Analysis of the Cement Industries of Bangladesh

in respect Premier Cement Mills Limited

Premier Cement Mills Ltd is one of the leading cement companies of the country. The company was started off by top ranking businessmen who had long years of experience in the cement business. Premier Cement Mills Ltd was incorporated on 14th October 2001 and it started its production on 12th March 2004 commercially. The company is well known for producing quality cement at a low price. The head office and the commercial building of Premier Cement Mills Ltd is located in TK Bhaban, Karwan Bazar, Dhaka.

The other office of PMCL is located in Chittagong. The team consists of three leading groups of Bangladesh which are T.K Group of Industries, Seacom Group and Jahangir & Others. The Board of Directors of the company consists of members from each of the above three groups. A total number of 450 employees work in PMCL. Currently, the company runs with an annual production capacity of 9 Lacs tons (per Month 75,000 tons).

The company manufactures two types of cement which are the Portland Composite Cement and the Portland Pozzolana Cement which is made solely for exporting. The present production capacity of the ongoing project of the year 2010 of Premier Cement Mills Ltd is 1,200,000.00 tons. The company uses the European Standard Method (ESTM) to manufacture their products. They are also one of the few companies in Bangladesh who use European machineries and technologies to produce their products.

Premier Cement Mills Ltd has its own mother vessels, lorries, trucks and vans through which they deliver their products to their customers. They also export their products to India and Srilanka every year. The company has recently acquired a factory of a cement company in Chittagong which will help them to expand and increase their production in the near future.

The report consists of a job part where I have tried to explain about the practical experiences that I got during my internship. The company had given me the opportunity of working in all the departments of their corporate office which were the Information Technology Department, Finance and Administration Department, Human Resource Department, Operations & Maintenance Department, Quality Assurance Development Department, Logistics and Distributions Department and the Marketing and Sales Department. . I had worked with each of these departments to learn about their jobs closely and to get an idea of how the company works overall. Some of the specific works and job responsibilities that I was assigned to were tasks like preparing and managing the Order Processing System (OPS) , analyzing sales figures, contributing in the decision making and the planning of activities taken to increase sales, involving with the setting of the HR department, assisting in managing time schedules, recording and tracking the sales call from the distribution channel, preparing documentation for exports, assisting in making policies for the health/medical benefits for factory workers, creating Product Invoice , interacting with customers in Customer Service Department, participating in the re-launching of the Cash ++ Offer 12 & the Eid2Eid Offer, reporting on price analysis and price fixation, working with the CSR marketing team and doing a comparative analysis of the websites of the competitors of PMC. While doing these jobs, I came across some areas where I have tried to find out some scope of improvement and thus gave some recommendations accordingly.

Objective

The main objectives of this report are:

- To have a practical experience of Job life.

- To find out the relevance and application of the theoretical knowledge in practical life.

- To know about the real life scenarios and problems that occurs in a workplace which however cannot be understood properly by reading books and studying in classrooms.

- To gain an in-depth knowledge about how a company (in this case a cement company) functions by utilizing its resources properly.

- To gain knowledge about the cement industry of Bangladesh.

Methodology

This report has been completed by taking information from different relevant sources. Some accounts have been taken by observing and working with the company itself.

However, this report also consists of a significant amount of data obtained from both primary and secondary sources.

Secondary data:

- For the secondary data, I have used the intranet of Premier Cement Mills Ltd which mainly consist of the data and the excel sheets of the company.

- I have also taken information from various reports which were provided to me by PMCL.

- In addition, I have taken some information from the internet as well. Primary data:

- Practical work experience at the different departments of PCM Ltd.

- Discussions and meetings with the employees of PCML regarding their feelings, opinions and feedback regarding Premier Cement.

- Interaction with some customers via telephone through which I could capture their perception about the company.

- Field visits to the factory of PMC Ltd, meeting with the engineers and masons and some brief visit to the cement shops.

Premier Cement Mills Ltd (PCML)

Premier Cement Mills (PCM) Ltd is one of the leading manufacturers of cement in Bangladesh. Premier Cement Mills Limited was incorporated on 14 October 2001 but they started their production commercially on 12th March 2004. Currently, the company runs with an annual production capacity of 9 Lacs tons (75,000 tons per Month). Their products are all around us, providing strength and durability to buildings of soaring dimensions, in infrastructure that speeds the lines of commerce and for housing that provides comfort and security to families across Bangladesh. The aim of the company is to relate their brand name in cement to best quality, dependability and technical excellence. The company employs about 450 employees out of which 330 workers works in the factory of West Muktarpur Munshiganj and in their registered office in Chittagong.

