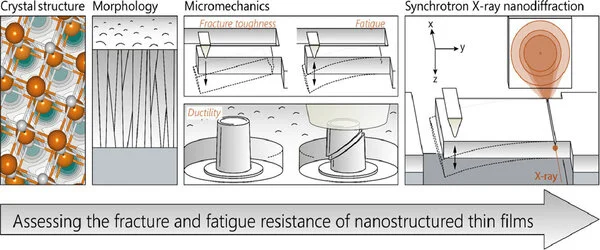

Ceramic coatings that are extremely thin can completely alter the properties of technical components. Coatings are used to improve metal resistance to heat and corrosion, for example. Coating processes are important for large turbine blades as well as extremely stressed tools in manufacturing technology.

The University of Vienna (TU Wien) has now investigated what factors influence the stability of such coatings. The results, obtained in part at the DESY synchrotron in Hamburg, are quite surprising: ceramic layers degrade in a completely different way than metals. Material fatigue plays little of a role; the intensity of extreme load peaks is the deciding factor. This discovery will alter the method of measuring thin films in the future, allowing them to be more resistant.

The study is published in Acta Materialia.

Stressed millions of times

“In many applications, periodic loads are a big problem,” says Prof. Helmut Riedl, head of the Applied Surface and Coating Technology research group at the Institute of Materials Science and Technology at TU Wien. “If you expose metal components to a certain force over and over again, changes occur on a microscopic scale.” Some atoms may shift, layers are formed that can slide past each other, and tiny cracks can develop and ultimately lead to the fracture of the entire component. Such material fatigue effects are ubiquitous in engineering, and they are well-studied.

Ceramic coatings are often only a few nanometers to 10 µm thick, their behavior is completely different from that of a solid piece of ceramic.

Lukas Zauner

What happens to thin coatings under stress, however, is less clear. “Ceramic coatings are often only a few nanometers to 10 µm thick, their behavior is completely different from that of a solid piece of ceramic,” says Lukas Zauner, who is working on his dissertation in the Applied Surface and Coating Technology Research Group.

To gain the deepest understanding of this behavior, completely new measuring methods were developed at TU Wien: Instead of testing metal and ceramic coating together, as is usually done, the team left out the metal, produced extremely thin samples of various ceramic materials typically used in thin-film technology and exposed them to various loads in a precisely defined way—over and over again, up to ten million times.

X-rays at the synchrotron

In order to find out exactly whether the atomic structure of the ceramic changes, as a result, the team took the experimental set-up to Hamburg: there, extremely well-focused X-rays are available at DESY’s synchrotron, which can be used to examine various points of the sample during the loading experiment. Even tiny changes in the crystal structure or in the distance between neighboring atoms should be detectable in this way.

But surprisingly, these measurements showed: The ceramic practically does not change. Even millions of load cycles do not lead to material fatigue. “Standard ceramics would fatigue according to certain patterns, similar to the kind of fatigue we know from metals. But these extremely thin layers do not show this behavior,” says Helmut Riedl. “Their microstructure is the same at the end as it was at the beginning.”

This means that the durability of the thin layers is determined exclusively by their fracture toughness: If you exceed a load limit characteristic of the material, then the layer is destroyed—suddenly and irreversibly. However, all loads below this limit are not a problem, they do not age the ceramic layer, and they have practically no effect.

New research strategies

“Of course, this also changes the strategy how research projects for new, improved ceramic coating materials are designed,” says Helmut Riedl. “You don’t have to do lengthy long-term tests, it’s enough to find out by a simple load test which material breaks under which force. You don’t have to worry about how to possibly alleviate fatigue effects in the material, you just have to find materials with the highest possible fracture toughness—even this is not a simple task on its own.”

The team has already been able to find an excellent candidate for this: a certain form of chromium diboride proved to be surprisingly resistant in the tests. This paves the way for the future, promising research gaining the greatest success.