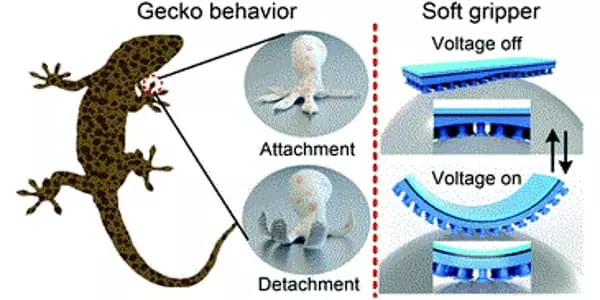

Researchers combine adhesives based on gecko toes with a customized robotic hand to create a robotic gripper with a delicate strength. There is a common foe across a vast array of robotic hands and clamps: the heirloom tomato. You may have seen a robotic gripper deftly pluck an egg or smoothly palm a basketball – but, unlike human hands, one gripper is unlikely to be able to do both, and a key challenge remains hidden in the middle ground.

“You’ll see robotic hands do a powerful grasp and a precision grasp and then kind of imply that they can do everything in between,” said Wilson Ruotolo, Ph.D. ’21, a former graduate student in Stanford University’s Biomimetics and Dextrous Manipulation Lab. “What we wanted to address is how to create manipulators that are both dexterous and strong at the same time.”

This goal has resulted in “farmHand,” a robotic hand developed by engineers Ruotolo and Dane Brouwer, a graduate student in Stanford’s Biomimetics and Dextrous Manipulation Lab (aka “the Farm”) and detailed in a paper published Dec. 15 in Science Robotics. The researchers demonstrated that farmHand can handle a wide range of items in their testing, including raw eggs, bunches of grapes, plates, jugs of liquids, basketballs, and even an angle grinder.

The first applications of gecko adhesives were for climbing robots, climbing humans, or grasping very large, very smooth objects in space. However, we’ve always intended to use them for more practical purposes. The problem is that it turns out that gecko adhesives are actually very fussy.

Wilson Ruotolo

FarmHand benefits from two types of biological inspiration. While the multi-jointed fingers are reminiscent of a human hand, albeit a four-fingered one, the fingers are topped with gecko-inspired adhesives. This grippy but not sticky material is based on the structure of gecko toes and has been developed over the last decade by the Biomimetics and Dextrous Manipulation Lab, led by Mark Cutkosky, the Fletcher Jones Professor in the School of Engineering and senior author of this research.

Using the gecko-adhesive on a multi-fingered, anthropomorphic gripper for the first time was difficult, requiring special attention to the tendons controlling farmHand’s fingers and the design of the finger pads beneath the adhesive.

From the Farm to space and back again

The gecko adhesive, like gecko toes, creates a stronghold through microscopic flaps. When these flaps make full contact with a surface, they generate a Van der Waals force, which is a weak intermolecular force caused by subtle differences in the positions of electrons on the outsides of molecules. As a result, the adhesives can grip tightly while requiring little actual force. Another advantage is that they do not feel sticky to the touch or leave a residue.

“The first applications of gecko adhesives were for climbing robots, climbing humans, or grasping very large, very smooth objects in space. However, we’ve always intended to use them for more practical purposes” Cutkosky stated. “The problem is that it turns out that gecko adhesives are actually very fussy.”

The fuss is that the gecko adhesives must make a specific connection with a surface in order to activate the Van der Waals force. This is simple to control when they are smoothly applied to a flat surface, but much more difficult when a grasp relies on multiple gecko adhesive patches contacting an object at different angles, as with farmHand.

Pinching and buckling

Below the adhesives, farmHand’s finger pads assist in addressing this issue. They are constructed with a collapsible rib structure that buckles with little force. The ribs consistently buckle regardless of location or angle of contact, ensuring equal forces on the adhesive pads and preventing any single one from slipping prematurely.

“If you move these ribs, the buckling produces a similar force regardless of where you start,” Brouwer explained. “It’s a simple, physical behavior that could be used in areas other than robotics, such as shoe tread or all-terrain tires.”

The tendons of the hand are also important because they allow for a hyperextended pinch. Many robotic hands and clamps pinch objects in a “C” shape, similar to picking something up with only the tips of your fingers, but farmHand pinches with the ends of its fingers pressed pad to pad. This provides more surface area for the adhesives to work with.

It was especially difficult to get the design just right because existing computer simulations have difficulty predicting real-world performance with soft objects – another factor in the heirloom tomato problem. The researchers, on the other hand, benefited greatly from being able to 3D print and test many of the hard and soft plastic components in relatively short cycles. They even go so far as to say that their success would not have been possible – or would have been much slower – only five years ago.

Further enhancements to farmHand could include feedback features that help users understand how the hand is gripping and how it could grip better while in use. The researchers are also thinking about commercial applications for their findings.