The remaining number of employee works in the Corporate Office of PCML which is located in Karwan Bazar, Dhaka.

The Company has purchased one of the most sophisticated plant and machineries entirely from its own funds, without any project borrowing. PCML has also purchased an ideal piece of Factory Land, measuring about 15 acres, at West Muktarpur, Munshiganj; Bangladesh. On the front side of the Land is Dhaka-Munshiganj Road and on the rear side is the river Shitalakhya, which meets the river Dhaleshwari about two kilometers down stream where both together falls at the mighty river Meghna. Thus the setting of this location provides a marvelous accessibility of both land and river for the factory site of the company.

With a total installed cement capacity of almost a million tons per year at Muktarpul, Munshiganj, the Company is recognized as a leading cement producer possessing an abundant supply of raw materials, low production cost and an energy efficient operation.

High quality and lower price are the main characteristics of Premier cement. Application of some special technology and presence of efficient workers enables to differentiate the company’s products from that of the other companies. These differentiating features include:

- State-of-the-art technology of grinding mill with Roll Press – ensures uniform particle size distribution.

- High chrome grinding media having very less wear rate, hence free iron content in cement resulting in good quality cement.

- Quality grinding with Closed-Circuit System.

- Own testing laboratories with modern equipments.

- The company owns ocean going vessels for clinker handling.

- The Cement is packed in its own bagging plant in both paper bags and PP (plastic) bags which are available as per the demand of the customer.

- Having adequate numbers of own fleet of covered transport for better distribution and services.

- Having adequate bulk carriers and portable silos.

Job Summary

A number of important issues and topics related to the cement industry in Bangladesh and Premier Cement mills Ltd have been discussed below in the project part. The first part of the project focuses on the various aspects of the Cement industry of Bangladesh. To start with, brief information regarding the concerned product “cement” has been included followed by historical background of the cement industry in Bangladesh. Moving on, some important incidents that took place in this industry over the last couple of years which has evolved the various scenarios of this industry have also been discussed. The list of the ranking of the current top ten Cement companies of Bangladesh has been given.

This part of the project ends with a brief analysis of the overall cement industry of Bangladesh. The second part of the project mainly focuses on the position of Premier Cement Mills Ltd compared to other cement companies in the industry. For a better understanding, a competitor’s analysis of PMCL has been included. Next, the situation of the various facet of PMCL and the cement industry has been discussed in details. The aspects that has been covered includes the products offerings, production capacity, technological impact, pricing, customers, promotional activities, export and import activities and lastly the sales and profits of PMCL and the other companies operating in the cement industry. This analysis is followed by some plans of PMCL that they are planning to implement in the near future, followed by a SWOT (strength, weakness, opportunity and threats) analysis of the company. Lastly considering all these points, I have discussed about some critical observations where I think that there is some scope of improvement. Based on these, I have given some recommendations to tackle these enduring issues within the industry

Description of the Project

Objective of the Project

The main objectives of the project are:

- To understand about the Cement Industry of Bangladesh

- The analyze the current scenario of Premier Cement in respect to the overall Cement Industry of Bangladesh

- The future plans of Premier Cement.

Industry History

Cement Industry, a relatively fast growing industry, is developing in pace with increasing building and construction activities. Cement has long been used as a bonding agent to unite particles or to cause one surface to adhere to another. Today hydraulic cements, of which Portland cement is most familiar, when made into a paste with water and aggregate, set and hardens as a result of chemical relations between water and the compounds present in cement. With good hydraulic cement, development of strength is predictable, uniform and relatively rapid.

Historically, Bangladesh did not depend much on cement. It also does not have enough natural resources for manufacturing it. The base materials traditionally used in house building and other construction required little use of cement. Gradual substitution of traditional building structures or patterns by modern high-rise ones has pushed up the use of cement. However, as the economy continues to remain agro based, construction sectors have not been able to gain momentum and as the infrastructure development is selective, cement remained product of low demand. A faster growth in demand for cement has been observed only since mid-1980s, especially with implementation of large infrastructure projects, increased pace of urbanization, construction of apartment buildings and multistoried shopping complexes in urban areas, and a shift in the taste of moneyed rural people for modern houses.

Private enterprises dominate production and import of cement to cater to the local market. The manufacturing of cement is based on both locally available raw materials and imported clinker. The mills that produce cement from imported clinker are located mostly around Dhaka, Chittagong, and Mongla. Local raw material based cement production depends on limestone deposits that lie in St Martins Island, Joypurahat areas and in the deposits in Sylhet. Some plants have the added advantage of being able to meet their needs for gas and clay from deposits close by.

