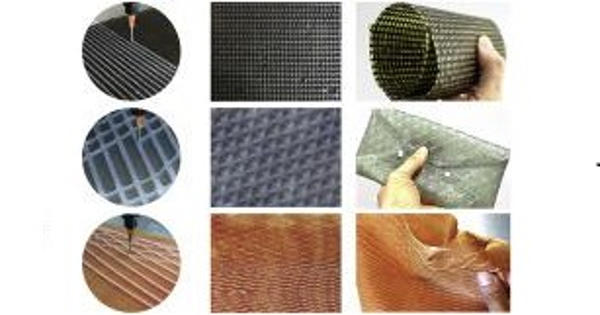

The silk-based leather can be printed in a variety of patterns and textures, has physical properties similar to real leather, and can withstand the folding, piercing, and stretching commonly used to create leather goods, including the ability to stitch together pieces of material and attach hardware such as rivets, grommets, handles, and clasps.

Engineers have created an environmentally friendly leather alternative made from silk. The material can be printed into different patterns and textures, has similar physical properties to real leather, and can withstand the folding, piercing, and stretching typically used to create leather goods.

“Our work is centered on the use of naturally-derived materials that minimize the use of toxic chemicals while maintaining material performance in order to provide alternatives for products that are commonly and widely used today,” said Fiorenzo Omenetto, Frank C. Doble Professor of Engineering at Tufts School of Engineering, director of the Tufts Silklab where the material was created, and co-responsible for the research. “We are making progress toward this goal by using silk, as well as cellulose from textile and agricultural waste and chitosan from shellfish waste, and all of the relatively gentle chemistries used to combine them.”

There is, of course, an existing portfolio of alternative leathers developed by industry and the research community, with a focus on using agricultural byproducts or regenerated materials with a lower environmental impact and animal raising. Leather-like materials made from petroleum (polyurethane leather or “pleather”), tree bark, pineapple husks, plant oils, rubber, fungi, and even cellulose and collagen produced by bacterial cultures are among them.

Tufts’ silk-based leather has some distinct advantages over all of these methods. Aside from being made from dissolving silk fibers, the manufacturing process is water-based, employs only mild chemicals, is carried out at room temperature, and produces mostly non-toxic waste. Silk leather can be fabricated using computerized 3D layering with the ability to create regular micropatterns that can tune the material’s strength and flexibility, print macro patterns for aesthetics (e.g. a basketweave), and non-regular geometrical patterning to mimic the surface texture of real leather. The resulting materials, like leather, are strong, soft, pliable, and durable, and like natural leather, they are biodegradable once they enter the waste stream.

In fact, the silk-leather products could be re-dissolved and regenerated into its gel-like stock matter to be re-printed into new products

Silk fibers, which are commonly used in the textile industry, are used to begin the process of making silk leather. These fibers are composed of silk fibroin protein polymers and can be disassembled into individual protein components in a water-based slurry. To provide flexibility and strength to the material, a base layer of chitosan containing non-toxic plasticizer glycerol and dye is extruded through a tiny bore nozzle onto a surface. Chitosan is derived from natural sources such as crab, lobster, and shrimp shells. On top of the base layer, a layer of silk fibroin combined with a plasticizer and a thickener (from vegetable gum) is printed.

Extruding the fibroin slurry through the printer nozzle creates shear forces that may help to arrange the proteins in a way that strengthens the material, making it ductile rather than brittle, and mimics the natural extrusion that occurs in a worm’s or spider’s silk gland. Changing the silk layer’s printed pattern can provide a variety of appearance, tunable strengths, and other physical properties.

When compared to other methods such as injection molding or subtractive manufacturing, the printing method, also known as “additive manufacturing,” is known to be very conservative in terms of material use and waste produced (like carving or shaving from a block).

Tufts’ Silklab has created a wide range of other products from silk, including implantable medical devices and architectural materials that can sense and respond to their surroundings by changing color. Indeed, much of the technology developed in the lab to derivatize silk proteins can be applied to silk-based leather, such as attaching and embedding molecules that can sense and respond to their surroundings.

“That’s the advantage of using silk protein over other methods – it has a well-established, versatile chemistry that we can use to tune the qualities of the material and embed smart elements like sensing molecules,” said Laia Mogas-Soldevila, former Silklab research fellow, now an assistant professor of Architecture at the University of Pennsylvania Stuart Weitzman School of Design, and first author of the paper. “Thus, while there are numerous options for leather-like materials, silk-based leather has the potential to be the most amenable to innovative designs.”