Bangladesh has adopted EN197- 1:2000 as Bangladesh Standard, titled BDS EN 197- 1:2003. Under this Standard there are 27 products in the family of common cements, which are grouped into five main cement types as follows:

- CEM 1 Portland cement

- CEM 2 Portland- composite cement

- CEM 3 Blast furnace cement

- CEM 4 Pozzolanic cement

- CEM 5 Composite cement

The composition of each of the 27 products under the above five categories (indicating percentages by mass of the main constituents) are given in the table (refer to table 1). As the main constituent (% by mass) along with the strength class is printed on the cement bags, it is not easier for the consumers to select the type of cement that they require.

The evolving scenarios of the cement industry of Bangladesh

In the year of 1995, the government first gave permission for establishing cement industries in Bangladesh. However, this permission was given to the companies without any kind of thorough prior study of the industry. Thus the starting point of the establishment of the cement industry took place without the proper analysis of the demand and supply of cement for the country. Within the span of the next 2 to 3 years, the supply of cement coming into the country faced an expanded capacity of the product.

As time went by, the demand of cement increased as infrastructural development projects took place in Bangladesh. Most of the cement companies back then was import based that brought this product from other countries to meet the demand of their clients in Bangladesh. However, there were mainly four dominant players in the cement industry in the year 1998 that produced their own cement to meet the demand of their customers.

These companies were:

- Meghna Cement ( owned by Bashundhara group)

- Eastern Cement ( currently known as Seven Horse)

- Chatok Cement (Currently taken over by Heidelberg where the local brand is called Ruby)

- Chittagong Cement (which was initially owned by the government, currently known as Confidence Cement).

In the year 1999, the demand of cement rose to 3 million tones suddenly. To meet this demand the existing companies planned to increase their production capacity and more entrepreneurs became interested in venturing their business skills into this sector. Two big companies entered the cement industry in the year 2000 and 2001.Despite the emergence of cement companies in Bangladesh, the demand of the cement rose significantly, whereas the supply of the cement was insufficient to meet this demand. Till the year 2002, only one type of cement was available in Bangladesh which was the clinker based cement. This is known as the Ordinary Portland Cement (OPC) which is made as per the method known as the American Standard Method (ASM). From the year 2002, various types of cements became available in Bangladesh which helped the cement industry to provide differentiated and improved products to their customers in Bangladesh. The cement which is widely used from the year 2002 till now is the composite cement which is made by using the method of the European Standard Methods (ESM). The composite cement has many advantages over the clinker based cement .The composite cement consist of cements of different layers which is ideal for building the different types of structures in a building. The different layers of cement have been graded as per the strength provided by the cement. Holcim Black Cement was the first local company who started producing composite cement in Bangladesh. Currently, most of the companies can be identified as the grinding mills rather than just pure cement companies. Only Chatok (the oldest cement company) and Lafarge are the absolute cement producing companies in the country today. Over the time span of last five years, the growth in the cement industry has been 130%, however the total industrial growth has been 53% in the last one year (FY2009 to FY2010). Currently there are 31 cement companies operating in the cement industry actively. The total production capacity of all the companies for this year is more than 17 million ton and the current Industry Consumption is 12.5 million/annum (refer to table Present & Upcoming Capacity of Running cement industries in Bangladesh).

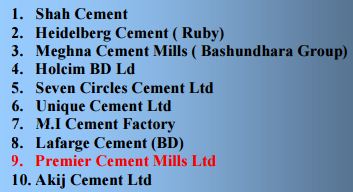

Ranking of the Cement Companies

31 cement companies are operating in Bangladesh. They vary from one another in terms of their production capacities, resources, technological application etc. The names of the top ten cement companies are listed below.

The cement industry came into picture in Bangladesh during the middle of 1980’s as some infrastructural development projects took place. However, the starting point of the cement industry took place began from the year 1995. Within the time span of a decade, the smaller companies shut down while the bigger ones expanded more and more, making a more dominant place for themselves in the market of cement today. The industry which was mainly import based till the year of 1999 to 2000, now not only makes their own cement but also exports their products to countries abroad as well.

The current statistics of demand and supply of cement in Bangladesh are given below:

Year 2010: Demand of cement = 12.5 m/tone per annum

Supply of cement = 18.5 m/tone per annum

According to some industrialists, it has been forecasted that these statistics are likely to change within the next two years only. The forecasted statistics are as follows:

Year 2012: Demand of Cement/ capacity = 21 million tone

Growth Rate= 13 to 14 million tone

Both the demand and the production capacity of cement are likely to increase within the next two years for similar reasons which are prevailing today. Some smaller companies with shut down (just like before) and the gibber companies will expand more and compete with one another vigorously. In addition, the present government of Bangladesh has allocated a huge amount for the Annual Development Project (ADP) budget for the upcoming infrastructural projects of the government to be located in Bangladesh. Some of these big projects which are/have undergone agreements are the construction of Padma Bridge, Elevator Express (4 lane roads between Dhaka and Chittagong) and the construction of a Power Plant for the Bangladesh Power Development Board of these projects would create a huge demand for cement in the market in the near future creating more opportunities for these companies to accommodate their increasing production capacities and to earn profits.

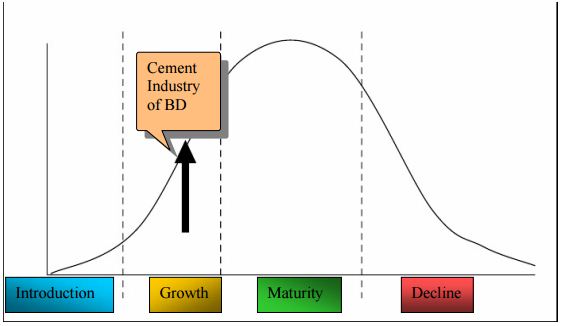

By analyzing all the information mentioned above, it can be said clearly that in the life cycle of a product (industry in this case), in Bangladesh; the cement industry is in the growth stage currently. This phase of the industry has been illustrated in the graph below.

The product life cycle model can help to analyze the different mtaurity stages of a product or an industry.In the diagram above, it can be seen that the cement industry of Bangladesh is currently in the Growth stage of the product life cycle. According to this diagram, the facts related to the cement industry of Bangladesh can be related. At present, the sales of cement are increasing due to an enormous demand for cemnet in both the local and foreign markets.Moreover, the competitors in this industry are also increasing day by day altthough some smaller companies are shutting down but the bigger companies are getting more bigger and competing with the existing players in the market.There is also a huge prospect for more growth of these companies and the industry itself in the near future. Thus, the product of the company ( cement produced by PMCL) and also the whole cement industry in Bangladesh is at the growth stage.

It has been predicted by the analysts of the industry that in the long run; around the year of 2050, concrete /cement structures are likely to be replaced by steel structures. These prediction has ben made based on a number of confidential information and also by observing the trends of infrastructural developement in other deloped and/or developing countries in the world. However, according to them, this prediction does not pose much threat to the cemnet companies of the country as there is still a lot of time left in hand and whereas these companies have a long way to go.

Competitor’s Analysis

There are many competitors of Premier Cement. Among them are both the established local brands and also some multinational brands. The companies which are the competitor’s of Premier Cement are mainly those companies which are on the higher rating scale of Premier Cement like Shah Cement, Heidelberg Cement, Meghna Cement Mills ( Bashundhara Group), Holcim BD ltd, Seven Circle, Unique Cement Industries, M.I. Cement Factory and Akij Surma. Be it in terms of brand image, product quality or sales, each of these companies have their own distinctive feature for which they are positioned in a higher rank than Premier Cement. Thus Premier Cement sees these companies as their competitors as they are constantly fighting with these companies to reach their desired position in the market. However the cement companies which are just below Premier Cement in ranking are also viewed as competitors and the company always keeps a look out for these companies’ activities. It is so because these companies can take the position of Premier Cement any day. Thus both the cement companies performing better than Premier Cement and the ones performing at the same level as Premier Cement are the competitor’s of the company.

Current Scenario of Premier Cement & the other cement companies

As per the Ranking of the Cement Companies (shown above) it can be seen that Premier Cement is on the ninth position among the top ten cement companies (both local and foreign) in the Cement Industry of Bangladesh. Although varied in ranking but almost all the top cement companies more or less follows a similar structure in terms of their functional activities; in order to survive in the industry. To have an in-depth idea of this existing phenomenon, the current activities of Premier Cement in different areas and that of the overall cement industry has been discussed below in details.

PRODUCT OFFERINGS: Cement Industry

Before 2002, all the cement companies of the country used to produce Ordinary Portland cement which was mostly clinker based. However, since 2002, all the cement companies have brought differentiation in their product and are now involved in making Composite Cement. Holcim Bangladesh was the first company to launch this type of cement in the market.

PRODUCT OFFERINGS: Premier Cement Mills Ltd

Like other Cement companies, PCM is involved in the manufacturing of Ordinary Portland cement and the Portland Composite cement. However, they make the Portland Pozzolana Cement for exporting. This type of cement is similar to the Portland Composite Cement only with some difference in the composition the overall cement.

PRODUCTION CAPACITY: Cement Industry

Currently, 31 cement companies are operating in Bangladesh. The present and the upcoming production capacities of the running cement companies (as per the data of August 2010) are given in fig.4.4.From the given figures, we can see that Shah Cement which is the top Cement Company in the industry, both among the local and foreign companies has the highest production capacity which amounts to 2,700,000.00 in MT/year and their upcoming capacity is also the highest among upcoming production capacities of other companies which is 1,800,000.00 MT/year. Their project is an ongoing project. Premier Cement has the third highest production capacity as per this year 2010 which amounts to 1,200,000.00 MT/year similar to the capacity of Lafarge Cement and Akij Cement.

PRODUCTION CAPACITY: Premier Cement Mills Ltd

Production Capacity refers to the volume of products that can be generated by a production plant or enterprise in a given period by utilizing the resources available currently Premier Cement owns two ball mills whose production capacity is 2000TPD each. The company produces a total of 4000TPD each day by using these two ball mills.

The present production capacity of the ongoing project of the year 2010 is 1,200,000.00 tons.

TECHNOLOGICAL IMPACT: Cement Industry

There are mainly three matters which are taken into consideration while assessing the Technological Impact of the Cement companies in Bangladesh. These are:

- The Technology used to make the product

- The origin of the equipments/ machineries which are used to make the products

- Other Technological aspects of a company related to IT which mainly includes the software used by the country and their accessibility and presence via internet.

Till the year 2002, Ordinary Portland Cement (which is only clinker based) was produced all over the country by all companies using the American Standard Method (ASTM).

From the year 2002 onwards, differentiation was brought to the type of cements produced in the country by using the European Standard Method (ESTM) through which composite cement consisting of various composition and layers were manufactured. Today all the cement companies of the country uses the European Standard Method to manufacture their products. Usually the standard of Portland cement varies from country to country and thus, there is no universal international standard. As a result, all over the world cement companies in each countries uses the same method (either ASTM or ESTM).

Moving on, out of the top ten companies on the cement industry of Bangladesh Premier Cement, Cemex and Heidelberg Cement uses the European Machineries and European Technologies to manufacture their products. Apart from these companies, the remaining companies uses the machineries and technologies adapted from the Asian regions such as China, Japan etc. It should be mentioned here that cement companies who have their own power generation plant are self sufficient. These plants run on gas and problem arises as there is a scarce supply of gas which interrupts the smooth operation of the plants. This is a problem faced by all the cement companies of the country. The shortage of power supply is also another factor which interrupts the smooth flow of operation of the companies.

Lastly, the application of information technology varies from one cement company to another. Companies use different programs and software to carry out the various tasks of their organization. As this is a confidential issue, thus much information could not be obtained regarding the various programs, software and applications used in each of the cement companies. The other important side of technology related to the availability of information and accessibility of a company through internet varies greatly from one company to the other. Information about almost all the cement companies of the country is available on the online yellow pages of Bangladesh. However, the website and the webpage of these companies are not of the same standard. Cement companies like Heidelberg, Holcim, Shah, Lafarge and Seven Circles have their own individual webpage where detailed information about the company can be easily found via internet.

TECHNOLOGICAL IMPACT: Premier Cement Mills Ltd.

Just like other cement countries of the country, Premier Cement Mills uses the European Standard Method to manufacture their products.

The company has an added advantage over most other cement companies they are one of those companies besides CEMEX and Heidelberg Cement who possess European equipments and uses the European technology to make their products. The specifications of the equipment technologies used by PCM have been discussed above.

The IT department of PCM is responsible for organizing and managing the various software and programs used by the employees of the company. All the employees of PCM (referring to the Dhaka and the Chittagong branch) are well acquainted with the basic computer skills, however most of the employees of the corporate office of PCM are trained to use and apply sophisticated and modern software required for their work areas.

Like other companies, Premier Cement is also enlisted on the online yellow pages of Bangladesh. The company has their own website and the address is www.premiercement.com. However, a new and a better website is under construction now which will be launched very soon.

PRICING: Cement Industry

The pricing of cement of various companies are very close to one another. (refer to figures Market price in Dhaka & out of Dhaka). There are a number of components which are taken into consideration while price fixations of cement bags are carried out. The components are discussed below.

Cost of the raw materials and production of the cement

To start with, the cost of producing the cement itself is taken into account. This includes the cost of importing raw materials, cost of production and the cost of packaging all inclusive of other fixed costs consisting of inventories and human resource required for production. The market demand also plays a dominant role in the price fixation of cement. The supply of the raw materials and supply of cement by other companies in the market in addition to the market demand of the product also determines the final price of the product. When the demand of their product is high, the price of their product is also increases and vice versa.

Seasonal demand of the product

The other important factor which has an effect on the changing price of the product is that of the seasonal demand of the product in the market. There are mainly three dominant seasons in terms of demand of cement in the cement industry. They are as follows:

- Peak Season: January to April/ May

- Dull Season: June to September

- Off Season: October to December

In the cement industry, January to April which sometimes also stretches till May is considered as the peak season when the demand of cement in the market is very high. As per the climate of Bangladesh, there is little or no rainfall in the country thus it is an ideal time for starting the work of constructing buildings and other infrastructural development projects during this season. As the demand of cement is high during this time, as a result the price of the products of Premier Cement is also higher than that compared to the rest of the year. This is also true for other cement companies operating in the country.

The month of June to September is considered as the dull season in cement industry when the overall sale of cement is quite low compared to that of the peak season. This is the time of the year when rainfall is most evident in our country. Rather than constructing buildings, this time of the year is mostly used for curing. Curing is one of the most important steps in concrete construction. Curing mainly increases the strength and durability of concrete to a great extent. The concrete hardens as a result of hydration which is a result of the chemical reaction between cement and water. However, hydration occurs only if water is available and the temperature of the concrete stay within a suitable range. The rainfall in this dull season helps the concrete surface to stay moist naturally and allows the hydration process to take place.

The Off season for the cement industry usually starts from October and ends in December. During this time the sale of the cement is normally the lowest or almost close to nil. This is also the time just before the peak season. From past observations, it has been seen that usually the other materials related to cement (mainly referring to the other building materials) are not available during this time of the year. This is also another prevailing reason for this period of the year to be regarded as the dull season. Taking this situation into consideration, the price of the cement of almost all companies in Bangladesh is usually the lowest compared to that with the other two seasons due to the fall in market demand and sales.

Price of competitor’s products

Currently, 31 cement companies are operating in the cement industry of Bangladesh who are producing similar products. Due to the presence of homogeneous products in the market, price war is a sensitive issue in this industry which exists from time to time in the cement market. Another component which is taken into consideration while fixing the price of cement bags is done by observing the price of the competitor’s products.

Others like government tax, VAT etc.

Other uncontrollable elements such as the inflation rate, chance in exchange rate and the tax and/or VAT imposed by government are also some elements which determines the final price of cement. The increase of these monetary elements makes the price of cement rise up and vice versa.

PRICING: Premier Cement Mills Ltd.

Premier Cement Mills Ltd is a large company who gives great importance and time to the price factor of their products. The company follows a very simple but a well defined pricing strategy for deciding the price of their products. As the cost of producing each bag of cement is known, the company then adds a price tag to their product by following the market leader of the Cement industry. As a result, the price of their product is fixed by following the market leader of the cement companies as their benchmark in each of the regions.

The price of Premier Cement varies from region to region. For an example, the market leader of cement in Dhaka is Shah Cement. Thus the price of the product of Premier Cement in Dhaka is fixed depending on the price of Shah Cement in Dhaka. On the other hand, currently Ruby Cement is the marker leader in Cox’s Bazar. Thus the price of Premier Cement products in Cox’s Bazar is fixed as per the price of Ruby Cement products in Cox’s Bazar. This strategy does result to a varying price of the same product from one region to another but however, there is never a gap of more than Taka 10 within the country. Although this is the core strategy of the final stage of price fixation of the company, however there are also some other important components taken into account while the price of the products are fixed.

Currently, the standard price of one cement bag produced by the multinational cement companies ranges within the price of taka 370 to taka 390 per bag. On the other hand, the price of a cement bag produced by the local companies ranges within the price bracket of Tk.340 to Tk.365. At present, the price of Premier Cement in Dhaka is taka 355 per bag.

Although Premier Cement follows a clearly defined pricing strategy for fixing the price of their products, however the components mentioned above in addition to other controllable and uncontrollable elements (like inflation rate, chance in exchange rate and the tax and/or VAT imposed by government) do create situations where the price of the company’s product has to undergo changes from time to time. As mentioned earlier, the market demand and supply plays a prevailing role in the price fixation of the products of Premier Cement. Similarly the change in the price of the raw materials of cement also compels the company to alter their prices accordingly from time to time.

The landing (LP) and the delivery price (DP) of Premier Cement and other cement companies in Dhaka and outside Dhaka are shown given in table

CUSTOMERS: Cement Industry

The big cement companies of Bangladesh (referring to the top 15-20 companies) cater their products and services to a similar line of customers. The customers of the companies are also the players of the distribution network of the company. The categories of customers are as follows:

- Distributors

- Dealers

- Retailers

- Industrial Personal/ Personals

- Large Contractor

- Real Estate & Developers

- Home owners

- Clients and customers in export areas

CUSTOMERS: Premier Cement Mills Ltd.

Just like other big cement companies, Premier Cement Mills also caters to the same customers with their products and services. As seen above, these customers are players in the distribution network whom the company attracts by implementing their marketing activities and then eventually reaching them through their distribution networks

PROMOTIONAL ACTIVITIES: Cement Industry

Promotion involves disseminating information about a product, product line, brand, or company. It is one of the four key aspects of the marketing mix As the market is becoming more and more complicated, creative and attractive promotional strategies are considered as the key to stay in the scenario. The specification of these four variables creates a promotional mix or promotional plan. A promotional mix specifies how much attention to pay to each of the four subcategories, and how much money to budget for each. A promotional plan can have a wide range of objectives, including: sales increases, new product acceptance, creation of brand equity, positioning, competitive retaliations, or creation of a corporate image. This is another sector where the cement companies compete greatly with another. Both electronics and print media are used by the companies to promote their products and services to the customers. Some common promotional tools that are used by almost all the top cement companies of Bangladesh are as follows:

- Newspaper Advertising

- Promotional Campaigns

- Wall paintings

- Signboards and light boxes

- Customized Accessories

- Events

- Sponsorships

- Television

- Internet

- Radio

- Magazines

Critical Observation and Recommendation

During the period of my internship at PMC Ltd, I found some critical areas of the company while working with them. I took these observations into consideration and suggested some recommendations to the PMC Ltd authorities so that they aware of a thirds person’s point of view, which they might want to work with in the near future to bring about some improvements in their working areas.

Observation 1: Unstructured HR Department

While working with the HR department, I noticed that the tasks of the entire department lacked a proper arrangement or structure. The flow of work within the department is not very systematic and neither is it being performed in an orderly manner. These drawbacks are understandable as this department is very new and still under the process of development and improvement. However, their shortcomings during this period create room for confusion and mismanagement which if not handles properly may affect the company badly in the future.

Recommendation:

As this is a very new department in the company, the employees and the authorities of the department are likely to face problems which eventually results to some mismanagement. This I think can be solved if either of the two recommended options is taken into consideration. First of all, the people responsible for the HR department should arrange small training sessions for all their employees working in their corporate office so that all of them can have a better understanding of how the department functions. This would also give them an opportunity to clear out their queries and suggest new ideas for the department. The company can also invite experienced HR personals especially those who have been involved with the cement industry to conduct these training sessions. The chances of an experienced person (in the field of HR) having the ability of comprehending and managing the situation in a better way and to provide useful advices is more likely. Secondly, the company can hire an external HR consultant for a period of time; that can guide them and help them grow till the department is not established properly.

Observation 2: Standardized facilities for factory workers

During my visit to the factory of PMC in Muktarpul, Munshiganj and as per my discussion with the Operations supervisor, I found out that the factory workers are provided with safety and medical facilities. However after much analysis, I figured out that such facilities provided to the workers are similar irrespective of the kind of work that each of these workers was associated with. I personally feel that this may not be helpful for the workers. As there are a number of stages involved in the production process of cement, each of these stages also involves different type of works which involves different type of risks, thus following a set of standard facilities to workers the may not be very helpful.

Recommendation:

I have mentioned this issue to the concerned authorities when I was informed that the authorities responsible for these areas are already working out ways to provide different kind of medical, health and security facilitations to their factory workers depending on the nature of their work. For an example, the person responsible for lab testing does not require a medical/health benefit like that similar to a worker involved in grinding the cement in the factory. I had participated in a small meeting which was held to discuss on these issues.

Observation 3: Unattractive website

I saw the old website of Premier Cement Mills which I think looked a little unattractive and lacked sufficient and relevant information compared to the website of the top cement companies of the country.

Recommendation:

The new website of Premier Cement Mills is under construction. While working with the IT department, I had the opportunity of having a glimpse of the new website of the company which is still under construction. I shared some of my ideas with the team members regarding some of the things that they could add to their new website so that they can come up with a better webpage this time, which will be of the same standard at least; if not better than that compared to their competitors. With the widespread availability of the internet, everything is just a click away from us and the webpage of a company creates the first impression about the company in the customer’s mind.

Therefore, it is very important for PCM to work hard towards creating an affirmative impression about their company to the viewers of their website from all around the world.

Observation 4: Giving BUET reports in Bengali newspapers mostly

As I interned in PMC Ltd, I found out that the company publishes their BUET reports and other test reports in Bengali newspapers only. Although this promotional activity has benefited the company to a great extent as it attracted the attention of many potential buyers and also helped them achieve a brand image and enhance their reputation.

However by limiting the publishing of these reports in only Bengali newspapers, the company is missing out on a whole segment of their target and potential customers who have access to English newspapers only.

Recommendations:

The company allocated almost 9 crore taka this year from their budget for marketing and promotional activities only. I have thus suggested the marketing head to start promoting their tests results and reports in English newspapers as well so that more people are aware of the credential of their products.

Observation 5: Old Corporate Video

I attended some corporate meetings with the directors, head of the departments and with externals while I interned with PMC Ltd. This gave me an insight to the business environment of the company and how they conduct formal meetings with externals.

Although the presentations in the meetings very impressive, however I feel that the corporate of video of PMC should be changed. The video that is shown to the externals even today was made in the year 2005. Though it may be a very minor flaw, but I feel that the screening of this video provides an impression about the company and thus, something should be regarding this.

Recommendation:

PMC Ltd should make a new corporate video for their company immediately. Although most of the content and the facts presented in their current corp. video is valid even for today, however they should make a new one by using interesting footages, better picture quality and more added information about the company. I have also recommended the authority to make dub their video in English or to add English subtitles to their video. As the company deals clients from big corporatism and industries and are also engaged in export with foreign countries, I feel that it is necessary for them to have their video in this International language.

Observation 6: Lack of up to date Information

While working with the Customer Service team, I received some e-mails and phone calls which stressed on some problems of PCM which was of similar nature. According to some of the clients, there was unavailability of up to date information about the company.

Recommendation:

I have discussed about this problem to some of the members of the Customer Service team because if this problem lingers, then the clients may become dissatisfied with PCM which may result to loss of customers in the long run. One of the main reasons why this problem is taking place is due to the lack of a proper website of the company. As long as the new website is not ready, the company should put more emphasis on maintaining their PR and relations with customers. They should also increase the frequency and the amount of their news and advertisements being published on newspapers and magazines so that the clients are always up to date about the company.

Observation 7: Miscommunication and misinterpretation of messages exchanged between an employee and the customer.

PMC Ltd caters to a wide range of customers. While working with the Customer Service team, I was asked to handle some phone calls of the clients to take their calls for complains and feedback. While doing this work, I realized that only should each customer be attended differently over the phone but also the way to communication verbally with the varying type of customers requires alterations depending on the type and background of the customer. At times, messages were interpreted incorrectly and some confusion took place due to the inability to understand the speech of one another over the phone. This can lead to a loss of time and sometimes to dissatisfaction for both the receiver and the caller.

Recommendation:

To deal with this situation, I would suggest PMC to first increase the number of people working in this department immediately. They should place employees having varying type of dialect and verbal communication skills. For an example, they can assign a person with good spoken English and proper Bengali to deal with the corporate clients and those residing abroad. On the other hand, they can assign another employee having the ability to understand different type of dialects of the country (e.g. Chittagong, Khulna, Barisal etc) to deal with customers calling from outside Dhaka. This recommendation may sound very racist but if this is done, then such miscommunication can be avoided very easily.

Conclusion

Ever since I started taking interests in internship, I learnt that most of my seniors were doing their internships in telecom industry, financial institutions and FMGC companies. Contrary to this prevailing trend, my decision to join a cement company was quite different. However starting my internship with little or rather no knowledge about the cement industry of the country, I really did not know what to expect from this internship.

I really did not think that my experience with Premier Cement Mills Ltd would be so interesting and enriching.

Although I worked for a short period of time with the company, it was a good thing that I got an opportunity to work with almost all the departments of the corporate office of PMCL. In terms of the number of human resource working in the corporate office of PMCL, it is not very high and thus everyone is working with almost everyone in one way or the other. This close interaction benefited me as I was able to gain a lot of knowledge about the company and the industry by observing, performing the tasks that I was assigned to and by working with the employees of PMCL. I feel that the size of the company and my exposure to all the departments of the company actually helped me to gain an overall idea of the operations of the company and the industry in Bangladesh.

This would not have been possible if I was engaged in a particular department or a very big company. My field visit to the factory of the company in Muktarpur, Munshiganj and to the engineer’s and the Mason’s meetings were also very interesting where I gained some practical knowledge. Overall, my experience of doing my internship with PMCL was quiet enjoyable.

The cement industry is one of the newer but a promising industry of the country. There is a huge room for growth of this industry in Bangladesh in the near future. As a result, I feel that a lot of students can actually think of building their career with the cement companies of the country. I would be glad to contribute as well if given a chance as this industry not only promises to build people’s homes but also contribute to the overall development of the country.